One of the pleasures of working in agricultural extension is when you’re able to help a grower solve a problem. This was one of those happy occasions. An orchardist purchased a Lipco multi-row recycling sprayer and wanted help evaluating their spray coverage.

We worked in 3.7 m (12 foot), mature, high-density Royal Gala trees. The sprayer was driving at 5.0 km/h (3.1 mph), operating at 11 bar (160 psi) using orange Albuz 80 degree air-induction flat fans. This resulted in about 350 L/ha (~37 gpa).

This grower wisely invested in the air-assist option, which produces a vertical plane of somewhat laminar air to entrain the spray and carry it into the centre of the target canopy. Whatever spray blows through the tree should impact the opposing shroud and get recycled back to the tank. All in all, how could you miss?

…we managed to.

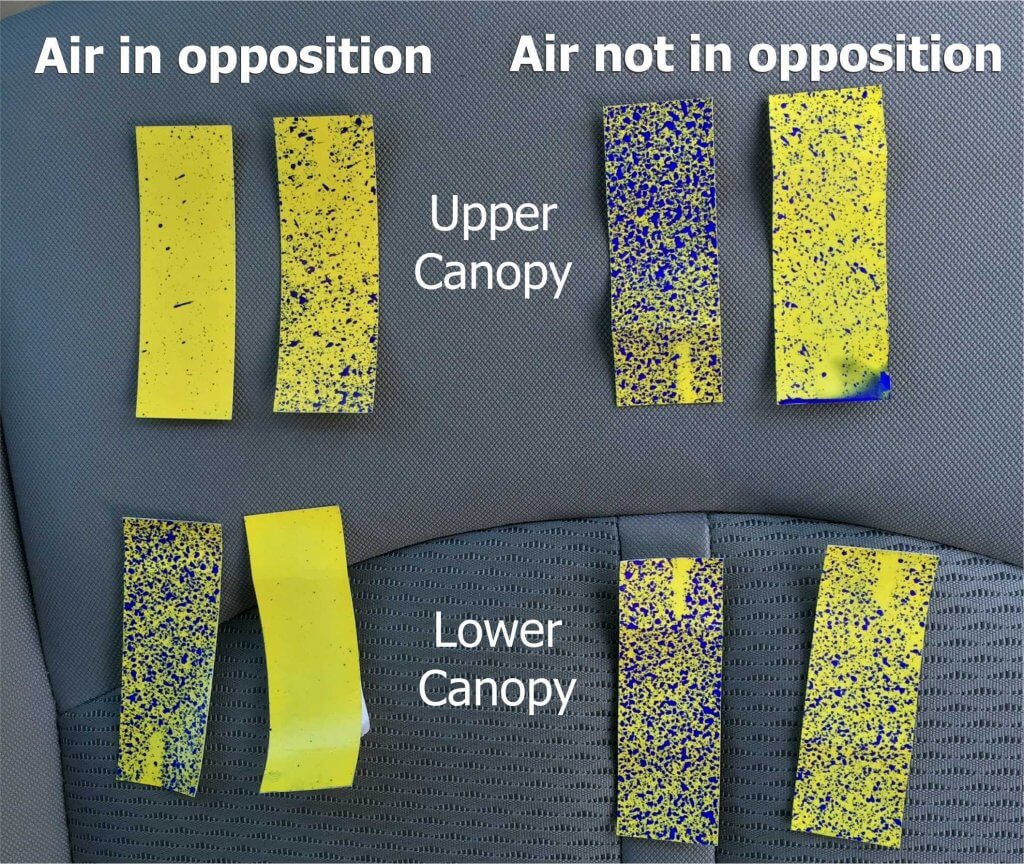

Water sensitive papers were placed back-to-back facing each alley (in other words, facing the spray booms). Despite our best efforts, each pass resulted in inconsistent coverage. Papers were replaced in the same location and orientation for each pass and no settings were changed. Nevertheless, sometimes a paper got spray and sometimes it didn’t. What was going on? It was as if the two air streams were interfering with one another – almost cancelling each other out.

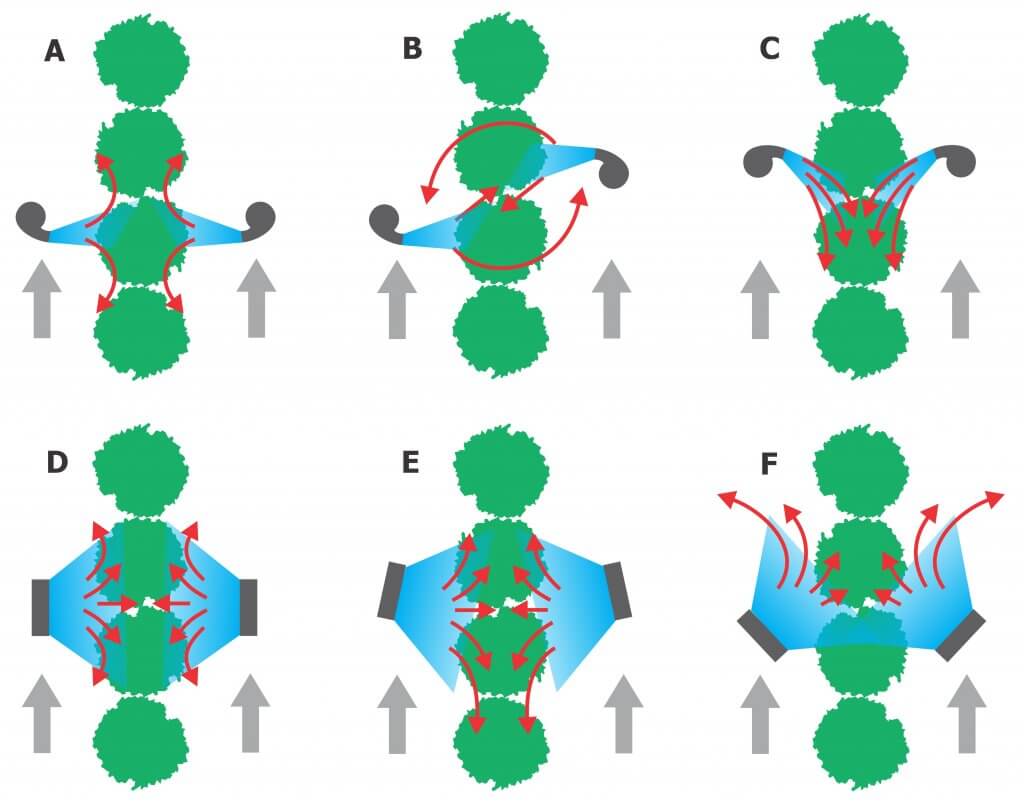

Where possible, do not position laminar air outlets in direct opposition. The convergence creates a high-pressure zone that reduces spray penetration. Some sprayers are designed to avoid this by staggering air outlets one ahead of the other. Laminar flows will deflect unpredictably around this pressurized area and carry droplets back out of the canopy. Unless the canopy is particularly narrow and sparse, turbulent air handling systems do not typically create this problem. In both cases, canopy penetration is improved when fans are staggered and/or are angled slightly forward or backward.

We decided to turn the outer boom/shroud/fan assemblies 10˚ backward by loosening the four bolts at the top of the gantry (see below). This minor change in configuration improved spray coverage significantly. Increasing the angle beyond 10° might have caused the air wash to trail along the canopy face and would have made sprayer turns difficult at the row ends.

We replaced the water sensitive papers and ran another pass. The operator later told me he could see the leaves and branches rustling in the row where we made the adjustment, but not in the unadjusted row. The result on water-sensitive paper was dramatic.

Since experiencing this in 2013, I have been told that the Lipco instruction manual advises against air in direct opposition. It was a poorly translated and somewhat obscure sentence buried in the manual, but I concede that it was there. Determine whether your sprayer produces more laminar or more turbulent air, and explore how their relative orientation impacts canopy penetration.