This article was co-written with Mike Cowbrough, OMAFRA Weed Management Specialist – Field Crops

What is Tank Mixing?

Tank mixing is the practice of combining multiple registered agricultural products in the sprayer tank for application in a single pass.

The Pros of Tank Mixing

- Efficiency: If the timing makes sense, a single pass saves time and reduces trample/compaction. E.g. A “weed-and-feed” application of fertilizer and herbicide in corn.

- Resistance management: Multiple modes of action help prevent resistance development and combat existing problems.

- Improved performance: Labels may require adjuvants to condition carrier water or reduce drift (utility adjuvants) or to improve the degree of contact between droplets and the plant surface, or enhance product uptake or rainfastness (activator adjuvants).

The Cons of Tank Mixing

Tank mixing requires caution and careful investigation. Should tank mix partners prove to be incompatible, the consequences can be subtle or dramatic, but are always negative. There are two kinds of incompatibility.

1. Biological or Chemical Incompatibility

This form of incompatibility may not be immediately apparent following an application. Some level of crop damage or impaired efficacy occurs, which may impact yield or warrant an additional “clean-up” application. This is the result of product synergism or antagonism.

Synergism (Crop damage)

When products synergize, the application becomes too potent. For example, an adjuvant could affect crop retention or uptake, exposing it to more active ingredient or overwhelming crop metabolism. The result is damage to the crop we are trying to protect.

Antagonism (Reduced efficacy)

When products antagonize, the application becomes less potent. There are several examples:

- pH adjusters in one product may reduce the half-life of another product (e.g. The fungicide Captan has a half-life of 3 hours at a pH of 7.1 and only 10 minutes at a pH of 8.2.)

- Active ingredients may get tied-up on the clay-based adjuvants in other products (e.g. glyphosate tied up by Metribuzin).

- One product changes the uptake/retention of another. For example, a contact herbicide burns weed foliage beyond its ability to take up a lethal dose of systemic herbicide.

2. Physical Incompatibility

Physical incompatibility affects work rate and efficacy. Products form solids that interfere with, or halt, spraying. It can also make sprayer clean-up more difficult. For example, weak-acid herbicides lower the pH of the spray mix, reducing the solubility of Group 2 herbicides (i.e. imidazolinones, sulfonylureas, sulfonanilides). The oily formulation then adheres to plastic and rubber surfaces in tanks, connectors and hoses.

There are many forms of physical incompatibility:

- Liquids can curdle into pastes and gels that clog plumbing to such an extent that flushing cannot clear it and a manual tear down is required.

- Dry formulations don’t hydrate or disperse, becoming sediment that clogs screens and nozzles. Even if they are small enough to spray, they reduce coverage uniformity. For example, a dry product added behind an oil gets coated, preventing it from hydrating.

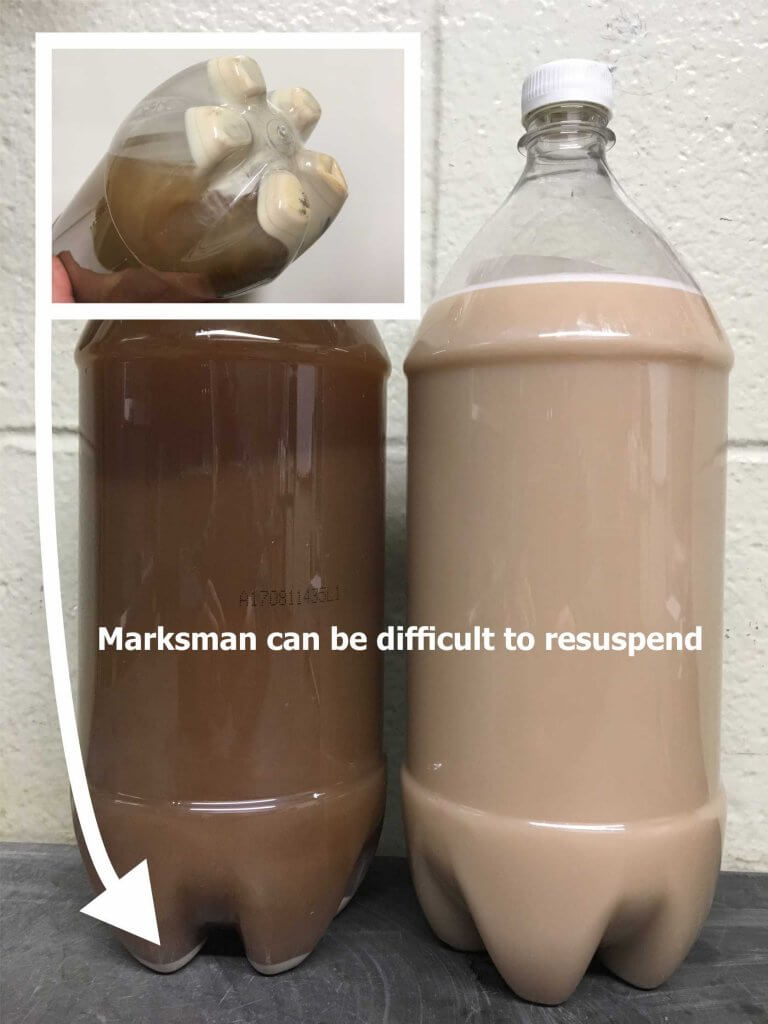

- Certain product combinations may cause settling, or one partner is more prone to settling. If the sprayer sits without agitation, settled products may or may not resuspend. Even if they do resuspend in the tank, they may remain as sediment in lines.

- Certain product combinations may cause foaming, or one partner may be prone to foaming, causing overflows or breaking pump suction. When products foam, dry products added through the foam may swell, preventing hydration.

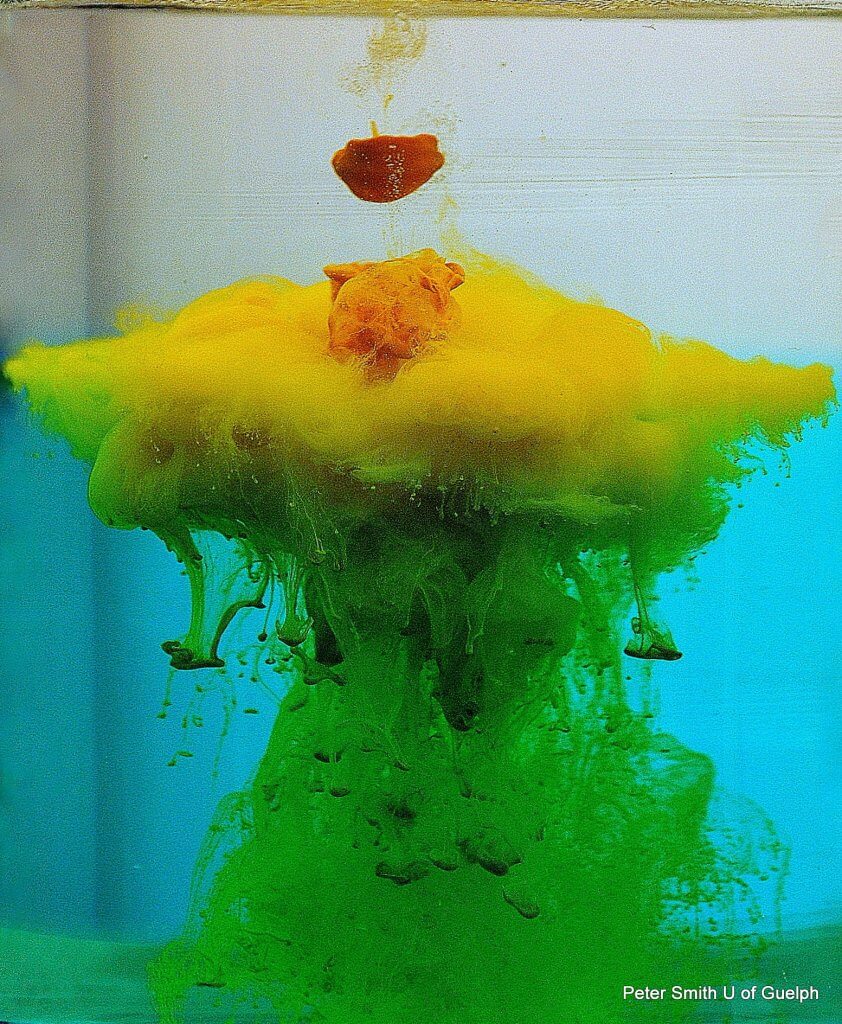

- Phase separation occurs when products layer in the tank. Consider oil and water. Even with agitation, the active ingredients may not be uniformly suspended in the tank and coverage uniformity will be reduced during spraying.

Due Diligence – Preventing Tank Mixing Errors

Incompatibility is often a function of the inert ingredients in pesticide formulations (e.g. thickeners, adjuvants, defoamers, stabilizers, solvents, etc.) and not the active ingredients. The more products you add to the tank, the more likely you’ll encounter an issue. It is prudent to perform a jar test to confirm physical compatibility. Remember, even if registered tank mix partners support mixing, your pace, mixing order, and water quality/temperature could cause issues.

Do not decide to try a new-to-you registered tank mix during loading. Even if you’ve used these products successfully in the past, formulations change without notice. Plan as much as possible off season when there is time to do the following:

Consult the pesticide labels

Pesticide labels are always the first point of reference. They should be obeyed even if they contradict conventional practices. Booklet-style labels that come with the products are long, difficult to search and may not be up-to-date.

In Canada, it is faster and easier to go to the PMRA Label Search website and search labels in PDF format. In other countries, consult the manufacturer’s website for label information. For each tank mix partner, use <CTRL>+F to find the following keywords:

- Do Not Mix

- Mix

- Hours

- Agitation

- Fertilizers

Consult manufacturer and crop advisors

You’re likely not the first to consider a certain tank mix. Learn from those that have been there already:

- Consult your chemical sales representative. They know their products best and want to see you succeed. They may have insight that is not found on the product label.

- Consult local government or academic extension programs for an unbiased opinion.

- Enlist the help of a professional crop advisor.

It is a good practice to get tank mix recommendations in writing. If something should go wrong, liability is an important concern.

If you’ve made a mess – The Reverse Jar Test

It happens. We’ll use this real-world situation as an example:

“I mixed up a batch of MCPA 500 A and Glyphosate at ¾ recommended label rate, but then got delayed on application with a stuck drill. I came back to the sprayer and found a nasty chemical precipitate – like waxy chunks. Agitation didn’t break them down. I dumped the tank out as I didn’t want to pump it through the booms. How do I clean up the chunks in the system?”

We forwarded this question to ag chemists Dr. Eric Spandl (Land of Lakes) and Dr. Jim Reiss (Precision Laboratories) and developed this response:

“Wearing appropriate personal protective equipment, physically remove the “chunky” material. A lot of time can be wasted (and rinsate water created) by experimenting with various concoctions, but if you do choose to try a compatibility agent, first try it in a mason jar. If it works to dissolve the material, it can be added to the tank with water and agitated. If not, you are down to manual cleaning: hot water under pressure.”

We dubbed this process “The Reverse Jar Test”. Do not add hot water, cleaners or compatibility agents until the reverse jar test confirms success. You may create a larger problem. Of course, the best advice is to not put yourself in this position to begin with. Once again, don’t make mixing decisions at the inductor bowl – make them before ordering product.

Tank mixing regulations in Canada (January, 2023 update)

The following legislative framework is specific to Canada, so readers in other countries should consult their own regulatory authorities.

Paragraph 6(5)(b) of the Pest Control Products Act (PCPA) states that no person shall use a pest control product in a way that is inconsistent with the directions on the label. In 2020, a public consultation was held to consolidate and clarify tank mixing requirements. This led to Regulatory Proposal PRO2020-01 (Streamlined Category B Submissions and Tank Mix Labelling – July 3, 2020). Essentially, it stated that tank mixing would be allowed if there was text on the product label that specifically permitted it. This could be a specific tank mix combination, a general statement permitting mixing, or both.

A new general label statement that permits tank mixing was proposed to consolidate tank mixing information in one place on the label and allow greater flexibility in terms of tank mixing options. The prohibition against tank mixing products with the same mode of action was removed, and the reference to tank mixing with a fertilizer is now an optional component of that statement. The general label statement reads as follows:

“This product may be tank mixed with (a fertilizer, a supplement, or with) registered pest control products, whose labels also allow tank mixing, provided the entirety of both labels, including Directions For Use, Precautions, Restrictions, Environmental Precautions, and Spray Buffer Zones are followed for each product. In cases where these requirements differ between the tank mix partner labels, the most restrictive label must be followed. Do not tank mix products containing the same active ingredient unless specifically listed on this label.

In December of 2022, Health Canada released a guidance document describing the federal tank mixing policy. This document is not part of the PCPA, but is an administrative document intended to facilitate compliance by all stakeholders. Registrants have until December 20, 2024 to update their extension material to align with amended product labels and guidance documents. Similarly, users of pest control products will be provided the same transitional period to adjust their purchasing and production practices to align with the provisions of this document. This means the policy will be in full effect on December 20, 2024. After that, applicators in Canada can only apply tank mixes that appear specifically on a product label, or tank mixes of products whose labels include the new general tank mixing statement.

Summary of the guidance document

Tank mixing is not permitted when a potential tank mix partner’s label has some exclusionary statement, such as:

- Forbidding mixing. E.g. “Do not mix or apply this product with any other additive, pesticide or fertilizer except as specifically recommended on this label.”

- Limiting tank mixes to only those specifically listed on the product label.

During the label transition, guidance relating to tank mixing may be found under a section specific to tank mixing, and/or under other sections as in the following examples:

- Directions for use: E.g. “When tank-mixes are permitted, read and observe all label directions, including rates and restrictions for each product used in the tank-mix. Follow the more stringent label precautionary measures for mixing, loading and applying stated on both product labels.”

- Buffer Zones: E.g. “When tank mixes are permitted, consult the labels of the tank-mix partners and observe the largest (most restrictive) spray buffer zone of the products involved in the tank mixture and apply using the coarsest spray (ASABE) category indicated on the labels for those tank mix partners.”

- Resistance Management: E.g. “Use tank mixtures with [fungicide/bactericides/insecticides/acaricides] from a different group that is effective on the target [pathogen/pest] when such use is permitted.”

If there are no directions on the labels, don’t tank mix them.

If your situation does not fit these examples, the following table (Appendix A at the bottom of the Guidance Document), lists several other examples examples of different tank mix wording scenarios for registered pest control products.

Table 1: Permissibility of tank mixing based on various combinations of label statements related to tank mixing

| Product X label says | Product Y label says | Can I tank mix? (Y/N) |

| Nothing (silent on tank mixing) | Nothing (silent on tank mixing) | N |

| General tank mix statement | Nothing (silent on tank mixing) | N |

| Nothing (silent on tank mixing) | General tank mix statement | N |

| General tank mix statement | General tank mix statement | Y |

| General tank mix statement | Tank mix with Product X | Y |

| Tank mix with Product Y | General tank mix statement | Y |

| Tank mix with Product Y | Nothing (silent on tank mixing) | Y |

| Nothing (silent on tank mixing) | Tank mix with Product X | Y |

| Tank mix with Product Y | Tank mix with Product X | Y |

| Tank mix with Product Y | Exclusionary statement (and label does not include a specific Product X tank mix) | N* |

| Exclusionary statement (and label does not include a specific Product Y tank mix) | Tank mix with Product X | N* |

Tank mixing adjuvants

According to the PMRA, the rules surrounding the tank mixing of adjuvants remain the same as they have been since 2009, and are not included under the new guidance document. While the PCPA does not reference adjuvants specifically, they are prescribed to be pest control products in the regulations (Pest Control Products Regulations s.2(b)). The general reference in the PCPA that applies is s.6(5)(b).

Therefore, the label for at least one tank mix partner must specify the use of an adjuvant, and only registered adjuvants labeled for the crop and for tank mixing are permitted. For example, tank mixing the herbicide Reflex with a registered soybean oil adjuvant not labelled for the use, or with an unregistered food grade adjuvant, would not be acceptable.

For more information on Canada’s Tank Mixing Policy

For more information, please contact Health Canada’s Pest Management Information Service.

Academic Resources

Even when products are potentially compatible, issues can arise from errors in mixing order, pace, carrier volume, carrier quality and agitation. These are discussed in our article on sprayer loading and jar testing.

In 2018, Purdue University published “Avoid Tank Mixing Errors”. It is an excellent reference.

In late 2022, Australia’s GRDC released a comprehensive guide on pesticide mixing and batching (within the context of the Australian agronomic environment, of course), which can be downloaded for free, here.

Finally, you can watch a 2021 presentation on tank mixing (below). It was delivered to a grape growing audience, but much of the content applies across agriculture. There are a few “oops” moments where I didn’t say quite what I meant. I misread the Sencor dissolution / filtration work. And, I really didn’t answer the last question about mixing herbicides. The answer should have been to consult labels and local resources, such as OMAFRA’s Crop Protection Hub. Note that any discussion of Canadian regulatory policy may have changed in light of the new 2022 Guidance Document.