When an extension specialist, equipment retailer or consultant is asked to calibrate an airblast sprayer, they would be well advised to calibrate the sprayer operator as well.

Consider this: you and the operator are each investing three hours (average) to optimize the sprayer for a specific set of circumstances: the crop dimensions, density, and the weather conditions at the time of calibration. Depending on the reason for the application, you may even account for the product(s) mode of action and the pest location. This means that once you leave, the circumstances will change and the benefits of your efforts will quickly diminish.

Calibrations, like milk, have an expiry date.

There are three possible outcomes from a single, stand-alone calibration:

- The operator manages efficacious applications throughout the season because the variability in weather, crop and pest isn’t significant. This is generally not the case.

- Not recognizing that sprayer settings need constant adjustments (or being unable to make the changes) the operator experiences only modest results and decides calibration isn’t worthwhile.

- The operator experiences failures and lays the fault with you (as the last person the touch the sprayer) and/or the agrichemical rep that sold the chemical. Few sprayer operators blame timing or spray coverage.

The solution lies in the proverb “Give a man a fish and you feed him for a day; teach a man to fish and you feed him for a lifetime.” It is the sprayer calibrator’s responsibility to involve the sprayer operator and ensure they understand what is being done, why it is being done, and how to do it when you leave. Otherwise, expect to calibrate that sprayer again… soon.

Personally, I have had the most success educating and empowering spray operators to make their own seasonal adjustments based on a formulaic approach. Depending what you are trying to accomplish, you may not need all of the following steps, or you may perform some on your own and others as part of the education:

1) You could be working one-on-one, or you may be presenting to a large group. When it’s the later, I like to arrive the day before to meet the host or owner of the sprayer(s). You can scope out the operation and triage the equipment so you know what parts you might need the next day. It also helps to see the space you will be working in.

2) Perform a pre-calibration inspection of the equipment with the sprayer operator. They know their equipment and can tell you about usage, history and maintenance. It also opens a dialogue between you and helps the operator to relax. Remember: from their perspective they may feel they are being judged and they will take criticisms and corrections personally. Do your best to reassure them that you are trying to make a good thing better – not to correct failings.

3) If you’re working at a large operation, educate the manager (decision maker) and the operators (drivers) at the same time. If you teach the manager, they might not effectively communicate the lessons to their operators. Likewise, if you teach the operators, they may not be able to convince the manager to let them spend money, or time, on making changes to the sprayer program. Get everyone on the same page, at the same time.

4) With the operator, perform a basic maintenance check. Specifically, confirm sprayer ground speed, evaluate pressure gauge accuracy and evaluate nozzles. Explain what you are doing, and ask the operator questions. This is where you learn about their attitude. Are they open-minded about changing how they do things? How has their efficacy been in the past? Will they spring for new parts? Do they need convincing that this process must be repeated regularly?

5) With the sprayer in the crop, have the operator tie wind-indicator ribbons in the canopy (or better, use lengths pre-tied to springback clips). Explain what they are doing and why. Tell them these ribbons should be monitored, maintained and replaced season-long.

Here’s a tip: If you are working with a large audience, keeping them focused is critical. Growers will take the opportunity to catch up with each other while you are occupied with the sprayer. They are also inclined to wander away to answer cell phones. If they are not focused, you are on a service call and are not really educating. If you feel you are losing control, single out the ringleaders or wayward students and give them jobs, such as holding tools, or placing/removing water sensitive papers. When they have a responsibility, they pay closer attention.

6) Discuss where water-sensitive papers should go, and how they should face. Give the operator a latex glove and after you write on the back of each card (position and trial number) have them clip them in place. Tell them how much they cost, where to buy them and the benefits of using them regularly.

7) Have the operator spray the target crop using their typical set-up (i.e. ground speed, pressure, rate, air settings, etc.) Have attendees and the operator watch the ribbons as the sprayer passes. Spray from one side with both booms on and then stop to discuss results. Then spray from the other side and explore the cumulative impact.

8) The operator will be very surprised to learn they have drenched or missed the papers. They may or may not be surprised to have seen the ribbons stood straight out (indicating too much air). If you like, you can even set up papers in the next alley (or alleys) to show how much spray blew through the target. When the papers are dry enough, collect them and store them somewhere safe for later comparison. They tend to blow away, so stick them to a whiteboard with two-sided tape, or clip them there with paperclips. Explain that they can (potentially) save a lot of money and lost fill-time by improving their efficiency. Get them on-board for the big change to come.

9) Optimize sprayer ground speed, air direction (i.e. deflectors) and air speed/volume (i.e. fan speed). Then re-nozzle the sprayer using brass disc and core tips to reduce output in areas that were drenched or increase output in areas of sparse coverage. Quite often, I turn off the lowest (and sometimes, highest) nozzle positions. A piece of water-sensitive paper at the top and bottom of the canopy will confirm the wisdom in this. Label a new set of papers and have the growers position them in the same locations. Spray again. This entire process should take about 1/2 an hour and is described in detail in the Airblast101 handbook.

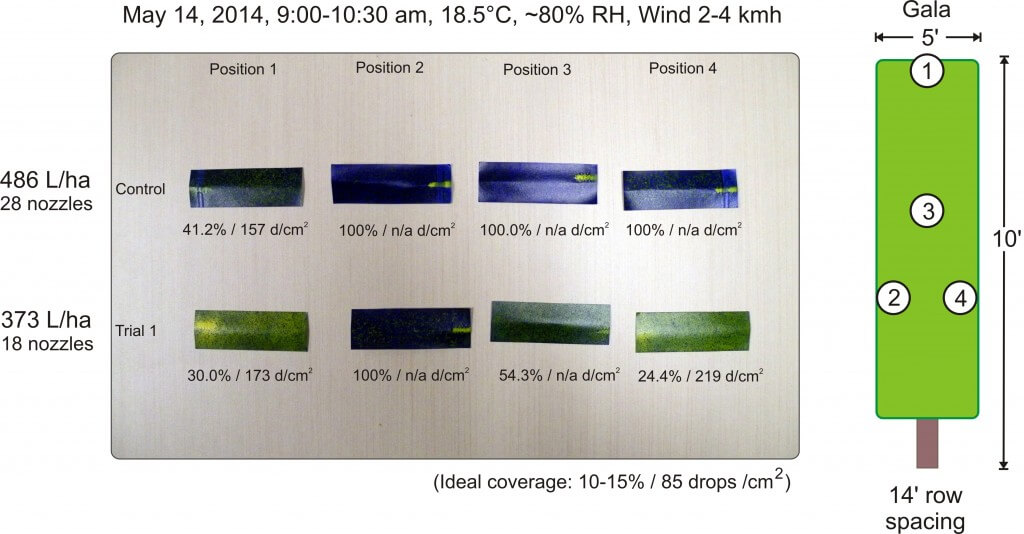

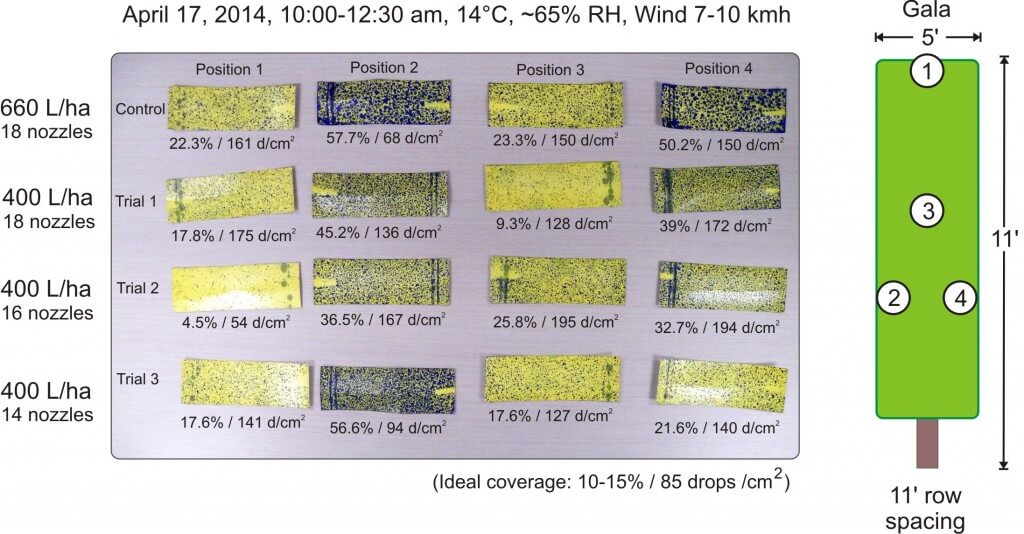

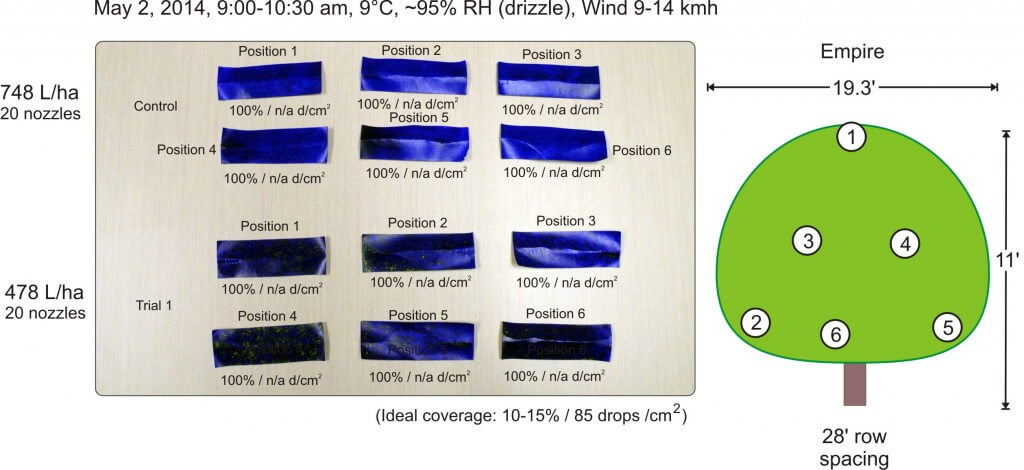

10) The goal is 85 medium droplets per square centimetre and 10-15% coverage on 80% of the target surfaces for most insecticides and fungicides. If there are still drenches or misses, or if you’ve gone too far in a few positions, correct them and try once more. This is iterative. Make sure the sprayer operator will not be spraying in particularly hot or windy conditions, or your calibration at the top of the target can be compromised. Once you are both satisfied, work out the new sprayer output per area (e.g. US gpa or L/ha). You will have to discuss whether the operator plans to concentrate the tank mix to maintain the labelled “per area” rate (not recommended by me) or will continue to mix the tank as always and simply drive further on it (recommended by me). The later is called “Crop-Adapted Spraying“. Don’t push because it’s their livelihood, and therefore their choice.

11) The final step relies on how well you’ve earned the sprayer operator’s trust throughout this process. Once you have an output and spray distribution that you are both happy with, the operator should invest in molded ceramic tips that emit similar rates to replace the brass disc-core. Then, they must be willing to repeat the process on any crops that are significantly different to ensure they have the right settings. Sometimes only modest changes are required between blocks. Perhaps they will dedicate certain sprayers to certain blocks to reduce the number of changes required. In either case, they will have to revisit these settings as the season progresses to compensate for denser and/or larger canopies.

A few examples

The following figures illustrate three airblast calibrations in Ontario apple orchards from spring 2014. Some required one attempt; others required a few trial settings before we achieved reasonable coverage. In all three cases, the sprayer operators reduced per-area rates, bought new nozzles and planned to buy water-sensitive paper. Further, they indicated they would continue to monitor ribbons (as long as they could be seen) and would review coverage after petal-fall.

Conclusion

So, the next time you calibrate an airblast sprayer, be sure to teach the sprayer operator (and audience) what you are doing and why. Involve and engage them. Answer their questions. Encourage them to perform the same calibration for each significantly different block and make mid-season changes. With luck they will only call back to report success and savings, and not to condemn your efforts, or worse: to ask you to re-calibrate their sprayer!