Despite the abundance of information available on spray drift, we continue to see widespread incidents of damage to a variety of crops every year. Do applicators just not care or are they missing some vital information when making decisions to spray? I believe it is the latter.

What is the problem?

In my experience, the vast majority of spray drift cases (probably 90% or more) are the result of ‘inversion drift’. That means the drift has not come from an adjacent sprayed area, it has come from one or more sources that are some distance from the site of damage. The distance between the sprayed site and the location of the damage may vary dramatically, from a few kilometres to tens of kilometres.

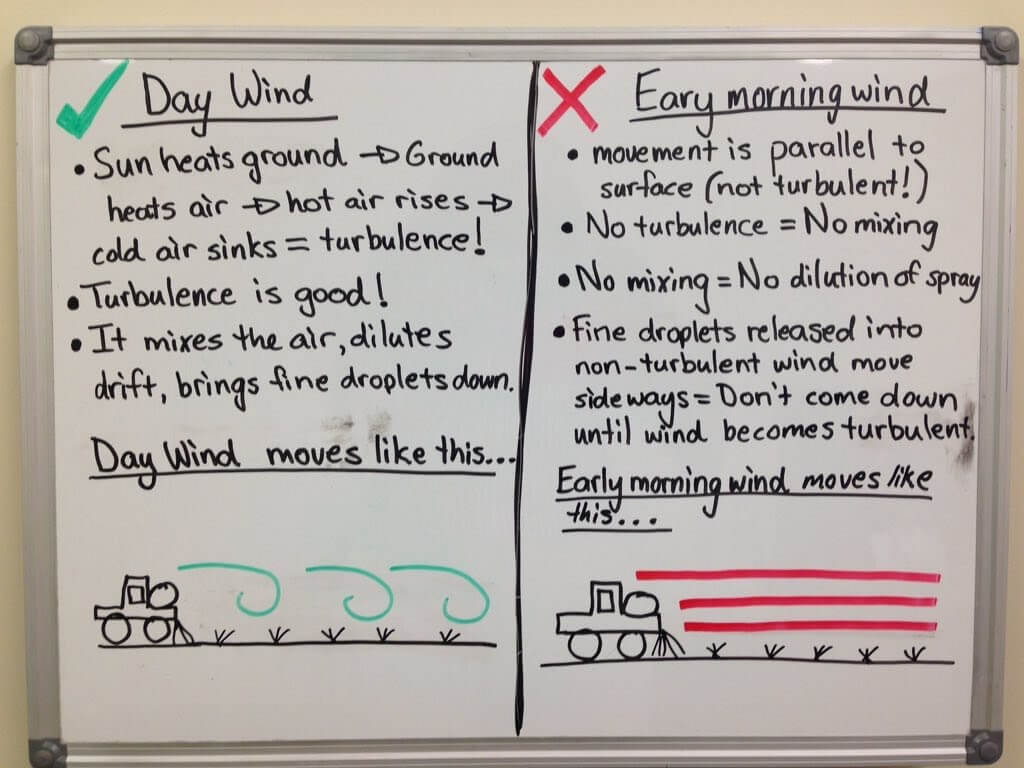

Why is there so much inversion drift when labels specifically prohibit use of the products under surface temperature inversions? Many may argue that it is a blatant disregard of the label by a few applicators (translation = cowboy operators). I do not agree this is the main problem. While I can confirm the existence of ‘cowboy operators’, thankfully they are limited in number. I believe the problem is a lack of understanding about how to tell when there is an inversion and particularly not knowing how ‘day wind’ moves differently to ‘inversion wind’. I continue to see good farmers/applicators doing what they believe to be the right thing but it is not. These are people very concerned about minimizing spray drift; they honestly do not think they are doing anything wrong.

What is ‘day wind’?

After sunrise, the sun begins to heat the ground, the warm ground then heats the air close to the surface, and this air then rises. As that warm air rises, cold air from above sinks down to replace it. The ground then warms this cold air and it rises. This cycling of warm air rising and cold air sinking creates turbulence and then wind. This is a good thing; turbulent wind movement is much safer for spraying. ‘Day wind’ has a turbulent motion and is much more likely to pull any fine droplets to the ground within a reasonable distance. During the day, we can predict which direction and how far our fine droplets will travel.

What is ‘inversion wind’?

As the sun sets, the ground begins to cool quickly and this in turn cools the air next to the ground. As we all know, cold air does not rise and warm air does not sink. This means there is a layer of cold air trapped close to the surface and a layer of warm air above it. The result is no turbulent movement or mixing of the air. The air may become quite still and this is often observed around sunset when the daytime wind ceases or drops off. What happens next is where the real danger occurs for spraying.

As the night progresses and the ground cools more, the cool air close to the surface becomes colder and therefore more dense, particularly from midnight onwards. This cold dense air then begins to move across the landscape, often down slope and in very unpredictable directions. Remember this air is not turbulent, there is no mixing, it has layers of air, something like layers in plywood, and it flows parallel to the ground. Any fine droplets released into these layers of cold non-turbulent air will simply move sideways across the surface until the sun rises and heats the ground again. This is when the fine droplets are released from the layers and they come to ground, often in the lower parts of the catchment and a long way from the site of application. It is impossible to predict what direction this ‘inversion wind’ will go. For this reason, spraying in this type of wind is extremely high risk for spray drift.

Key indicators that and inversion is unlikely

- We should always expect that a surface temperature inversion has formed at sunset and will persist until sometime after sunrise unless we have one or more of the following: continuous overcast weather, with low and heavy cloud;

- continuous rain;

- wind speed remains consistently above 11km/h for the whole time between sunset and sunrise;

- and after a clear night, cumulus clouds begin to form.

Inversion wind movement – practical demonstration video

Wind is a key factor in any spray application. The problem is that not all wind is the same. To reduce the incidence of spray drift, it is critical that spray applicators understand how wind moves, particularly during a surface temperature inversion. This video uses smoke flares to visually demonstrate the air movement under inversion conditions.

Here’s what we’re looking for: moderate wind with consistent direction that disperses spray and drives it to ground.

Conclusion

Many factors affect the potential for spray to drift but the main ones are; the weather conditions at the time of application, nozzle selection, products/tank mix used, actual spray quality achieved, speed of rig, and boom height. The common denominator is that all of these things are within the control of the spray operator.

Spraying under inversion conditions is extremely high risk and prohibited on many product labels, that means it is illegal. If you are serious about preventing drift, then you must learn how to identify when an inversion is likely to be present and more importantly when it has broken.

All agricultural chemicals have the potential to drift; it is how we use them that increases or decreases that potential. Therefore, the problem is a human one, not a chemical one. There is a suite of information available but if you are still unsure or need any assistance, please seek advice from an expert. Maintaining long-term access to key products depends on us reducing spray drift.