This article was co-written with Mike Cowbrough, OMAFRA Weed Management Specialist – Field Crops

The time and attention spent during sprayer loading is a worthy investment. It ensures that the products in the tank perform as intended and reduces the chance of physical incompatibilities.

The label

Pesticide labels are always the first point of reference. Labelled mixing instructions should be obeyed even if they contradict conventional practices (see Mixing order, below). Consult this article on tank mix compatibility for more information on how to quickly and easily consult labels for each of your tank mix partners.

The carrier

Typically, the carrier is water. Water plays a very important role in tank mixing that is often underappreciated. Take some time to read Les Henry’s 2016 Grainnews article called “The Coles Notes of Water Chemistry“. You can also read about pH and water hardness. It should be noted that pH and the resultant hydrolysis that can affect product half-life is typically an insecticide issue (not fungicide or herbicide). The famous example is Captan, which has a half-life of 32 hours at pH 5, but only 10 minutes at pH 8. Michigan State did a great summary (in 2008 and on US product formulations) which you can find here.

Finally, learn how to read a water quality report, here.

Carrier volume

Products dissolve better in higher volumes. The sprayer tank (vat, inductor, etc.) should be at least ½ full or water before adding the first product. In the case of a fertilizer carrier, it may look like water, but it contains high levels of salts that tie up free water and reduce solubility. For fertilizers, a higher initial volume of ¾ full is required.

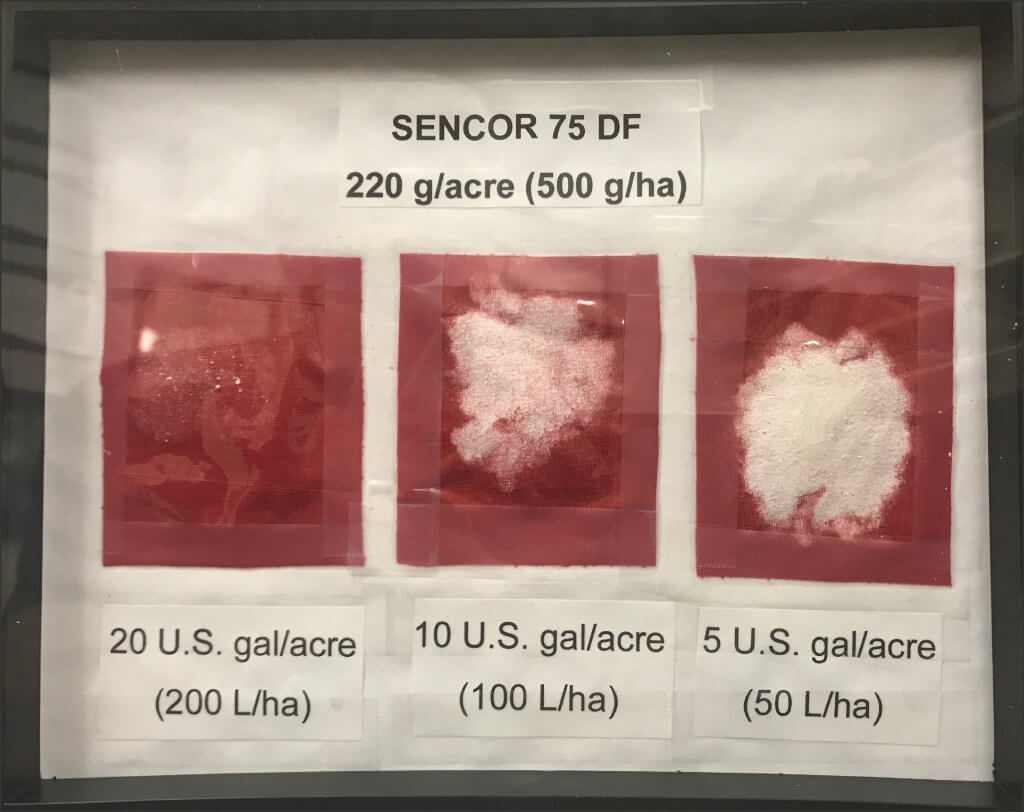

The incomplete dissolution of products can leave hard-to-clean residues, plug fluid lines, and result in a non-uniform application that reduces efficacy. The risk of incompatibility is greater with low carrier volumes and high product rates (especially dry formulations). This is a common problem in regions that use low water volumes to apply multiple tank mix partners.

Carrier and product temperature

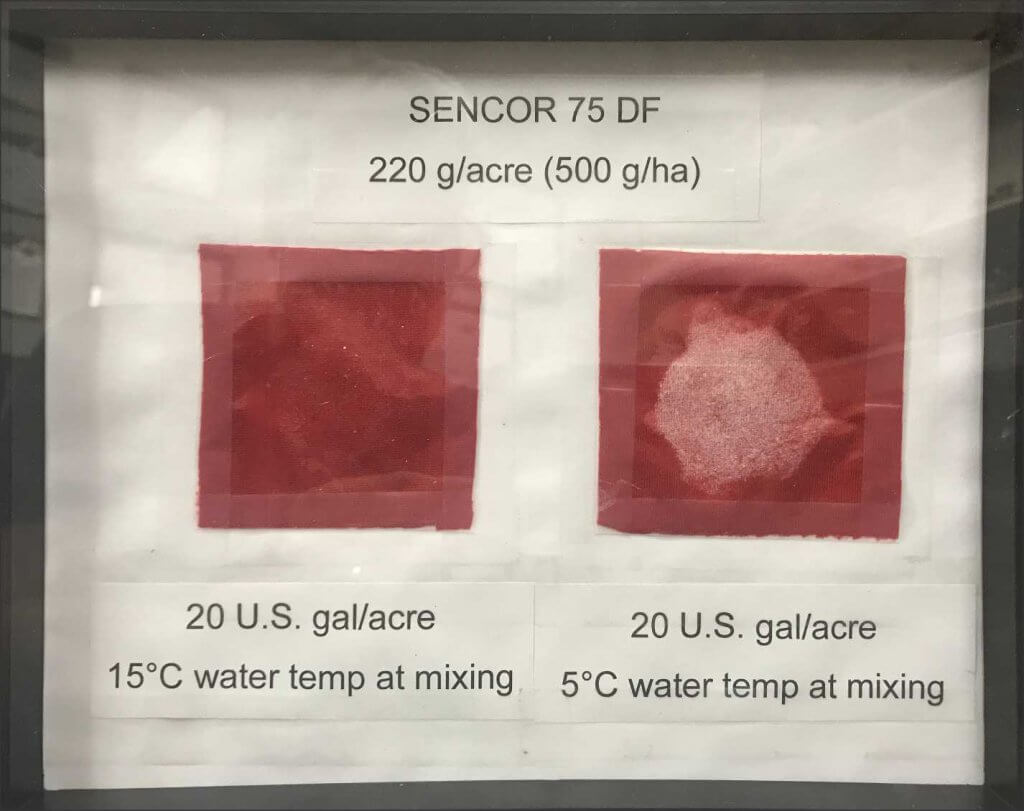

Both carrier and product temperature affect mixing. Imagine mixing sugar in hot tea versus iced tea – more sugar dissolves more quickly in hot liquid. Here are three common temperature-related issues:

- Dry formulations and liquid flowables take more time to disperse (consider using a pre-mixed slurry).

- Emulsified concentrates and oil might form gels rather than milky blooms.

- Water soluble packages might not dissolve completely and could plug filters and nozzles – or clog the pump intake.

Water and fertilizer are very different carriers. Beware of carrier-specific incompatibilities

Agitation

Agitation should be on-going during mixing and spraying. When agitation is too low, products may not disperse or suspend and can settle out. In the case of leaving a sprayer overnight without agitation, settled product may or may not resuspend. See this article.

When agitation is too aggressive (e.g. full agitation when tank is less than half full) product can foam, causing overflows or breaking pump suction during spraying. Over agitation can also cause dispersed products (e.g. emulsifiable concentrates) to separate and cause clumping that looks like curds.

When agitating, the surface of the carrier should be closer to a simmer than a rolling boil.

Pace

Products may require more than five minutes between additions. This is especially important when carrier or product is cold, or when adding dry products. When products are added too quickly, they will not entirely disperse or suspend, which could result in a physical incompatibility with subsequent additions. Learn more about the importance of time and patience during loading.

While efficient sprayer loading is an excellent opportunity to improve your work rate, complicated tank mixes still require time between additions. To save some time, sprayer operators pre-hydrate dry products in a smaller tank or use an extra tank to pre-mix whole loads and simply transfer them over.

Even when dry products appear to be dissolved, they may not be. Be patient.

Product formulation

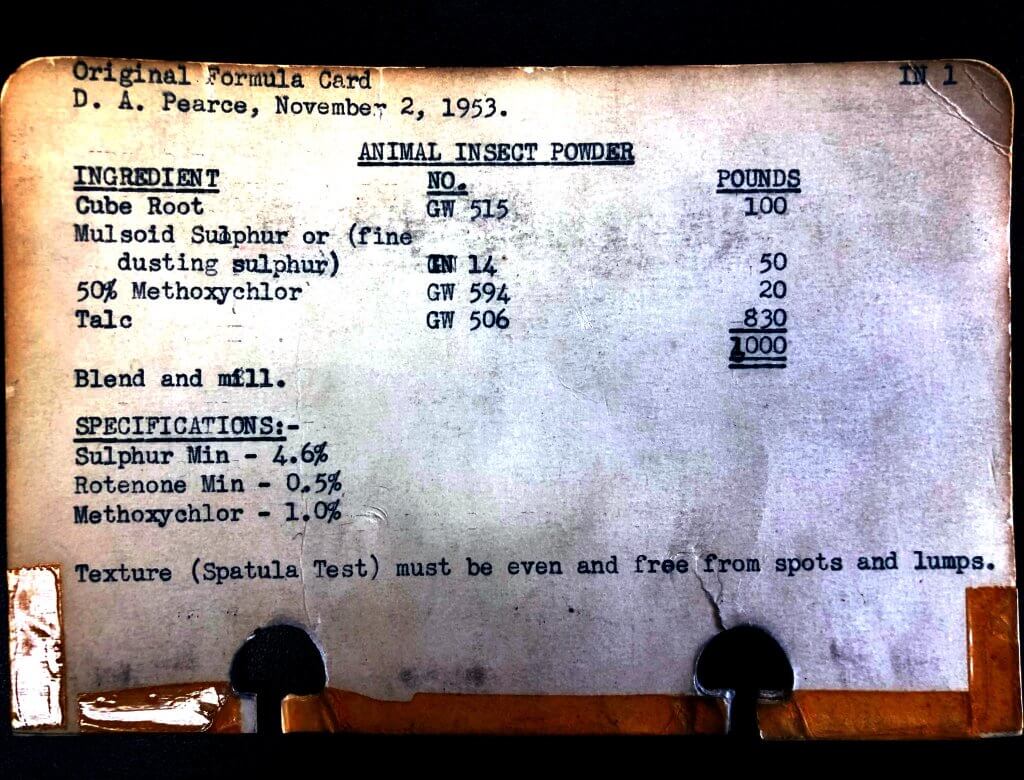

Product formulation is a complicated science. In the 1950’s a formulation might have three active ingredients and an inert filler. See the historic formulation index card shared by Dr. M Doug Baumann (formally with Syngenta, Honeywood). Today, a product can include ~40 ingredients with formulation testing lasting two to four years! The more products you add to the tank, the higher the risk of antagonism.

If you experience physical incompatibility during loading, don’t blame the last product you put in the tank!

Mixing order

The order in which you add tank mix partners is critical. There are several acronyms around to help you decide on your mixing order. Here are the top three:

- W.A.L.E.S. (Wettable powders, Agitate, Liquid flowables, Emulsifiable concentrates, Surfactants).

- BASF’s W.A.M.L.E.G.S. (Wettable powders, Agitate, Microencapsulated suspensions Liquid flowables, Emulsifiable concentrates, high-load Glyphosates, Surfactants)

- A.P.P.L.E.S. (Agitate, Powders soluble, Powders dry, Liquid flowables and suspensions, Emulsifiable concentrates, Solutions)

W.A.L.E.S. is not broken. In fact, formulation chemists expect it to work ~95% of time. Generally, soluble liquids are forgiving and can be added early or late. It’s the dry formulations and emulsifiable concentrates that require more care. When there are exceptions to the order, they are clearly indicated on the pesticide label.

W.A.L.E.S. is, perhaps, a bit simplistic. Products that fall within each “letter” have their own preferred mixing order that isn’t specified by the acronym. What follows is an expanded generic mixing order.

- Water-Soluble Bags (WSB) – Allow them to fully dissolve and disperse.

- Wettable Powders (WP)

- Water Dispersible Granules (WDG, WG, SG)

- Agitation to allow dry products to mix and disperse.

- Liquid Flowables (F, FL): Including, in order, Suspension Concentrates (SC), Suspo-emulsions (SE), Capsule Suspensions (CS/ZC), Dispersible Concentrates (DC), Emulsions in water (EW).

- In order: Emulsifiable Concentrates (EC): Microemulsifiable Concentrates (MEC) and Oil Dispersions (OD).

- In order: Solutions (SN), Soluble Liquids (SL), Liquid Fertilizers and Micronurients (when not already premixed with fertilizer).

- NOTE: Compatibility agents and anti-foamers should be added before pesticides. Adjuvants like Non-Ionic Surfactants (NIS), Crop Oil Concentrates (COC), Drift Retardants (DR), and spreader/stickers should be added based on specific label direction or based on their formulation, just like pesticides.

An example

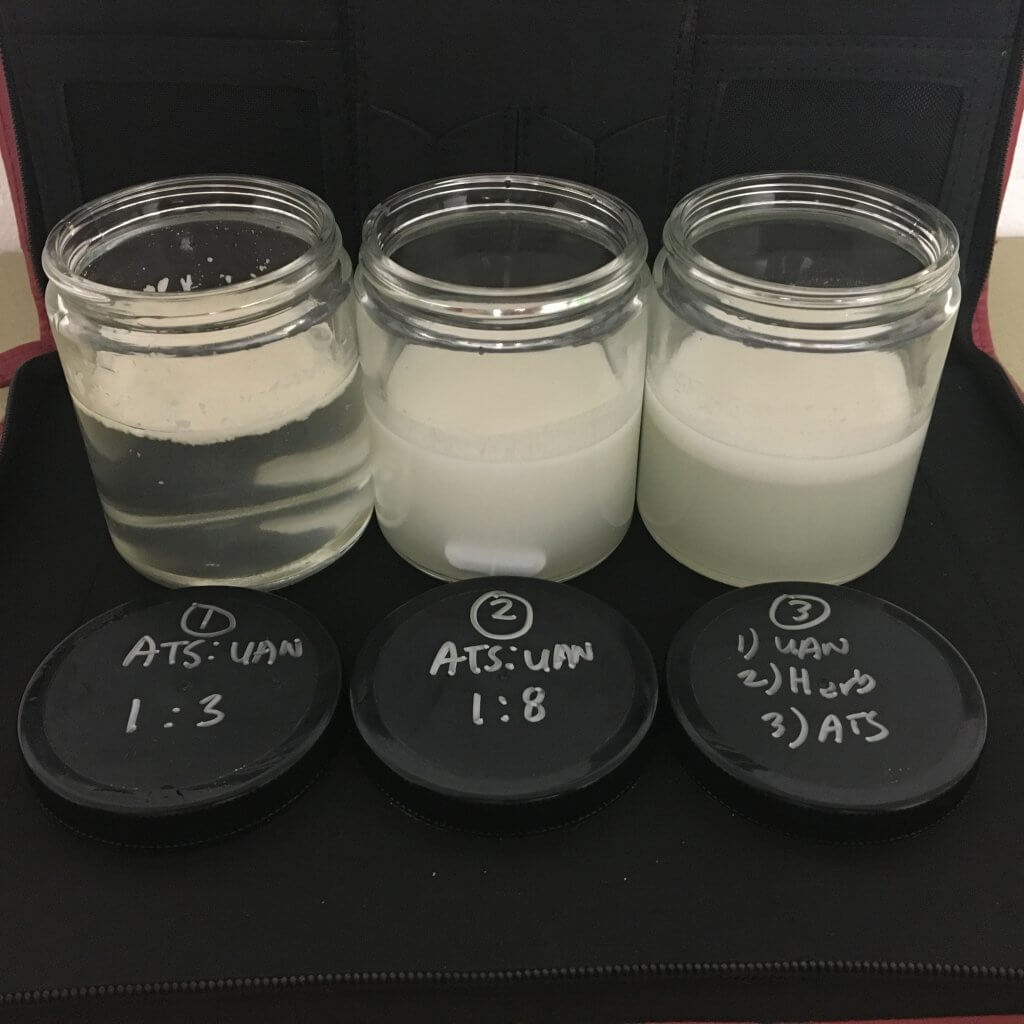

Micronutrients like sulfur (e.g. ATS) added to nitrogen-based formulations (e.g. UAN) can cause physical incompatibilities. This became a problem during “weed-and-feed” applications in Ontario corn, and thanks to the efforts of the pesticide manufacturer, we worked out a solution.

What follows is not only a good example of why mixing order is critical, but why growers should get into the habit of performing jar tests. Learn more about a real-world ATS example here.

Centre: UAN, followed by low-load ATS followed by Primextra worked.

Right: UAN followed by Primextra followed by high-load ATS worked.

Small-plot mixing order

Mixing errors are just as likely in small plot work as in commercial sprayers. Watch this short video case study describing mixing order for Elevore and glyphosate.

The jar test

Performing a jar test is like filling a sprayer in miniature. Follow all the same rules as filling your sprayer. Always wear personal protective equipment when performing a jar test. Do so in a safe and ventilated area, away from sources of ignition.

- Read all product labels. Know the product formulation (which affects mixing method and order). Look for information about the influence of carrier pH, hardness and any requirement for adjuvants. Defer to label instructions should they differ from these mixing steps.

- Shake any liquid products. This ensures the active ingredient and inert ingredients are thoroughly mixed.

- If using water as a carrier, add 250 ml to a 1 litre glass jar. For oil or fertilizer, add 375 ml.

- Agitate (stir) between additions. In a sprayer, agitation should continue throughout the mixing process.

- Add products in order (see Mixing order, above). Scale back the weights/volumes used to match the concentration intended for an actual sprayer tank (e.g. 1 kg product in a 1,000 litre sprayer tank is 0.5 g product in a 500 ml jar test). In a sprayer, you would flush an inductor with water between additions.

- Wait and check. Dry products and water-soluble packets must fully disperse and/or dissolve before adding the next product. Several factors affect the duration, but 3-5 minutes is typical. If testing water-soluble packets, include a ~1cm2 cutting of the PVA packaging.

- Top up the carrier to 500 ml.

- Measure pH using a digital meter (litmus papers may not be readable). This is best done after all products are added to account for their impact on pH and buffering capacity. If required, pH adjusters can be added at the end of mixing to ensure the solution is in the range required by the label.

- Let the solution stand in a ventilated area for 15 minutes and observe the results. If the mixture is giving off heat, these ingredients are not compatible. If gel or scum forms or solids settle to the bottom (except for the wettable powders) then the mixture is likely not compatible.

A jar test will only reveal physical incompatibility between products – it will not reveal any other form of antagonism.

Compatibility kits

When performing a jar test you must maintain the same product-to-carrier ratio as in a full-sized sprayer tank. This math is made easier with commercial compatibility kits such as the one from Precision Laboratories (below).

Such kits contain a few plastic “jars” and disposable micropipettes. By following the instructions included with the kit, you can easily reduce large labelled volumes (e.g. 1 kg of product in 1,000 litres) of multiple products to small volumes at the same ratio. In this case we assume the final volume would have been 1,000 L, and so we reduce all the quantities accordingly to get 500 ml. The following mixing order is provided as an example.

| Order | Ingredient | Quantity for 500 ml or 500 g of product labeled for 1,000 L of final spray volume |

| 1 | Compatibility agents | 5 ml (1 teaspoon) |

| 2 | Water soluble packets, wettable powders and dry flowables. Include a 1cm2 cutting of PVA packaging. | 15 g (1 tablespoon) |

| 3 | Liquid drift retardants | 5 ml (1 teaspoon) |

| 4 | Liquid concentrates, micro-emulsions and suspension concentrates | 5 ml (1 teaspoon) |

| 5 | Emulsifiable concentrates | 5 ml (1 teaspoon) |

| 6 | Water-soluble concentrates or solutions | 5 ml (1 teaspoon) |

| 7 | Remaining adjuvants and surfactants | 5 ml (1 teaspoon) |

Records and delayed reactions

Keep detailed records of what you mixed and how you mixed it. This is important for traceability (e.g. CanadaGAP) and for tracking successes and failures for next year.

The jar test itself can become a valuable record if it’s labelled and left in the chemical shed. You will see if products separate, precipitate or form residues. This may indicate if you can let a tank mix sit overnight or if it will require special attention during rinsing.

For example, a grower tank-mixed Enlist with Manzinphos, which seemed to mix and spray with no issues until they were rained out and had to park the sprayer with 100 gallons of tank mix still in the system. The mixture turned to “lard”, plugging up all of the lines, filters, and the pump. They had no choice but to disassemble the sprayer and dig some of the substance out with screwdrivers (see the picture of the filter below). Perhaps if they had run a jar test and left the jar overnight this problem could have been avoided.

Closed transfer

As a brief mention, an expansion of closed transfers systems for loading pesticides is on the horizon in North America. Manufacturers of these systems claim they will make loading more efficient, reduce operator exposure and reduce point-source contamination. Depending on the design, however, the operator may not be able to open pesticide containers to obtain samples for jar testing. This would be a great loss.

For more information

Learn more about physical and chemical incompatibility in our article on Tank mix compatibility. Be sure to download a copy of Purdue University’s 2018 “Avoid Tank Mixing Errors”. It is an excellent reference.