Dear reader: This article is intended to provide basic information on how electrostatic sprayers work in an agricultural setting. The author does not sell or manufacture sprayers. If your interest is related to spraying disinfectant in private or commercial settings, please contact retailers or manufacturers of electrostatic sprayers.

Electrostatic nozzles have been tested in agriculture since the late 1970’s. Predominantly used in aerial applications, they are sometimes employed on airblast sprayers in orchard and berry operations, and on horizontal booms in vegetable crops. To a lesser extent, they are even mounted on wands for low acreage applications.

Claims

Independent research, manufacturer claims and user testimonials are intriguing:

- Improved coverage uniformity (i.e. underleaf coverage, panoramic stem coverage and canopy penetration).

- Improved retention (>50% better than conventional) and/or potential savings of 50% spray mix.

- Reduction in losses to soil.

- Improved efficacy with both insect and disease control.

So it begs the question: “Why doesn’t everyone have an electrostatic sprayer?” We performed a study in carrot in Ontario’s Holland Marsh to explore some of the claims and to get a first-hand experience with the technology. That article might help answer the question. But first, read this article which explores the basic principles behind how electrostatic applications work.

Charging the Droplet

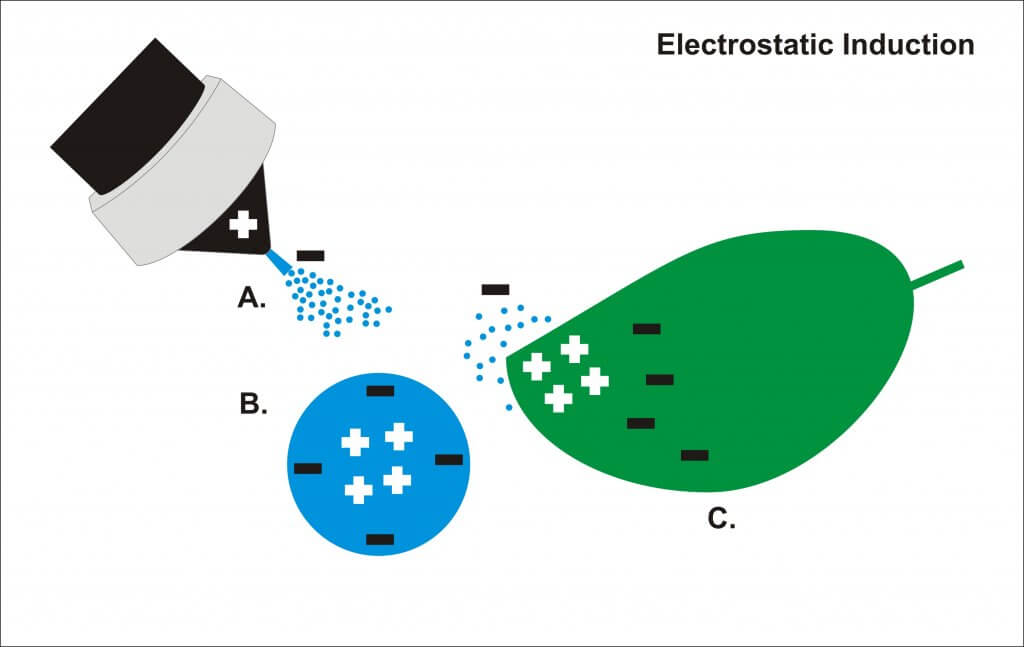

Spray is charged by a high voltage supercharger. Commonly, the charge is induced by an electrode positioned close to the atomizing spray plume as droplets begin to form. This is referred to as coronal discharge. An intense electric field imparts a positive or negative charge depending on the polarity of the DC power used. Think of it as high-voltage static electricity.

Sometimes the spray is atomized by a hydraulic nozzle (e.g. a hollow cone) and sometimes using an air-shear nozzle. The latter has the added advantage of blowing droplets away from the electrode and projecting them into the canopy.

Let’s consider a negatively-charged droplet (see diagram below). The droplet becomes polarized when it passes through the electric field. The field attracts electrons to the droplet surface and repels positrons towards the centre. The droplet now has its own field that electrically motivates it to land on neutral objects. As they approach such an object, the negative charge on the droplet surface repels mobile electrons on the surface of the target, which redistribute, creating a relative positive charge on the surface and attract the droplet.

Another style of electrostatic technology employs a highly charged plate along the air outlet of the sprayer, generally attached just inside the duct. The clearance between the droplets and the plates is quite large in relation to that in a twin-fluid atomizer, coil-type charging system.

Droplet Size

Droplet size is a critical factor. Droplets must be large enough to resist evaporation and drift but small enough that the charge can change their trajectory when it comes close to a target (I.e., the Charge-to-Mass Ratio). Most electrostatic nozzles produce ~50 µm droplets, categorized in agriculture as Very Fine. For comparison, a human hair ranges from 20 to 180 µm. Fog is about 5 µm. Such a small droplet means that the distance between nozzle and canopy is a determining factor for the spray depositing, or drifting.

Droplet Behaviour

Many forces influence droplet behaviour (E.g., inertia, wind, gravity, etc.). Very Fine droplets have a low terminal velocity causing them to fall slowly (~40 seconds to fall 3 m). This makes them highly drift-prone. However, simulations have shown that a charged droplet released close to a grounded target would be “pulled” faster than an uncharged droplet. Further, their trajectories would be less affected by air movement and they have the potential to move upwards against gravity towards the underside of a leaf.

Of course the droplets must reach the canopy before any of these potential advantages can be realized. Even with air-assist to project the spray into the canopy, it has been shown that the droplet must be within two centimetres of the target before attraction improves deposition. There are many physical phenomena that influence this process:

The Faraday Cage Effect can occur when spraying dense canopies. The spray deposits on the first grounded object it encounters. This is the outer surfaces of the canopy and the spray can be prevented from moving deeper into dense canopies. Regarding arable crops, there is often a naturally occurring negative charge on the earth’s surface that repels negatively charged spray. This may be why studies often report reduced loss to soil.

The Corona Effect is a very complicated relationship between the shape, density and spacing of the crop and it’s influence on charged spray. Research has shown that deposition is better for rounded targets than pointed. The gaseous exchange of charges between leaf tips and spray can neutralize or even repel droplets. This may be why electrostatic demonstrations so often include fruit or spheres.

The Expansion Cloud Effect (or cooler, the “Space Cloud” Effect) describes how charged droplets are repelled by objects with a like charge. Coulomb’s Law describes how objects with an opposite charge attract, but it also says objects with a like charge repel. Since the droplets all have the same charge, they repel each other. While this causes the plume to expand into the canopy and helps to distribute the droplets to give uniform coverage, it also causes droplets to expand upwards away from the crop, making them susceptible to drift.

Observations

The opportunity for reduced pesticide use is appealing and it may entice consumers to consider the electrostatic sprayer as a more environmentally-conscious choice. However, we have found very few studies relating to drift, and opinions are mixed whether electrostatic applications are any more drift-prone than conventional applications.

Considered collectively, electrostatic applications seem to perform well in controlled conditions, but the complications arising from variability in a natural environment coupled with the cost of equipment has slowed adoption. The current rules for practical adoption are poorly defined. More fulsome drift studies are required and coverage uniformity and canopy penetration (particularly from ground rig systems) must be consistent in real world settings.

Nevertheless, electrostatic applications have a lot of “potential”.