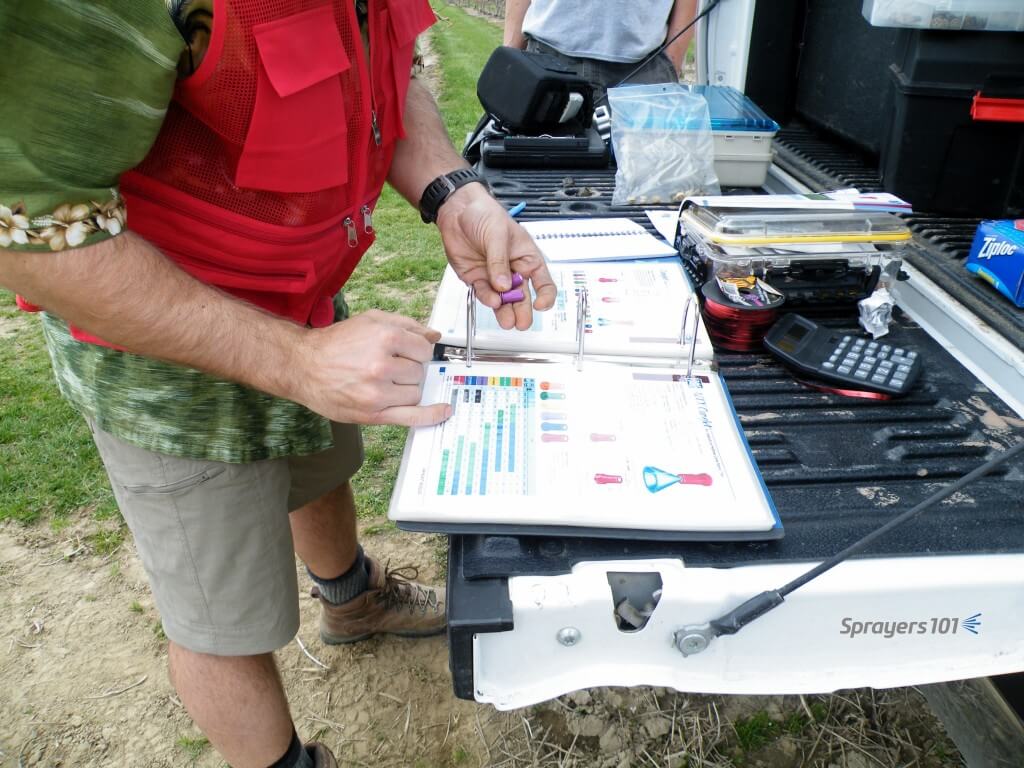

Us this handy visual guide to identify a mystery nozzle you may find on a field sprayer. We’ve included the most common low-drift nozzles found on North American, European, and Australian sprayers. The list does not contain any conventional flat fan nozzles. It’s in alphabetical order by manufacturer. First, a reminder of the ISO colour […]