The introduction of dicamba and 2,4-D tolerance traits in corn and soybeans was accompanied by an unprecedented emphasis on spray drift management by the registrants. Product label statements for 2,4-D choline and the new formulations of dicamba emphasize spray drift control to a greater degree than previous products.

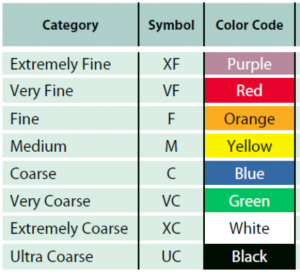

In Canada, labels make prominent reference to the appropriate “spray quality”, a term referring to an internationally standardized droplet size classification (ASABE S572.2). In this standard, the droplet size spectrum produced by a nozzle is communicated using terms such as “Medium”, “Coarse”, “Very Coarse” etc., and used to describe the potential for spray coverage and spray drift. Spray qualities are colour coded for easy recognition.

An example of this label language is shown for Enlist Duo below:

“Droplet Size: Apply as a coarse to extremely coarse spray (ASABE S572 Standard). Use drift reducing nozzle tips in accordance with manufacturer directions that produce a droplet classification of coarse to extremely coarse to significantly reduce the potential for drift.”

Although spray qualities are voluntarily measured and published by most nozzle manufacturers, their appearance on the label makes their use a legal requirement. This is because the Pest Management Regulatory Agency (PMRA) conducts a risk assessment which assumes, in this case, that a Coarse spray quality supports certain calculated buffer zones (15 m in this case) to protect sensitive ecosystems from Enlist Duo damage.

The use of coarser sprays can be used to reduce this buffer zone somewhat, in accordance with an on-line “Site-Specific Buffer Zone Calculator” published by the PMRA.

The challenge for applicators will be to determine the spray quality of their current application method. Here’s a relatively simple three-step process to find out.

Step 1: Identify the nozzles currently on the sprayer.

It seems basic, but it’s surprising how many applicators can not name their spray nozzle. If unsure, closely inspect the nozzle, looking for the manufacturer’s name, the nozzle model, and its flow rate. Most nozzles will have this information printed right on them. Here are pictures of the most common nozzles. Can’t find the info? Have a look at this article for websites with pictures.

Major manufacturers include Hypro (John Deere via private label), Agrotop (marketed by Greenleaf in North America), Hardi, Lechler, TeeJet, Wilger, and Billericay Farm Systems (Air Bubble Jet). Manufacturers produce many models, but most are easily identified by a series of letters and numbers. For example, all nozzles will be offered in several fan angles (80º and 110º are most common), and flow rates (in US gpm).

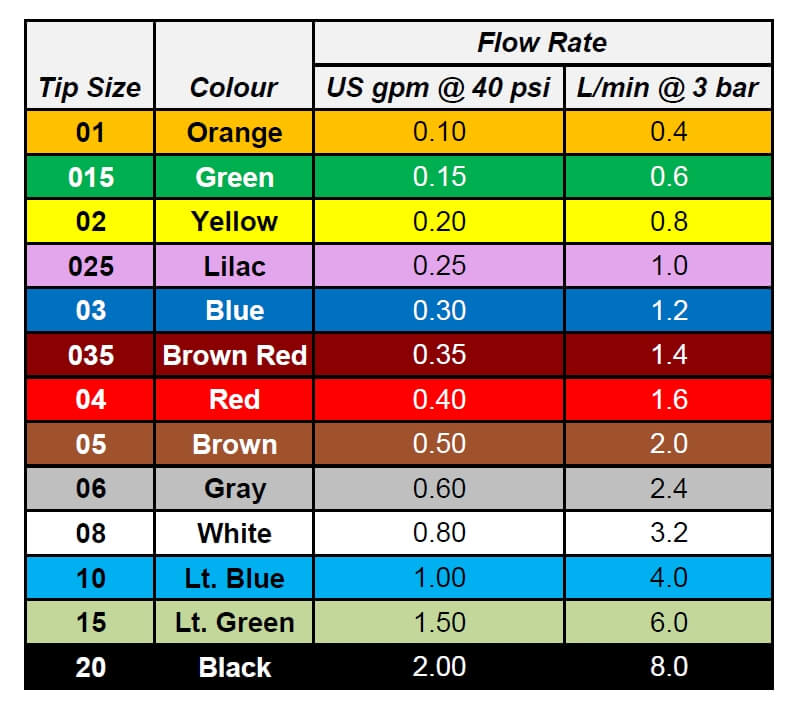

To be more helpful, flow rates are colour coded according to an international standard. This table shows the colours and lists flow in US units in (gpm at 40 psi) and metric (L/min at 3 bar).

The combination of series of letters or numbers shown on nozzles follows a relatively consistent pattern: Fan angle and flow rate arranged as 11003 or 03-110. In this case, the nozzle produces a 110 degree fan and has a flow rate of 0.3 US gpm. The use of US gpm at 40 psi to designate flow rate is an international standard.

The nozzle model is frequently inserted into this stamp, and is manufacturer specific. For example, TeeJet may include “AIXR” in its stamp, and Agrotop may include “TDXL”. Hardi’s MiniDrift is abbreviated MD. Some nozzles may not list their fan angle. Others (Air Bubble Jet) are blank, creating a mystic aura of superiority. Others leave the information printed on the nozzle cap.

A bit of experience is very helpful, especially with John Deere nozzles, where the nomenclature inexplicably eliminates the first digit of the 110 or 120 degree fan angle. So the JD 11004 is labelled “1004”. That’s a bit like saying “my truck sas a 50 engine”, when you mean it has a 350. How’s a city person supposed to know you don’t mean the trusty old 250 straight 6?

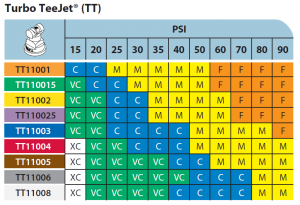

Step 2: Obtain spray quality information on the nozzle.

Most manufacturers publish the recommended pressure range and the spray quality of their nozzles. This information can be found in their product catalogues, or on their websites, or in smartphone apps.

Although the designation of Spray Quality is governed by an international standard that is designed to standardize droplet sizing among various labs, we do see some variation in results. Part of this is due to the continued evolution of the standard, requiring manufacturers to re-do some tests, or at least re-analyze their data. For example, ASABE S572.3 was released in conjunction with ISO25358 which changed the boundaries for the coarser sprays. These changes are beginning to be seen in the newer catalogues.

Another problem is that testing is done with plain water. It is well known that the use of certain formulations or adjuvants can affect spray quality. Currently, the standard does not address these effects, and data should be used with some caution.

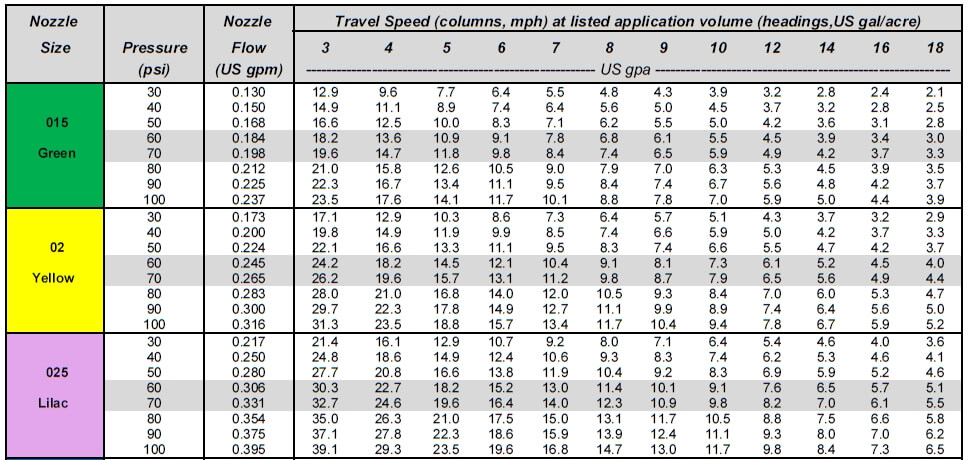

Step 3: Identify the expected pressure for a given travel speed and water volume.

The same catalogues or websites that publish spray quality also produce charts that list the expected spray pressures at various travel speeds and water volumes.

Becoming familiar with using these charts enables the applicator to predict the spray pressure the nozzle will be operating at. For example, if an applicator intends to apply 10 gpa using a yellow (02) nozzle, this table shows the following: The nozzle will be operating at 30 psi at 5 mph, at 40 psi at 6 mph, at 60 psi at 7 mph, at 70 psi at 8 mph, and at 90 psi at 9 mph. The applicator should know the nozzle’s spray quality at each of those pressures.

Nozzle sizing follows a slightly different procedure for Pulse-Width-Modulation (PWM) systems, requiring the nozzle to be over-sized about 30% or so. Since the majority of new sprayer sales now include PWM, we’ve prepared a special article just for this system here.

Travel speed and/or spray volume should be adjusted to ensure the sprayer operates at a pressure which creates the desired spray quality. In other words, the pressure gauge should be used as a speedometer. If the nozzle model or size doesn’t produce the desired results, the applicator should consider changing nozzles. Once the right combination of factors has been determined, the spray pressures that created the label-required spray quality should be noted. From that point, the applicator can choose travel speeds that maintain the necessary pressure range.

Summary

It is up to applicators and industry representatives to ensure that herbicide products are applied according to label requirements. We expect significant scrutiny on spray drift from new products and need to ensure that proper application methods are used at all times. It’s important that everyone understands just how to do it.

Dr. Scott Bretthauer (U. Illinois) gives a nice summary in this video by Precision Labs: