Excepting air shear and centrifugal style nozzles, most airblast sprayers employ nozzle bodies designed to except hydraulic nozzles distributed evenly along the booms. Nozzle caps compress the nozzle against the body to force the spray mix through the nozzle orifice. Nozzle bodies are not all created equal.

Double Outlet Roll-Over Nozzle Bodies

Double outlet roll-over bodies (pictured below) allow the operator to quickly switch between two nozzles mounted in each position. This is convenient when alternating from dilute to concentrated applications, or changing the spray distribution from block to block.

The roll-over feature can act as a shut-off and facilitate fine-tuning the orientation +/- 15° from centre. When roll-overs are new there is an audible ‘click’ when they reach 15° to alert the operator that turning them any further will interfere with flow. This feature fails as bodies wear.

Single Nozzle Bodies

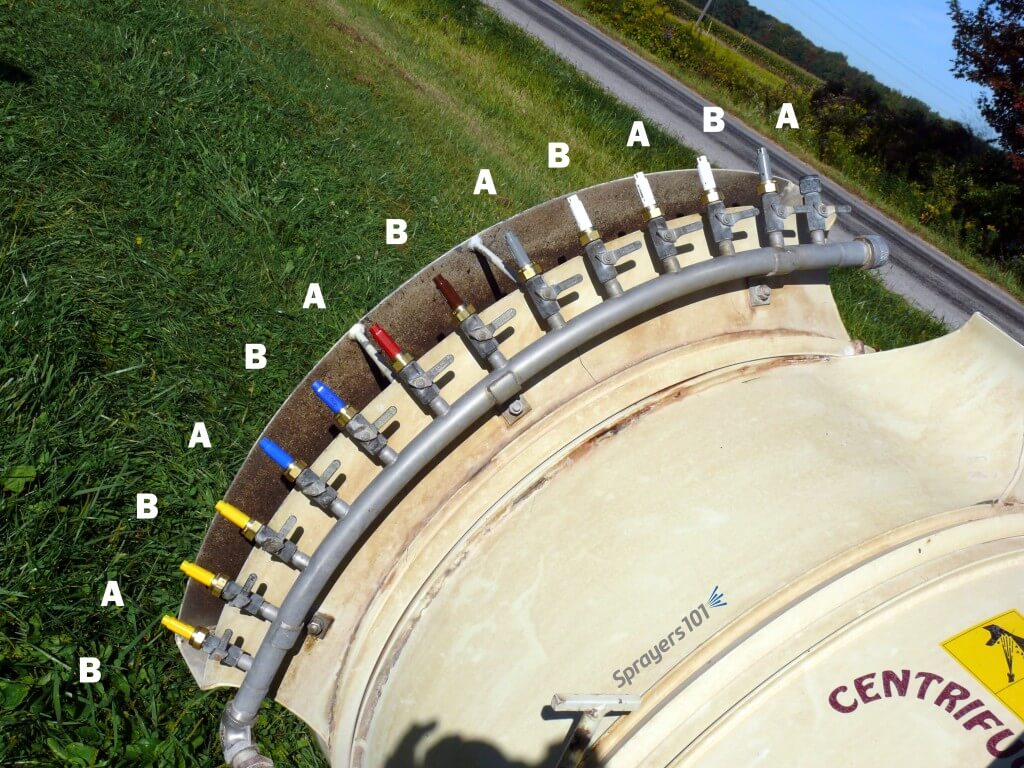

Some sprayers employ single nozzle bodies featuring screw or lever-style quarter-turn shut-offs. Some sprayers, like the Turbomist featured below, double the density of the bodies along the boom, arranged in an alternating A-B pattern. The operator shuts off each alternate nozzle, perhaps using the A’s for dilute and the B’s for concentrate applications. The density gives the operator the ability to “double up” in positions along the boom if more spray is required.

Still others may affix the nozzle bodies to the deflectors (like the Air-O-Fan below), permitting the operator to orient the air and nozzles at the same time.

Check Valves

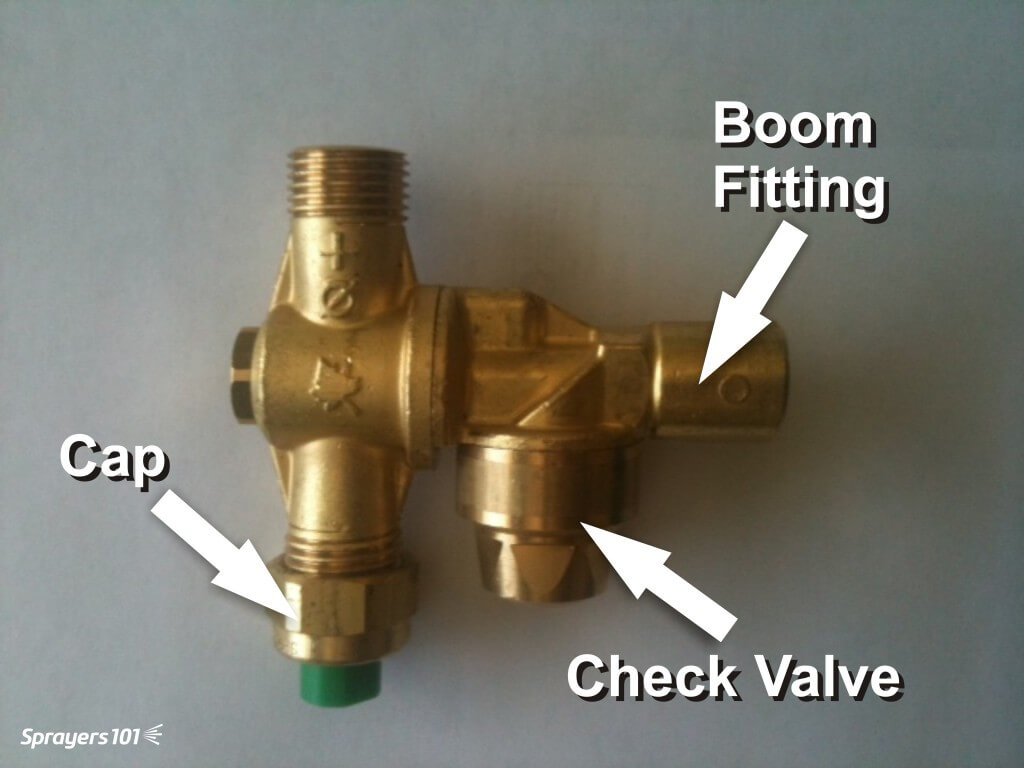

In my opinion, it should be mandatory for nozzle bodies (or at least booms) to have diaphragm check valves. When pressure drops below ~15 psi the valves shut to prevent the boom from draining (see image below).

Booms don’t just drain in the yard. Operators shut off the outside boom when turning at the end of a row. Without check-valves, the boom drains through the bottom nozzle, wasting pesticide and causing repeated and unnecessary point-source contamination. Further, it takes a moment for the boom to refill, meaning the top nozzles may not be spraying at the beginning of each row.

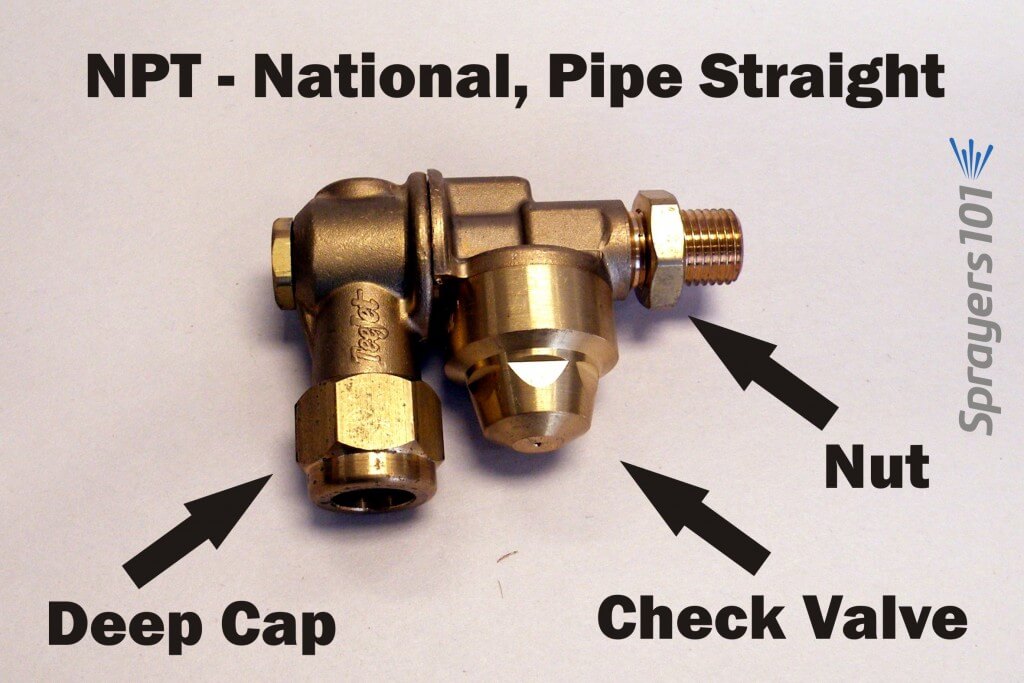

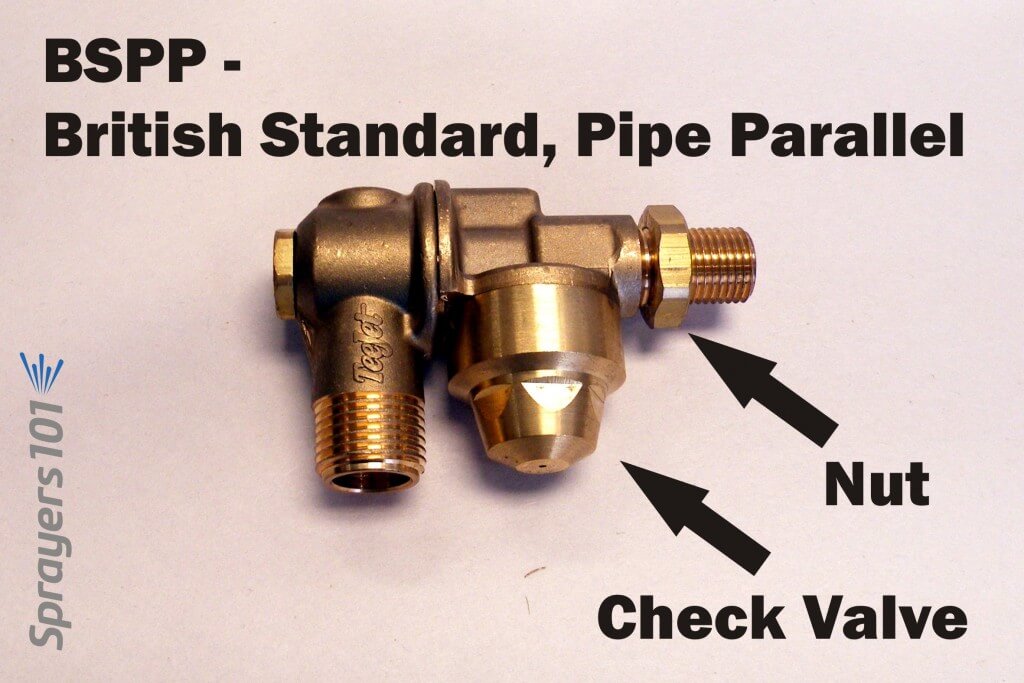

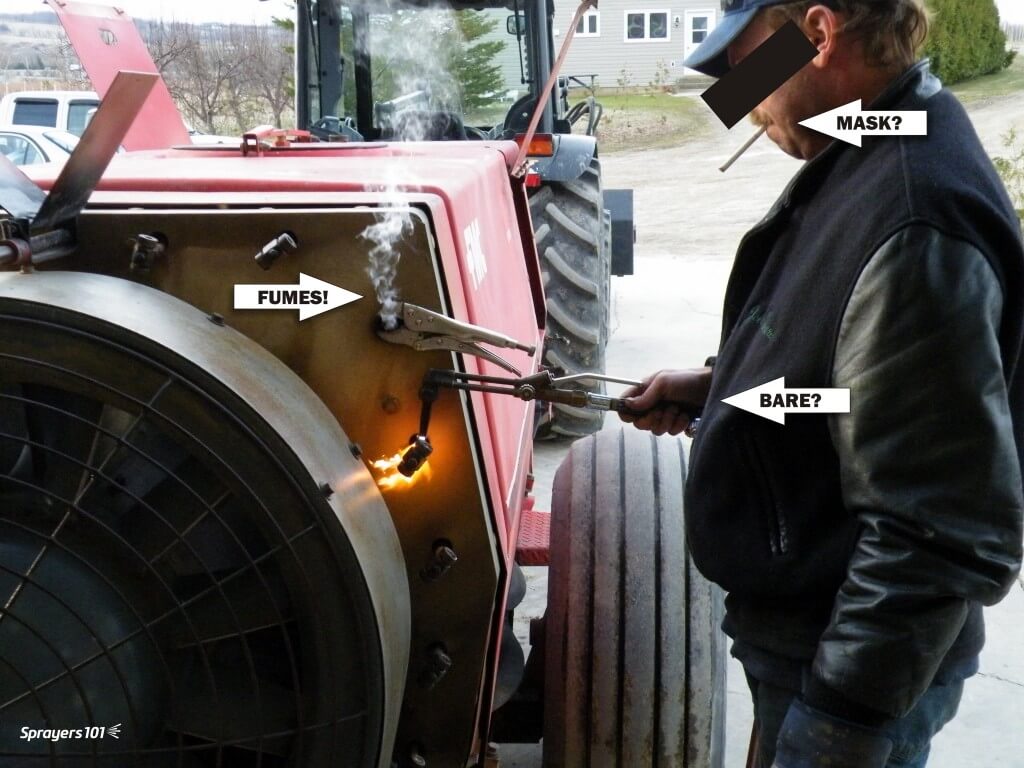

You may be tempted to purchase mesh nozzle strainers with built-in ball valves. They can work as an alternative to integrated nozzle body check valves, but they plug and fail with irritating regularity. The image below shows a creative method for installing check-valves on single nozzle bodies. The nozzles protrude and the check valve seems too close to the shut-off, but reputedly this works.

Thread Types

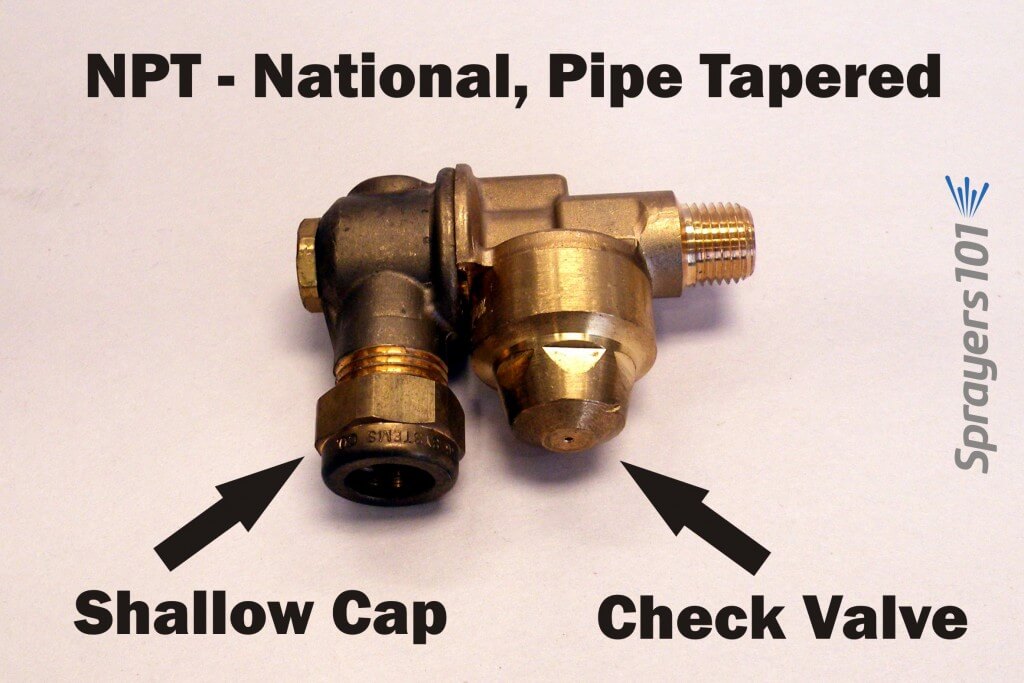

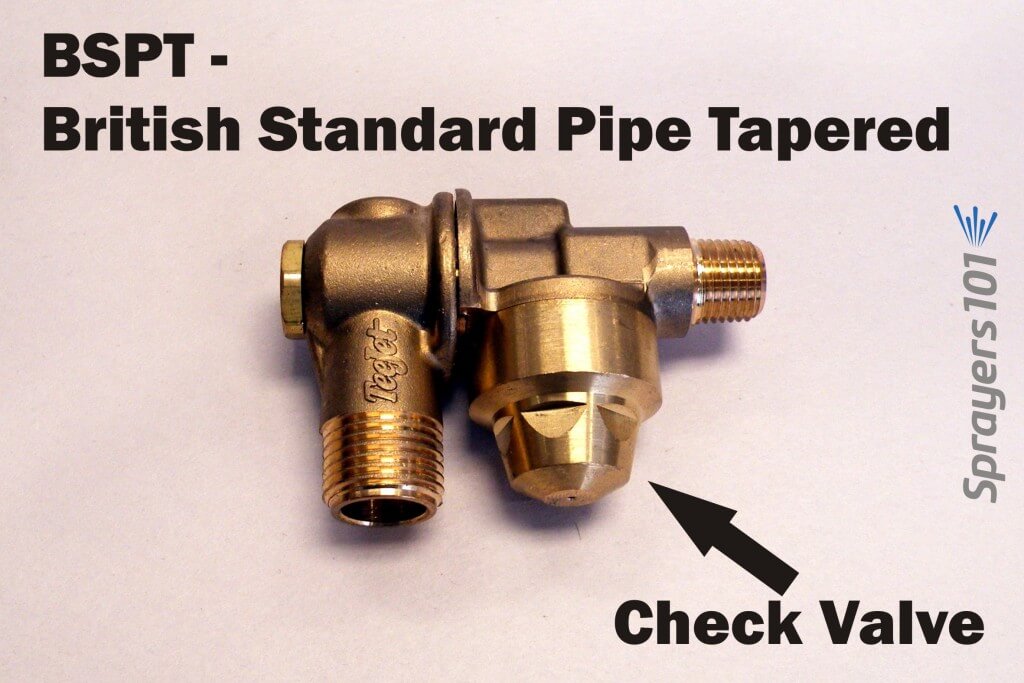

In North America, you will encounter four inlet thread types: NPT, BSPT, NPS and BSPP.

The inlet thread sizes available are 1/4” female, 1/4” male and 3/8” male. 1/4” female is not available on the NPS or BSPP inlet thread types. If you are considering installing new roll-over bodies, know your boom’s thread type. The retrofitted Turbomist below, for example, required bodies with female fittings.

Molded Nozzles

Another reason for installing new bodies is to convert from disc & core combination nozzles to single-piece, molded nozzles. They may not fit existing nozzle bodies. Check the diameter of the body outlet (where the nozzle rests) and the outlet cap (which compresses the nozzle against the body outlet). Your sprayer may currently use an unusual-diameter nozzle, like older FMC disc & whirls or European large-diameter pink ceramic disc & cores. Today’s ISO molded nozzles won’t fit in those bodies, so you’ll need to replace them.

Be aware that unlike disc and core, molded nozzles protrude and may hit the edge of the sprayer duct when rolled over, preventing them from turning freely.

Nozzle Body Caps

Nozzle bodies DO NOT come with the nozzle caps; they are specific to the nozzle type and must be ordered separately. This was an unpleasant surprise the first time I ordered a set of bodies.

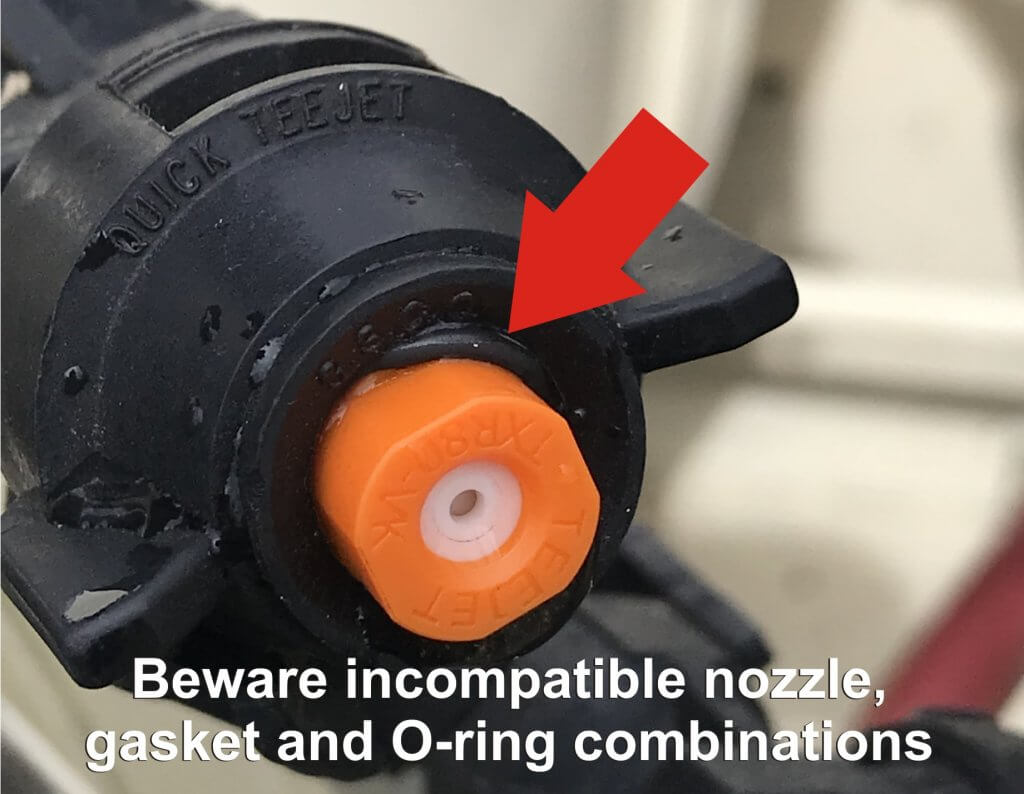

The standard caps are threaded brass hex nut-style but there are also nylon wing-style caps that don’t require a wrench. Beware converting to quarter-turn systems for airblast sprayers. It can work, but nozzles may require additional gaskets and O-rings… and even then are known to leak if the cap diameter is too large (see below):

Be aware, North American nozzle caps might not fit imported European bodies, and European nozzles might not fit North American cap diameters. The LipCo sprayer is one such example.

Regarding the cap depths, sprayer operators must consider the how much “stuff” is between the nozzle body and cap. Gaskets, spacers, O-rings and strainers take up room that may warrant a deeper cap. Perhaps most critical is the nozzle itself. For example, brass disc-core are quite thin, but ceramic are much thicker. They require different cap depths.

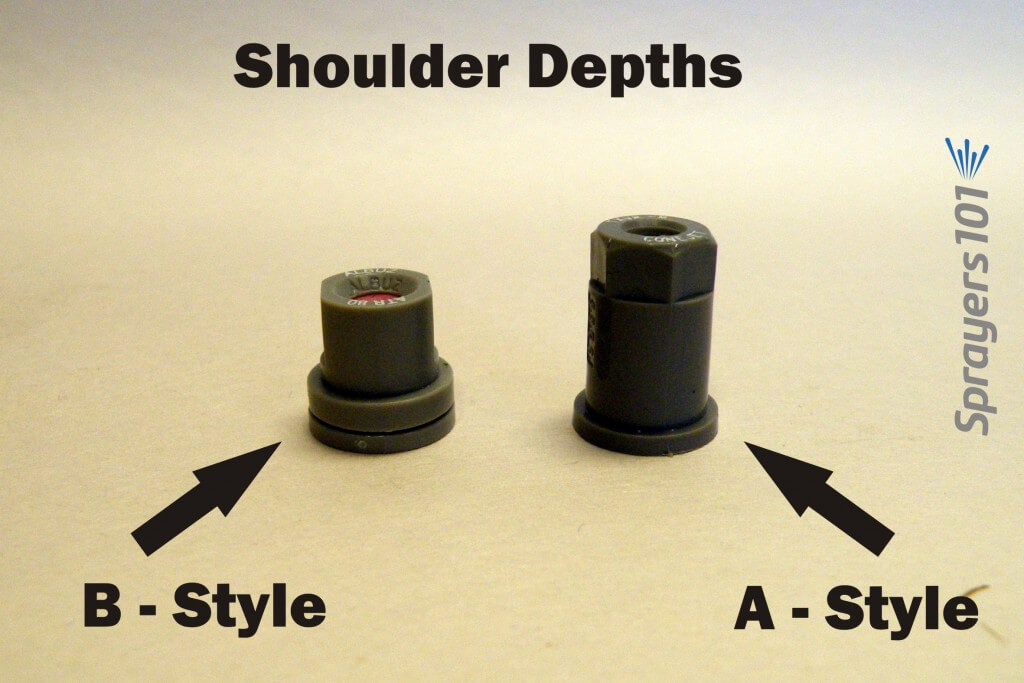

TeeJet’s molded cone nozzles come with an ‘A’ (Thinner) or ‘B’ (Thicker) shoulder. The shoulder is the lip around the nozzle base that is compressed against the nozzle body outlet. The B-shoulder is the ISO standard, and is preferred (see below). Shallow caps may not thread onto a nozzle body using a nozzle with a B-shoulder. Deep caps may bottom-out before compressing a nozzle with an A-shoulder, creating leaks. Be sure to note in the nozzle catalog which caps are recommended for the nozzle.

Nozzle Strainers (aka Filters)

Before we wrap up, here’s one more look-out. As mentioned, the nozzle strainer shoulder takes up some room between nozzle body and cap. It turns out there can be another concern.

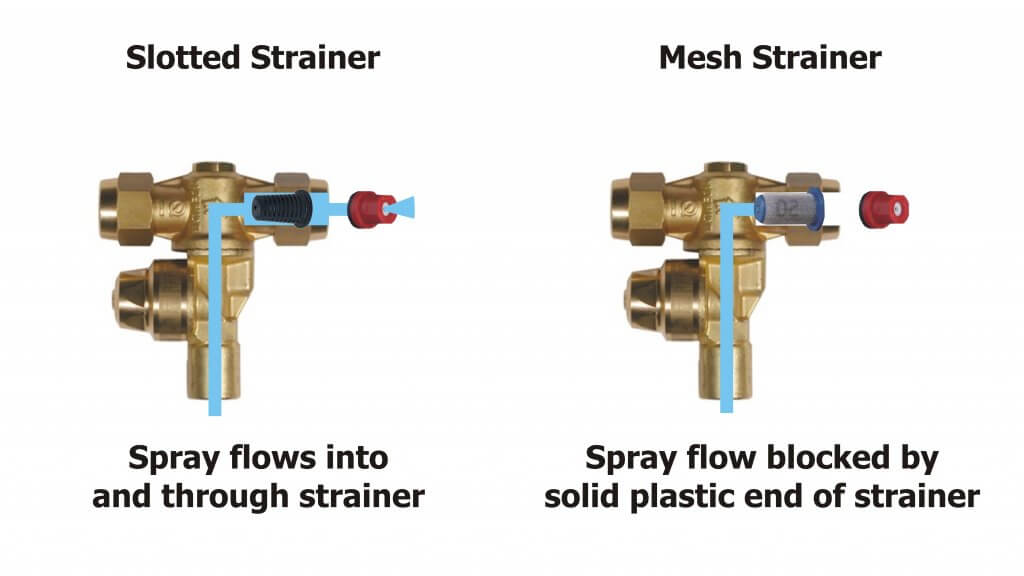

A hop grower contacted me. He had installed new nozzle bodies on his sprayer. He’d taken into account the shoulder depth and the cap depth. So why were his nozzles plugged? And why when he loosened the cap to finger-tight did they spray, but leak?

We tried gaskets, O-rings, different cap depths and new nozzles – but no change. That’s when we noticed one side of the roll-over body had a plastic slotted strainer and the other had newer mesh strainer. The mesh strainer were longer and terminated in a disk of solid plastic. When we swapped the two strainers, we had flow! We realized the longer mesh strainers were being compressed against the orifice in the nozzle body, acting like a cork in a wine bottle.

I prefer slotted over mesh because they are a bit more forgiving with dry formulations and hard water residue, but perhaps more critical is that they aren’t long enough to block the flow.

Take Home Tips

If you are considering installing new nozzle bodies:

- Confirm the male or female fitting and thread type of your boom

- Ensure bodies have check valves

- Ensure roll-overs and check valves clear any obstructions with nozzles in place

- Know the nozzle type you intend to use, and ensure cap diameter is appropriate

- Know whether you will use gaskets, o-rings, spacers and strainers, and confirm the cap depth will accommodate everything.

- Be certain the strainer you choose isn’t so long that it interferes with flow.

- Consider buying a single nozzle body to install as a trial before buying an entire set of replacements.