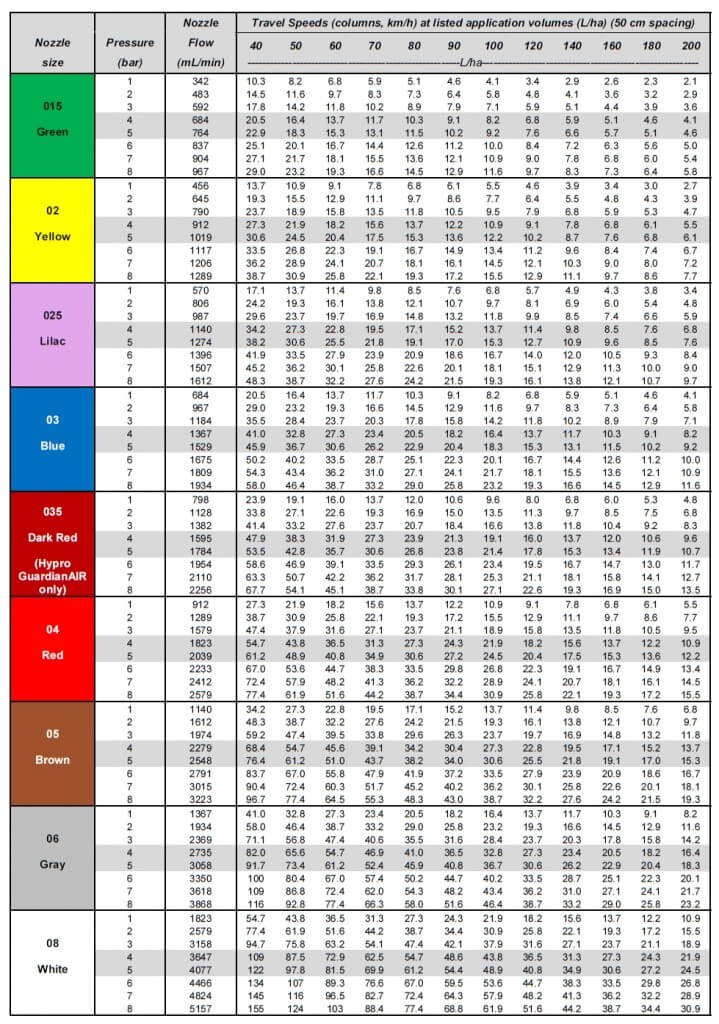

Pressure is integral to nozzle performance. Reducing hydraulic pressure reduces nozzle flow rate, increases median droplet size, and typically reduces spray fan angle. Increasing pressure increases nozzle flow rate, reduces median droplet size and typically increases spray fan angle. You can watch this Exploding Sprayer Myths video to learn how pressure, boom height and nozzle spacing […]