This article was co-developed with Mark Ledebuhr of Application Insight, LLC.

Air handling systems

Air handling systems can be specialists or generalists; some are designed to do one thing very well while others are more adaptable but not as precise. Fan type plays a big role in determining a sprayer’s abilities. Their native characteristics make them better suited to certain scenarios.

This may seem contradictory, but we are not saying that the fan alone defines or limits the entire sprayer. Fans operate within a larger, engineered air handling system. Also, the operator has control over how that sprayer is configured and used. This means it is equally important to consider how the air exits the sprayer – not just the fan type that generated it.

Fan types

- Radial fans: Radial fans produce high volumes of moderately turbulent air, and relatively low static pressures. They are often associated with fixed vanes and straighteners inside the fan housing to reduce initial turbulence.

- Turbines: Turbines may look like radial fans but they’re designed to spin faster and they have blades designed to compress air. They are used in sprayers that have ducts, towers, cannons, or other more complex volutes.

- Straight-through axial fans: These fans produce high volumes of the most turbulent air. With their comparatively short throw and wide air wash, they should be positioned close to the target.

- Tangential (aka Cross-flow) fans: Tangentials produce the most laminar air, forming a very high volume, low velocity jet sometimes called a “curtain” or “knife”. They have a comparatively long throw and rely on the canopy to induce turbulence.

- Centrifugal (aka Squirrel cage) fans: Centrifugal fans have a side-discharge arrangement that turns air 90 degrees. They can produce high pressures and are nearly always paired with an air-shaping volute.

We are proposing defining air-assist sprayers for perennial crops according to their air handling systems. Ultimately, the defining characteristic of each design is the net vector of the air they generate. We have provided silhouettes for clarity, but these generic designs are not intended to imply a manufacturer.

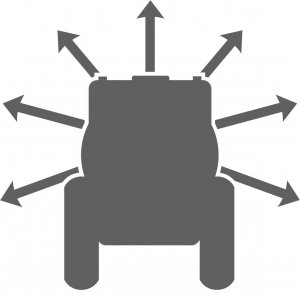

Low profile radial

The oldest and perhaps most recognizable air handling design, the Low Profile Radial (LPR) sprayer generates air in a radial pattern from one or more axial fans or a volute connected to some other fan style. This is the classic airblast sprayer.

Defining characteristics:

- Wide range of adjustable air energies from virtually zero to high.

- Minor adjustability of air vectors via deflectors and moveable outlets.

- Net air movement is lateral and upward.

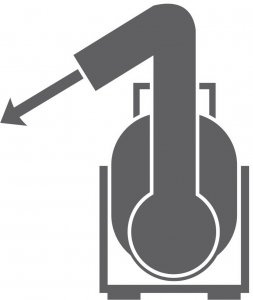

Cannon

The Cannon (CN) sprayer generates and channels air through a single volute and delivers the spray as a compact, point-source jet.

Defining characteristics:

- High air energy characterized by high velocity and low volume.

- Extensive adjustability of air vector via a vertical duct with positional outlet and deflector(s).

- Usually a single-sided sprayer used to spray over and through multiple rows.

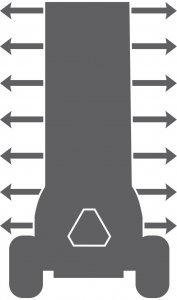

Fixed tower

The Fixed Tower (FT) sprayer generates air from one or more axial fans, multiple straight-through radial or tangential fans. It may employ flexible tubes, tapered bags or solid ducts to redirect air laterally from a fixed central tower. It may feature additional flexible ducts or adjustable deflectors at the top of the tower to spray over and beyond the adjacent rows.

Defining characteristics:

- Wide range of adjustable air energies from virtually zero to high.

- Minor adjustability of air vectors via deflectors and moveable outlets.

- Net air movement is lateral compared to LPR sprayers.

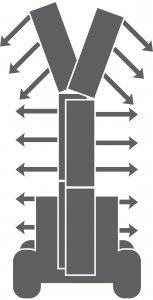

Targeting tower

Similar to the FT, the Targeting Tower (TT) sprayer can focus air vectors with a wider range of adjustability, shaping the lateral air output more precisely to the canopy. TT generates air from one or more radial fans or multiple tangential or straight-through axial fans. It may employ flexible tubes or solid ducts to redirect air generally laterally.

Defining characteristics:

- Medium to high air energy.

- Moderate to high adjustability of air vectors. Airflow can be subdivided into individually-adjustable sections.

- When the tower exceeds canopy height, net air movement is lateral to slightly downward.

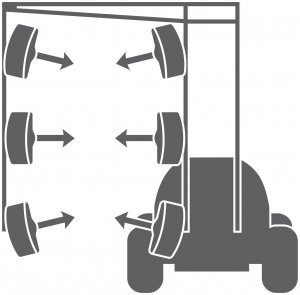

Wrap-around

The Wrap-Around (WA) sprayer surrounds the target rows with air sources. This creates multiple converging and/or opposing airflows within the row.

Defining characteristics:

- Straight-through axial fan systems are either electric or hydraulic with a wide range of air energies.

- Low to high adjustability of air vector via deflectors, moveable air outlets, or fan position adjustments. May also have an adjustable frame.

- Net air movement is ideally neutral to slightly downward.

Summary

In adopting this system of classification, we believe the process of optimizing sprayer configuration and calibration can be made less complicated. A universal language facilitates clear communication between growers, industry and consultants/specialists.

We acknowledge that there may be rare sprayers that don’t fit these categories. There are commercial examples of air-assist sprayers that combine features from these air-handling designs (e.g. hybrids of LPR and FT designs)… but let’s keep things simple.