The level of filtration required for any given spray operation depends on the materials sprayed and the nuisance factor: That is, the balance between lost productivity from plugged nozzles and the effort required to address them during rinsing.

There are opportunities to install strainers at the tank opening (usually a basket), the suction-side of the pump, each section line, and behind the nozzles. While we’ve yet to see an operation that uses all four (speciality or field operations), the suction strainer and line strainers are required bare-minimum.

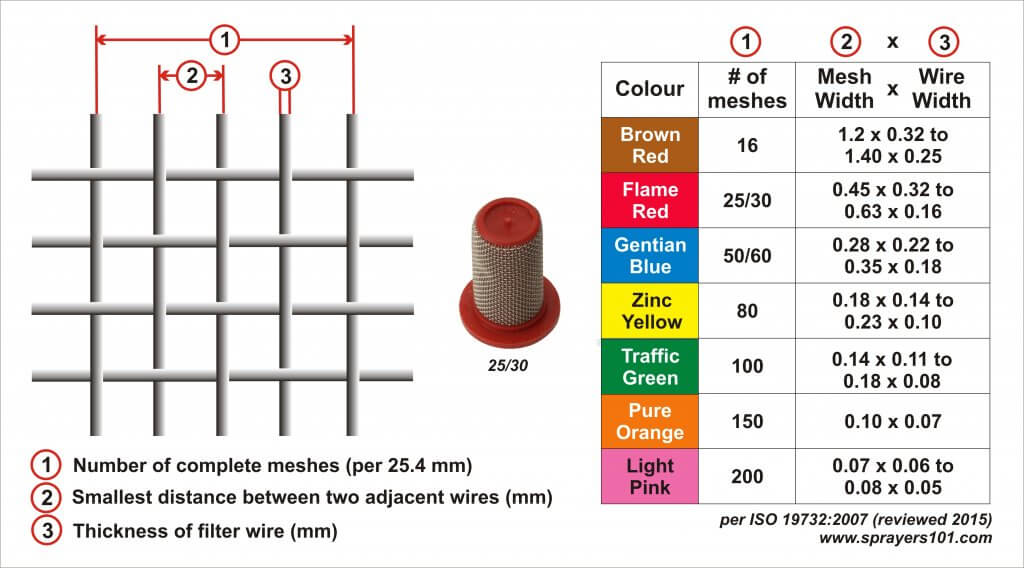

This infographic explains how strainers are classified. Be aware that older strainers may use a different colour code (e.g. 50 mesh used to be red – now it’s blue).

Each level of filtration should get progressively finer, ending with the nozzle strainers being slightly finer than the nozzle orifice. Nozzle catalogues will often advise you on which strainer is appropriate for the nozzle you are using.

When we ask why operators don’t use nozzle strainers, the response is either “Because they plug” or “It’s one more thing to clean”. Well, if your nozzle strainers are plugging, it’s likely because you have an agitation (see here) or mixing issue (see here and here) further up the line. They can handle a lot before the spray pattern begins to suffer … but yes, you do have to clean them regularly so they can continue their good work.

Running water through any strainer often fails to remove plugs and debris, which are a source of contamination that can wreak havoc later on. They have to be removed and physically scrubbed during rinsing. We ran a demo to show why this irritating process is still a must-do: Here.

If you use an airblast sprayer, you should use slotted (not mesh, which plug too easily) nozzle strainers. Beyond the obvious benefit of preventing plugged nozzles, the strainer shoulder plays a role in keeping the nozzle snug in the nozzle body. Without it, you may need additional gaskets to prevent leaks. Be aware that some nozzle strainer designs can plug a nozzle body. Learn more here.

If you use a field sprayer with clean carrier water, liquid formulations and large nozzles, you may never need nozzle strainers. But, if you’re using a lot of dry formulations, if your agitation is under-powered, or if your fill water is less than pristine (we’ve seen frogs in sprayer tanks) then you might consider them… even if they are a nuisance to clean.