This article was co-written with Jennifer Llewellyn, OMAFRA Nursery Crop Specialist

Many horticultural commodities, such as turfgrass and nursery crops, include the application of live nematodes as part of their annual IPM program. In 2013 we performed preliminary research into the claim that a grower’s nematode applications were becoming less effective. In the course of the investigation it was discovered that the nematode concentration (i.e. dose) sampled from the spray nozzle was diminishing over the course of the application.

After eliminating potential sinks in the sprayer’s plumbing (e.g. filters, strainers, etc.) it was hypothesized that the nematodes were adhering to the interior of the poly tank. If this was the case, the concentration would drop as the level of spray mix dropped. To test the hypothesis, we installed a tank-rinse nozzle to sparge the inner walls of the tank throughout the application and to re-suspend any stranded nematodes.

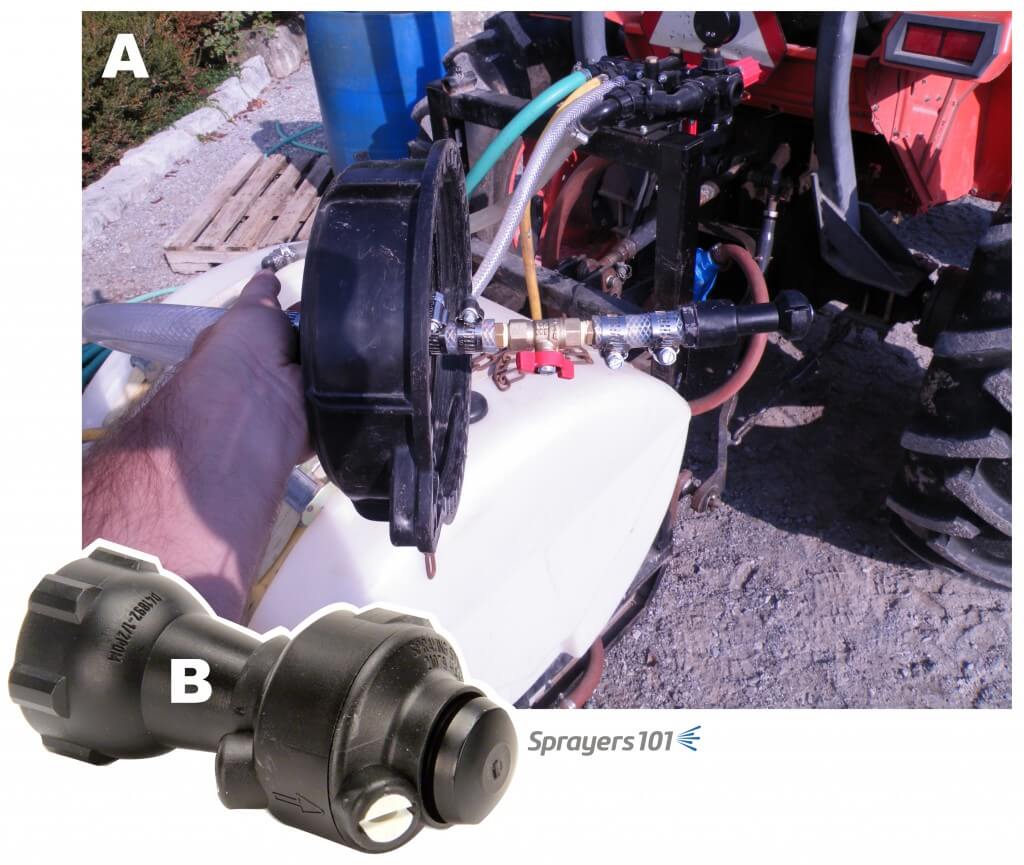

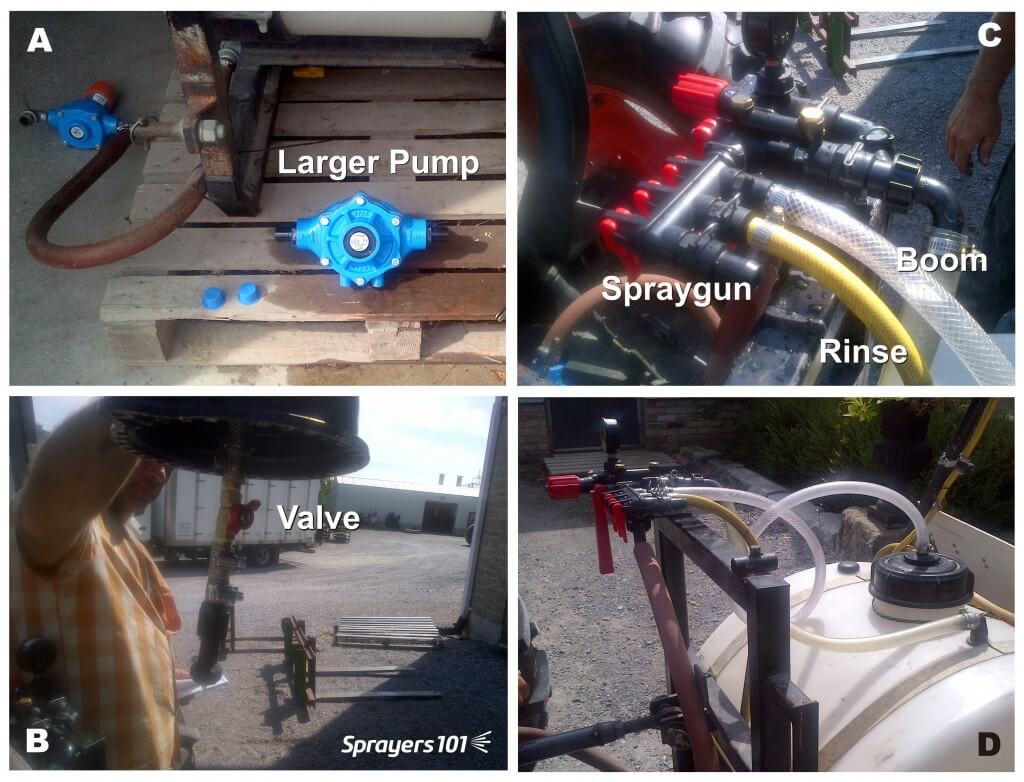

A high capacity roller pump (Pentair series 1700C) was installed to operate the tank-rinse nozzle (Pentair Proclean Tankwash) during spraying. It was installed through a bulkhead fitting in the tank fill lid. During testing it was discovered that the tank-rinse nozzle shunted too much flow and pressure to maintain flow to the spray gun. A valve was installed behind the tank-rinse nozzle to restrict flow to the point where it gently rinsed the inner walls of the tank, restoring flow and pressure to the spray gun.

(C) Counting nematodes. (D) Undiluted, healthy nematodes in a stock solution via microscope ocular.

The 200 L tank was inoculated with a stock solution containing 25 million nematodes (125 nematodes / ml). 20 L of the spray solution was sprayed into a bucket every 10 minutes, whereupon 1 L of spray solution was immediately removed and 1 ml volumes were sub-sampled for counting.

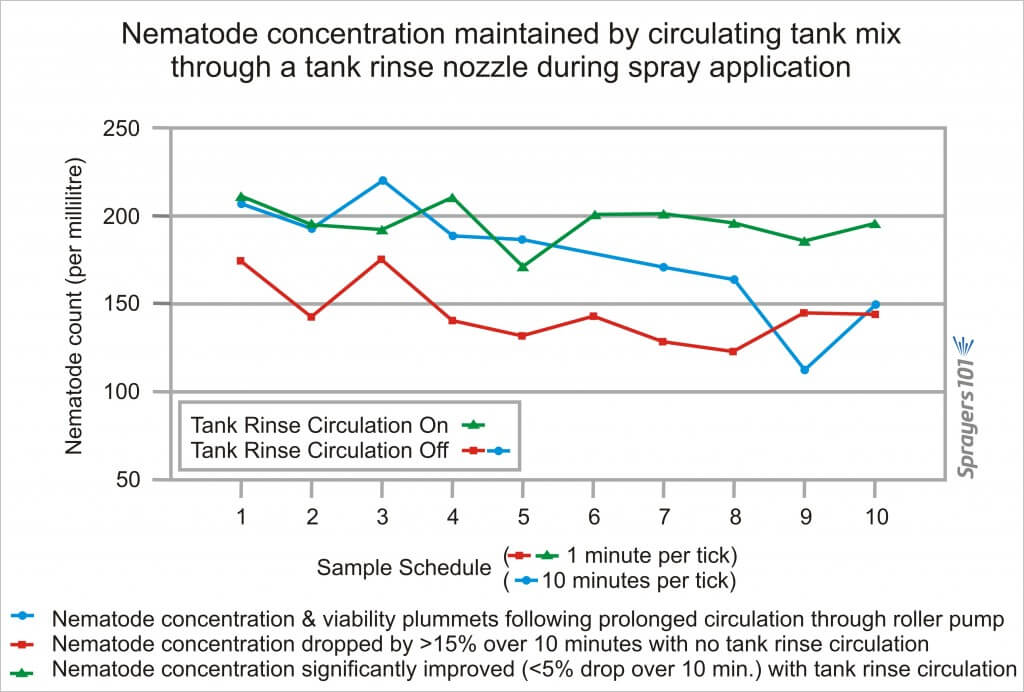

In the first trial, nematode counts continued over a period of 2 hours and viability dropped by ~40%. It was assumed the damage was caused by prolonged circulation through the roller pump. In subsequent trials, the sampling duration reduced to 10 minutes (more realistically reflecting the time it took the grower to apply 200 L in the field). The tank was rinsed and re-inoculated for each trial. 1 ml samples were drawn from the spray gun, which operated continuously, with and without the tank rinse nozzle in operation.

Univariate analysis confirmed data normality and a GLM procedure was conducted for analysis of variance. Results indicate that nematode concentration dropped by ~15% without tank-rinse with minimal nematode damage observed. With the tank-rinse nozzle engaged, the concentration still declined slightly, but significantly less (<5%) (see graph below).

The results suggest that a tank-rinse system that sparges the tank walls preserves nematode concentration throughout an application and may lead to more efficacious applications.

Horticultural Crops Ontario, Ground Covers Unlimited, Pentair (Hypro) and Nemapro are gratefully acknowledged for making this research possible.