Agricultural products are formulated to be as emulsifiable as possible, but many do not mix well in water. They contain elements that do not dissolve (e.g. wettable powders), or they may be petroleum distillates (e.g. emulsifiable concentrates). Other products are heavier than water and form precipitates (e.g. fertilizers and powdered metals like copper). Consequently, good agitation is very important.

Effective agitation requires water to “sweep” the bottom of the tank so that any precipitated material is picked up and re-mixed. Turbulence is often not enough. If there is too little agitation, the pesticide will be applied unevenly and not always at the required rate. If there is too much agitation, the pesticide may foam (which can be controlled using anti-foamers) or cause an invert emulsion (a gel). There are two types of airblast sprayer agitation: Mechanical and Hydraulic (learn about pros and cons here).

Mechanical Agitation

Mechanical Agitation is produced by paddles that are attached to a shaft mounted near the bottom of the spray tank. While effective, this system cannot always sweep the very bottom of the tank, so there is always some material that precipitates out of reach. Are your nozzles and screens plugging frequently, and is there “sludge” left at the bottom of the tank after spraying? You have an agitation issue.

Hydraulic Agitation

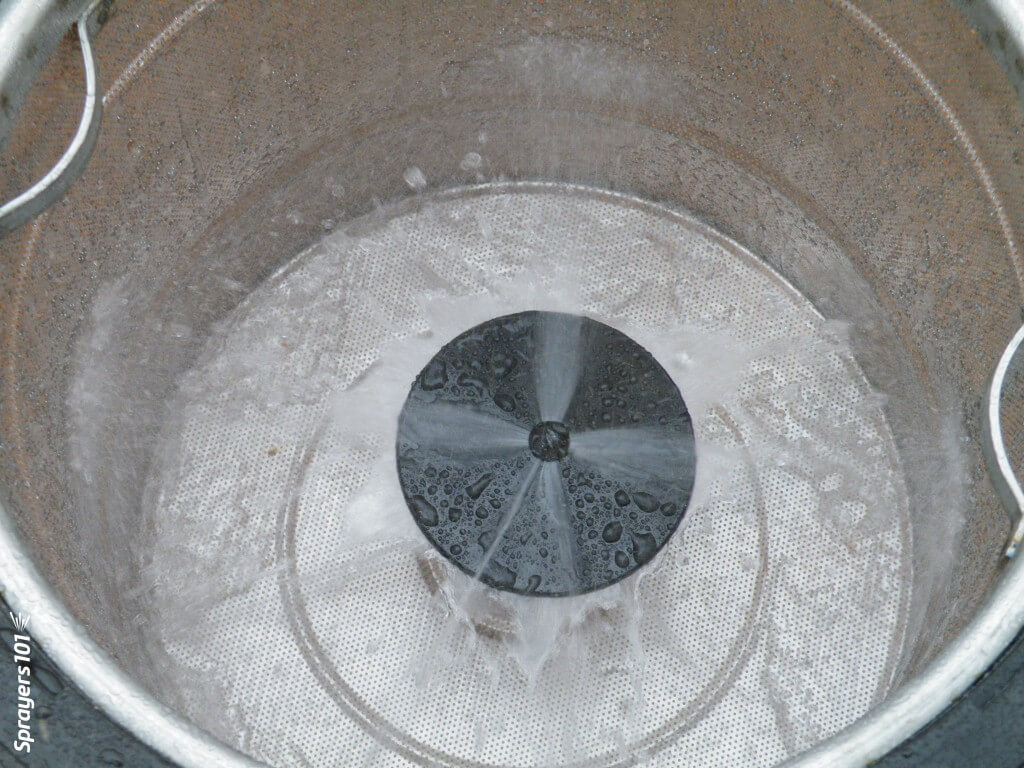

Hydraulic Agitation is accomplished by returning a portion of the pump output to the tank. Cylindrical and oval tanks are the ideal configuration for the sparging (i.e. rinsing) type of hydraulic return agitation system. This system consists of a tube located longitudinally along the wall of the tank, with volume booster nozzles aimed at the centreline so they sweep across the bottom. Volume booster nozzles take a small amount of water pumped into their venturi chamber and create a vacuum that draws three to four times that volume from the surrounding water and expels it out the end.

For hydraulic agitation to the effective, the agitator nozzle(s) should be fed by a dedicated line from the pressure side of the pump (not the pressure regulator). They should have a valve to throttle the flow or completely shut it off to prevent foaming.

Adding pouches

Adding pesticide to the sprayer may not be straight-forward. Many airblast operators, for example, place dissolvable pouches in the basket so they can be broken up by the hydraulic return, or the fill water. But fill water often splatters out of the basket, and the bags can “puff” open, releasing product into the air. This creates unnecessary contamination and operator exposure. Preferably, mix a slurry.

Some elect to temporarily remove the basket and add the pouches to a half-full tank with the agitator on. However, the pump can suck in the partially dissolved bag which then coats the intake screen. I know of one operator that had to rebuild the pump because the Viton seals burned out. This operator now premixes slurry, or adds pouches to the basket while standing upwind and away from potential splatter

Adding pesticide to the sprayer may not be straight-forward. Many airblast operators, for example, place dissolvable pouches in the basket so they can be broken up by the hydraulic return, or the fill water. But fill water often splatters out of the basket, and the bags can “puff” open, releasing product into the air. This creates unnecessary contamination and operator exposure. Preferably, mix a slurry.

Choose the safest and most effective method for your situation.