This article was co-authored by Mick Roberts (Owner/Editor of Pro Operator Magazine) with significant contributions from Jan Langenakens (Principal at AAMS) and thanks to insightful communications with both users and manufacturers of CTS. It now includes updates from the 2023 Agritechnica Trade Fair.

What is a Closed Transfer System?

Closed Transfer Systems (CTS) permit the direct transfer of pesticides from container to sprayer while isolating the process from the operator and the environment. Similar systems are already used with bulk pesticide containers and in other industries to dispense a wide range of liquids from household products to industrial chemicals. In the case of small-volume containers (e.g., up to 20 L), these systems include an integrated container rinsing function.

CTS are comprised of two parts: The Cap (or Adaptor) and the Coupler. The CTS cap is either pre-fitted on the pesticide container, or the user must remove and replace the existing, non-CTS cap with an adaptor. Generically, the container is then locked into the coupler, and a valve in the cap or adaptor opens to permit chemical to be drawn out. If a partial amount is required, the valve can be closed to re-seal the container for safe removal, and the coupler and lines can then be rinsed. If the full amount is required, then the container is also rinsed prior to removal.

Regulatory Requirements: Canada

Canada’s Pest Management Regulatory Agency (PMRA) considers the requirement for closed transfer when products go through their natural re-evaluation cycle. The requirement is primarily a means of reducing operator exposure and point-source contamination during filling, but can also be used to impose rate restrictions, or in response to reformulation. In recent years, several pesticides have had statements added to the labels regarding the requirement for a closed transfer system. These statements vary in their specificity, such as in the following two examples:

Product 1: “Requirement for additional personal protection equipment (PPE) and engineering controls when mixing/loading and applying to various crops.”

Product 2: “Closed mixing/loading systems are required. A closed system means removing a pesticide from its original container, rinsing, mixing, diluting, and transferring the pesticide through connecting hoses, pipes, and couplings that are sufficiently tight to prevent exposure of any person to the pesticide or rinsing solution.”

Questions and concerns have been raised by registrants and growers as these changes have appeared on pesticides with particularly important actives such as linuron, chlorothalonil and ethephon.

In some cases, registrants have avoided the requirement by splitting the label rate and promoting multiple applications to ensure rates do not reach the PMRA’s threshold for closed transfer. Another strategy is to remove small-volume formats and rely on Intermediate Bulk Containers (IBC or totes), which already employ closed transfer. If neither option is available, registrants may face expensive changes (which are currently unspecified) to their injection molding process. This is assuming the United States, which packs many of the small-volume containers for Canada, responds to emerging Canadian requirements.

Commercial horticultural and specialty crop growers (or field croppers with smaller acreages and diversified crops) are more likely to purchase pesticides in small-volume containers as opposed to a tote. For growers, the practical requirements for compliant closed transfer are not well understood. Most do not currently have CTS and feel a retrofit is overly burdensome (e.g. slow, expensive, complicated), incompatible with their equipment, or redundant with conventional PPE.

As Canadian agriculture comes to terms with these regulatory changes, the European experience offers valuable insight.

Regulatory Requirements: Europe

In Europe, reducing operator exposure and point source contamination during filling has long been a regulatory priority. Regulatory requirements for CTS are slated or already exist. The following dates are “fluid estimates” that will depend on the politics of each country. The Netherlands are planning to make it compulsory on liquid formulations by 2025. Denmark will follow by 2024-25 and Belgium by 2026. The Czech Republic already stipulates about 12 separate products must be used in combination with CTS, and a blanket requirement is under discussion. In some cases, growers will be granted a three-year transition period before they must show that they have a capable CTS. Currently the UK doesn’t yet have any concrete targets, but they have been testing CTS since 2017 and their experiences have informed product development and the creation of international standards.

Recycling

According to easyconnect, Germany is on the cusp of agreeing to accept both jugs and caps for shredding. Currently the caps are collected separately (if at all) because they aren’t typically rinsed. This is the same as in Canada. However, because the transfer systems also rinse the connection, the caps are down to the same 0.001% residue limit as the jugs, so as long as they’re dry, they’re both recyclable. Discussions are ongoing with France to make the same agreement.

Standards for CTS

The 2021 publication of ISO 21191 has greatly facilitated CTS development. It defines what a CTS is and specifies the testing methods and compliance criteria for both operator and environment-related safety. Summarizing key points in the ISO:

The CTS shall

- connect to containers and application equipment;

- control flow and measuring of all or a part of the container content;

- rinse the container into the application equipment;

- flush the CTS equipment as well as the interface;

- permit operation while using appropriate personal protection equipment specified on pesticide label and any associated operator’s manual;

- have clearly labelled controls;

- be designed to avoid any return of liquid to the clean water supply.

The CTS shall not

- cause leakage when the device is connected to the mix tank or application equipment;

- influence the circulation system of the connected application equipment;

- allow the introduction of air that promotes foaming or reduces pump performance;

- leave a residue level of more than 0.01% of the containers nominal volume following rinsing.

The ISO was reinforced by a recent Crop-Life Europe study that tested three systems applying for ISO certification. It demonstrated a more than 98% reduction in operator exposure (while using gloves) for the easyFlow M, GoatThroat, and Cleanload Nexus systems. These systems, and others, are described below.

Note: when using crop protection products, it remains a legal obligation for operators to wear the personal protection equipment indicated on the product label.

Commercial Systems

Pesticide container compatibility is fundamental to the success of any CTS design. There are exceptions, but many agrichemical companies in Europe and North America already employ a 63 mm screw cap for small-volume containers. According to the EPA (EPA 40 CFR Part 165 Subpart B), liquid agricultural pesticides in containers that are rigid and have capacities equal to or larger than 3 liters must have a screw cap either 63 or 38 mm in diameter and at least one thread revolution at 6 threads per inch. Depending on the CTS design, jugs may or may not require a tamper-proof foil.

The following systems are compatible with the 63 mm cap and are emerging as viable options at the time of writing. Some have been commercially available for several years and others are either new or still in development. Cost and availability will vary based on regional distribution and demand. Interested readers are advised to contact the manufacturer to confirm compatibility with their preferred products.

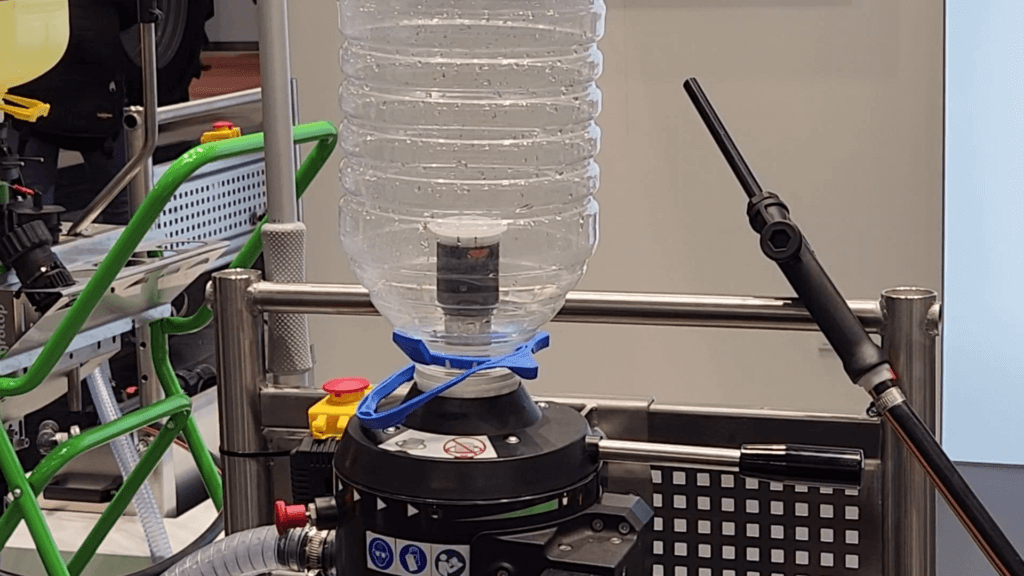

easyFlow (agrotop)

The easyFlow was developed with support from Bayer and has been available for more than 10 years. It requires the operator to remove the existing container cap and replace it with the easyFlow adaptor, which features a built-in knife that automatically cuts any foil seal. It is compatible with container sizes between 1 and 15 L. There are three versions of the easyFlow coupler.

easyFlow

The original easyFlow coupler installs directly to the sprayer tank. Once the pesticide container is joined (maximum 10 L format), product pours via gravity straight into the sprayer tank. The container can then be rinsed using an external water source (e.g. via a garden hose) with a min. ¾” diameter, anti backflow valve and water pressure between 3-6 bar.

easyFlow M

The easyFlow M is a standalone coupler that supports containers over 10 L and permits dosing via an integrated measuring unit just below the mounting point. The measuring unit holds up to 2,250 ml with a minimum volume of 60 ml and graduations of 20 ml (50 ml over the 400 ml mark). Product transfer is achieved either by gravity, or by a pump (e.g. Teed to the suction side of the sprayer pump).

According to agrotop, a 5L container under suction took 2-2.5 minutes to empty and clean during the Croplife study. For reference, some operators claim they are able to drain and triple rinse in less than a minute using a traditional pour into an inductor. An operator in wheat aims to fill in 5-10 min depending and uses 5-10 jugs. On the other hand, CTS users have claimed a “hidden savings” from the overlap in operations where the product from one jug is still entering the system as another is being drained and a third is being prepared. AgroTop sells an optional vent spike called a “Chucker” that makes the process faster still, but penetrating the jug raises questions about ISO compliance.

Empty containers can then be rinsed before removal, or partial containers removed leaving the adaptor on the jug. While this unit can be mounted on the side of the sprayer, most UK farmers that have trialed this system opted to install it on a portable cart.

easyFlow QF

This system is still under development and information is limited. The easyFlow QF coupler reputedly has all the features of the M but is compatible with all manner of container and employs a 12 VDC supply to automatically meter the dose (starting from a minimum 1 L volume). The rinsing process is electronically automated as well.

Videos of the easyFlow systems in use can be seen here and here. In the United states, these couplers are carried by Greenleaf Technologies. In Canada, it is also carried by FreeForm, a plastic molding company out of Saskatchewan.

GoatThroat

US-based GoatThroat has provided industrial liquid transfer solutions since 2001. Their CCS-8600 series requires the operator to remove the existing container cap and replace it with an adaptor with a siphon tube (which also pierces any foil). The container is then pressurized by a hand pump or compressor, forcing chemical into a measuring cylinder before it’s drawn into the sprayer. A clean water line then rinses the container (if emptied completely) and system before decoupling. The adapter can be left on containers if using partial volumes.

Comparatively, this system transfers and rinses more slowly than other small-format container systems and is entirely manual with multiple steps to transfer product. However, it now has a compressor option to replace manual pumping and it is highly customizable, making compatible with any container from a 1 L jug to a 1,000 L IBC tote. Further, its ability to transfer as little as 5 ml increments makes it a good option for small-acreage horticultural, specialty crop, and research farms where accurate partial loads are prioritized.

easyconnect cap (and Ezi-connect coupler)

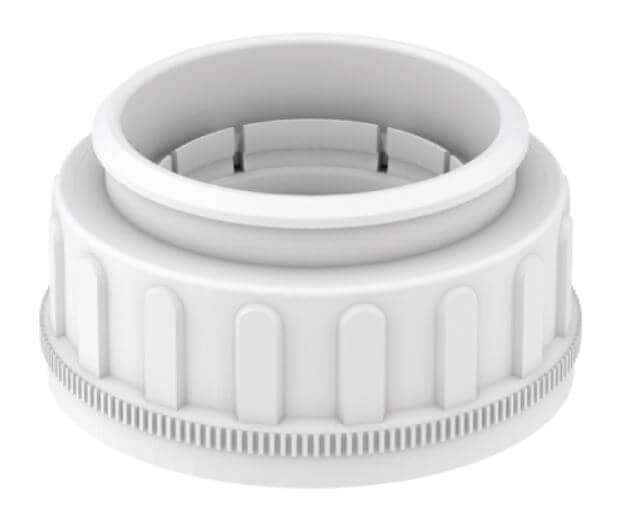

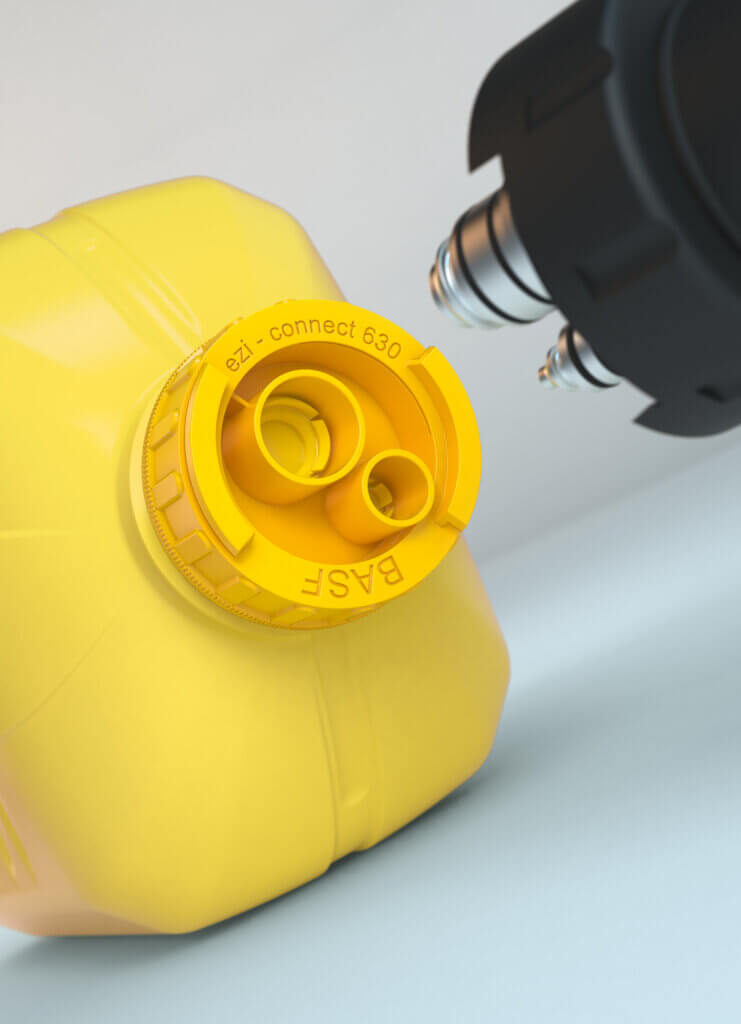

The easyconnect cap was originally developed by IPN Scholle with the support of BASF and is currently under development by Easy Cap and United Cap. It is compatible with container sizes between 1 and 15 L (possibly 20 L).

Because the cap is factory-fitted, it never has to be manually unscrewed or removed and works without requiring a tamper-proof foil. Its success is contingent on major agrochemical manufacturers agreeing to pre-fit it on their products. This has been facilitated by the easyconnect Working Group (ECWG), a consortium of ten major agrichemical companies, including those selling biological products and liquid fertilizers, that are supporting the European implementation of this format.

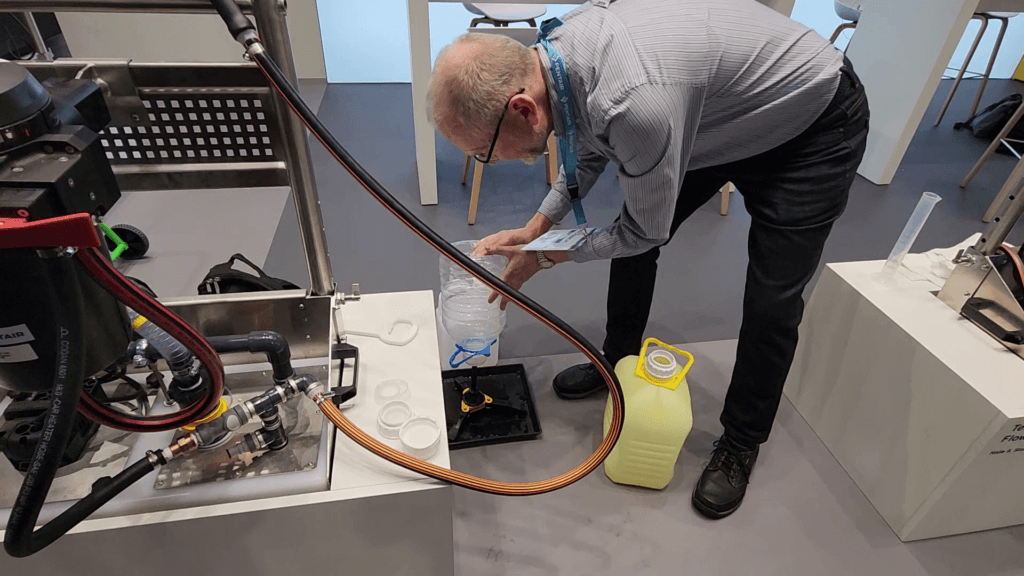

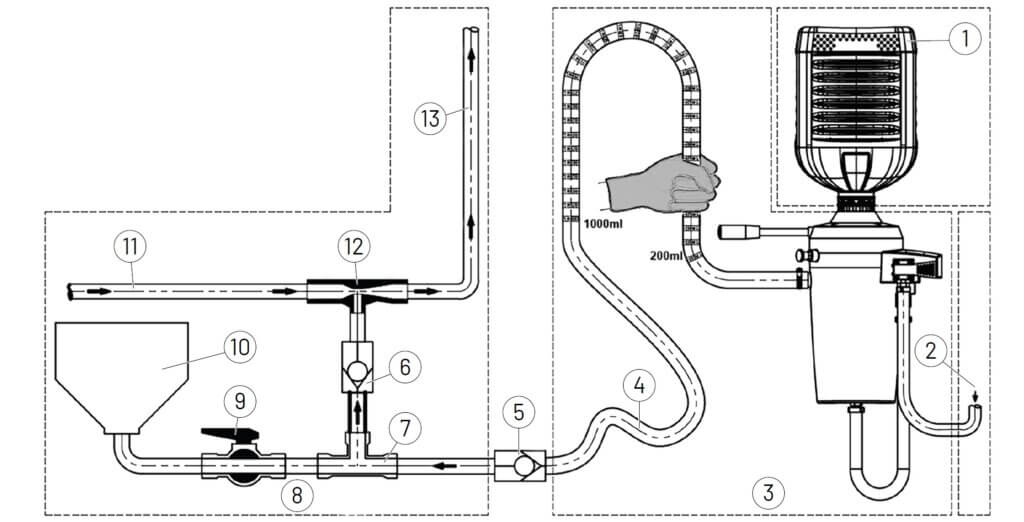

BASF displayed their compatible coupler, the ezi-connect at the 2023 Agritechnica in Hanover, Germany. Transfer requires the operator to snap off a dust cover, invert the container, and connect and lock it into the coupler. Another lever advances a probe and allows partial volumes to be dispensed via a vacuum generated by the hopper. Finally, a trigger controls rinsing water and undoing a catch allows the assembly to be rotated to improve cleaning without removing it.

easyconnect will be factory installed on 1, 5 and 10 L containers in 2024. This will not be the entire portfolio from all agrichemical companies in the easy connect working group, but will represent a “significant amount” that will demonstrate commitment. The ezi-connect coupler will be launched in Europe in the 2025-2026 season.

Cleanload Nexus (Pentair Hypro)

The Cleanload Nexus is a JKI-approved coupler designed for use with easyconnect caps on 1 to 15 L containers. The supplied 25 mm x 4 m suction hose can be connected by teeing it directly into the sprayer suction line ahead of the venturi (mounted to sprayer) or using a suitable dry-break coupler (mounted on a portable transfer station). The supplied 16 mm x 2.5 m rinse water hose connects to a clean rinse water source either on or off the sprayer.

It is entirely mechanical and has just two manual controls. The first is a lever that locks the cap in place. Rotating the lever controls the emptying rate, which is between 0.5 and 1 L/sec at 4 bar, depending on liquid viscosity. The time to empty and rinse a 15 L container at 3.5 bar is about 2 minutes, and users have stated that this is as fast or faster than traditional pouring and rinsing methods.

For dosing, it currently relies on the operator using scale markings on the side of the pesticide container, or the calibrated suction hose connected to the sprayer when dealing with larger volumes. The hose is, in our opinion, not a viable method for dosing. These methods cannot achieve the ISO +/- 2.5% dosing accuracy, so Pentair has developed a dosing cylinder add-on that sits between the Cleanload Nexus and the sprayer and provides +/-1% accuracy (anticipated launch in November 2023).

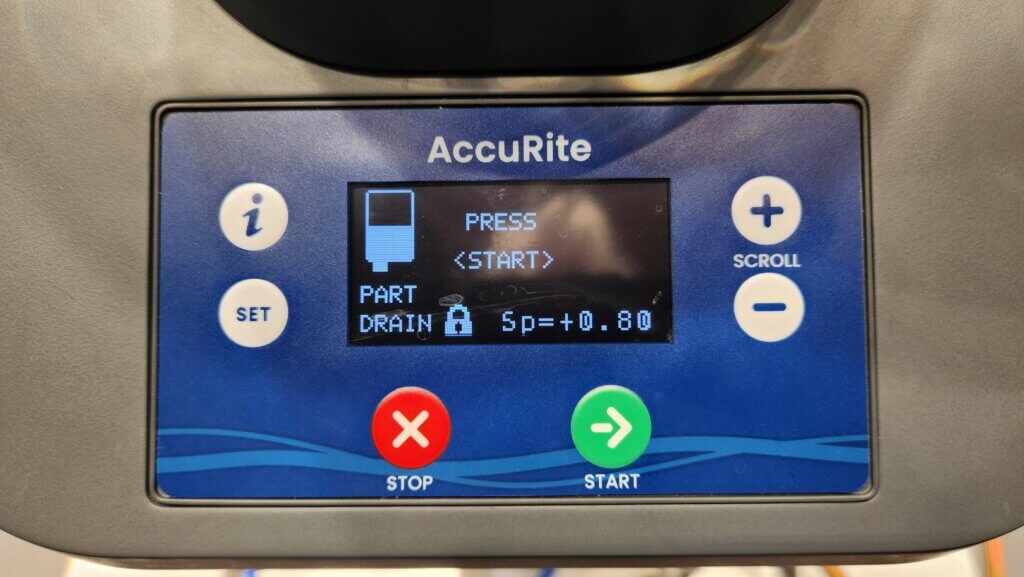

AccuRite coupler (Tefen)

Israel’s Tefen has produced dosing pumps and flow products for many years and began field testing the AccuRite CTS coupler in 2022. With a single digital interface to operate the filling process and mobile capabilities for remote management and cloud-based record keeping (e.g., date, time and chemical usage). It is designed to work with the easyconnect cap on containers ranging from 1 to 20 L. This is slow compared with the ~60L/min. from teh Pentair system, but Tefen is working to improve the speed.

Its diaphragm pump can deliver partial volumes at 0.1 L increments with an accuracy of +/- 2.5% of the smallest container used, and a minimum of 0.5 litres remaining in the container. Skip to the 1:50 mark to see the product reviewed (no English) in this video.

We saw one moulded into a Kverneland sprayer (now owned by Kubota) that was designed to couple with the current induction bowl. This is the first time a sprayer company has altered their design to accommodate a CTS and it points to the future.

Lechler’s LeC Coupler

Lechler’s Coupler is compatible with the easyconnect cap and features more electrical automation in its design. It requires a 12V electric supply and creates suction (typically from the sprayer’s venturi) to draw out the chemical. A small metering motor automatically moves the probe that enters the container to adjust emptying rate. It employs a pressurized water line running at about 6 bar.

The system will be controlled via a smartphone app, where the operator can choose partial or full emptying of product containers and control the operating and rinsing processes. Rather than metering flow, the unit employs three load cells with vibration compensation to weigh product. Lechler claims this is more accurate (automatic dosing to a set volume with +/- 2.5% accuracy), because it can compensate for different product densities. The user manually enters these values from product SDS, but likley QR codes will be used in the future.

The system will undergo further testing in 2024 and commercial availability is anticipated for 2025. Farmer’s Weekly covered the details of this system following Agritechnica 2023.

References:

- Options expanded for closed-transfer sprayer filling – Farmers Weekly (fwi.co.uk) (May 2022)

- Aspects of Applied Biology 147, 2022 International Advances in Pesticide Application Review of ISO 21191 Closed Transfer Systems Performance Specifications. Nancy Westcott and Jan Langenakens.

- Published abstracts from the Association of Applied Biologists’ Closed Transfer Systems Workshop hosted at the Silsoe Research Institute and Silsoe Spray Applications Unit, Bedford MK45 4HP, UK 11th May 2022

- Pro Operator Magazine, 2017-2023