Picking the correct nozzle for a spray job can be a daunting task. There is a lot of product selection, and a lot of different features. We try to break the process down into four steps.

1. Identify Your Needs

Before making any assumptions about the right nozzle for you, review your needs and objectives. Are you trying to reduce drift? Do you want better coverage? Are you moving towards more fungicide application? Do you need a wide pressure range?

It’s always a good idea to review your experience with your previous nozzle. What, if anything, would you like to change?

2. Identify Flow Rates

Most spray operations fall into one of three categories, (a) pre-seed burnoff (3 to 7 US gpa); (b) in-crop early post-emergence (7 to 10 US gpa); (c) late season application to mature canopies (10 – 20 US gpa).

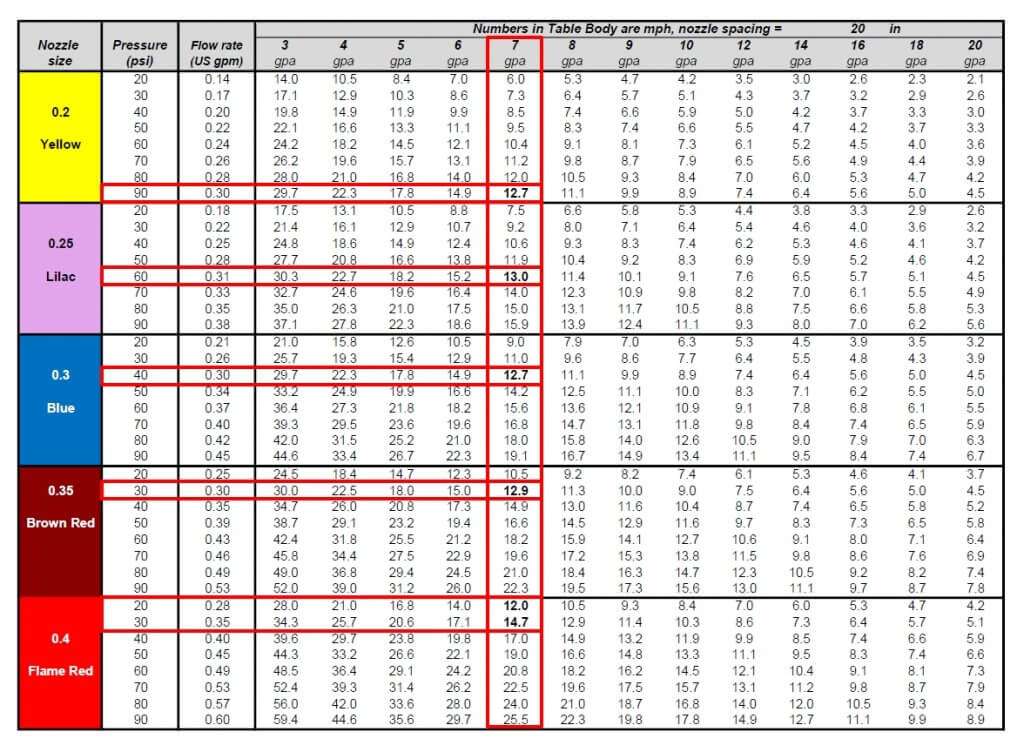

To find the right nozzle size, you need to know the application volume, the travel speed, and the nozzle spacing. Most sprayers have 20” nozzle spacing, but some have 15” spacing. Use these metric or US units charts to find the right flow rate for common nozzle spacings. Various on-line calculators from Hypro, Greenleaf / Agrotop, Lechler, or Wilger or their apps, are also helpful.

If you use our chart, the top row lists water volumes. The columns contain travel speeds. Travel speed is somewhat flexible and can change throughout the field.

Let’s assume the water volume is 7 gpa, and the desired application speed is 13 mph. Move down the “7 gpa” column, searching for 13 mph. You will encounter 13 mph about 5 times: 02 nozzle @ >90 psi, 025 nozzle @ 60 psi, 03 nozzle @ 40 psi, and 035 nozzle @ 30 psi (the 035 size is only offered by some manufacturers) and the 04 nozzle at about 25 psi.

Note that for the smaller nozzle sizes, the spray pressure is perhaps too high, and for the larger sizes, it is too low. Select a size that allows optimum nozzle performance and travel speed flexibility. In this example, the 025 size is optimal, producing an expected pressure of about 60 psi. The column for the 025 nozzle can now be used to predict the travel speed range from 30 psi to 90 psi, about 9 to 16 mph. For the 03 nozzle, the minimum speed would be 11 mph, too fast for some.

For Pulse Width Modulation (PWM), slightly different rules apply. See here for instructions.

3. Select the Nozzle Model

For general spraying, we recommend intermediate spray qualities ranging from Medium to Very Coarse.

These intermediate spray qualities offer good coverage at reasonable water volumes and good drift control. Their spray quality can be tailored with pressure adjustments to suit specific needs. For images, see here. In alphabetical order:

Air Induced:

There is plenty of selection in this popular category, all manufacturers offering similar specs and performance.

- Air Bubble Jet

- Arag CFA

- Greenleaf / Agrotop AirMix

- Hypro GuardianAIR (John Deere LDA)

- Lechler IDK

- TeeJet AIXR

Pulse Width Modulation:

PWM nozzle selection is improving, but some gaps in availability remain.

- Arag CFLD

- Easy Jet (also called PulZar in UK)

- Greenleaf / Agrotop BP

- John Deere LDM

- Wilger ComboJet MR110 & SR110

- TeeJet Turbo TwinJet (TTJ60)

- TeeJet Air-Induction Turbo TwinJet (AITTJ60)

All nozzles should be operated near the middle of their pressure range, for air-induction this is 50 to 60 psi or higher, a bit less for non air-induced types. This allows maximum flexibility when travel speeds change or when spray quality is adjusted with pressure.

For fusarium headblight, consider a twin fan nozzle.

Keep your booms no more than 15” to 25” above the heads for best results.

Air Induced:

There is an excellent selection of twin fans from most manufacturers.

- Air Bubble Jet Twincap

- Arag Twin Fan Air (TFA)

- Greenleaf / Agrotop TADF

- Hypro GuardianAIR Twin (John Deere GAT)

- Lechler IDKT

- TeeJet AI3070

Pulse Width Modulation:

Relatively poor selection, limited flow rate ranges or spray qualities available for some models.

- Arag TFLD

- Easy Jet Twincap

- Greenleaf / Agrotop BPDF

- TeeJet Accu-Pulse

- Wilger ComboJet Y-adapter (assemble custom twin)

For finer sprays (lower water volumes), simply increase spray pressure or consider a non-air-induced design.

There has always been a large selection of finer sprays on the market, remnants from a time when drift was less important. Very few offer flow rates above 06 or 08, decreasing utility for PWM systems.

- Hypro Guardian (John Deere LDX)

- Hypro 3D / John Deere 3D

- TurboTeeJet (TT) & TurboTwinJet (TTJ60)

- Wilger ComboJet ER110, SR110

Notice that conventional flat fan tips and most pre-orifice tips are absent from these lists. These nozzles are not recommended for herbicides because they produce sprays that are too fine for acceptable environmental protection (ASABE Fine and Medium). The added coverage afforded by such sprays only has value with low water volumes, and in those instances is more than offset by their higher drift and evaporation. An exception is the use of insecticides with contact mode of action targetting small insects such as flea beetles or aphids. In thes cases, finer sprays (ASABE Fine or Medium) may be required to provide effective tragetting.

Very high flows are sometimes needed (11010 and above, usually for PWM). When this occurs, conventional flat fans have merit because the higher flow rates of any nozzle usually create coarser sprays, and even conventional tips will create sufficient coarseness to prevent drift.

For the best drift protection, consider these tips.

The advent of the dicamba-resistant trait in soybeans has spawned interest in very low drift tips that comply with the label requirements for these products. Although superior for drift control, they are not well suited for low volume or low-pressure spraying, nor for contact herbicides or grassy weeds, as spray retention and coverage may be poor. But they are very valuable when drift control is paramount and when higher volumes can be used to maintain adequate coverage.

The following advice is based on the rules at the time it was written. These may be suitable for 2,4-D application in Australia under the newest APVMA guidelines (check spray quality to be sure it is VC or coarser). Many are also suited for Dicamba in Canada (must be XC or coarser), or dicamba in the US (must be on approved lists such as this one for Xtendimax or this one for Engenia, but caution is advised, some low pressure limits make them impractical. Always check that spray quality can be achieved at pressures that offer travel speed flexibility.

Air Induced:

Excellent selection. This market has received much attention in recent years.

- Arag CFA-U

- Greenleaf / Agrotop TDXL-D, TADF-D

- Hypro Ultra Lo Drift (ULD) / John Deere ULD

- Hypro / John Deere Ultra Lo Drift Max (ULDM)

- Lechler ID / ID3

- Magnojet MUG

- TeeJet AI / AIC

- TeeJet Turbo TeeJet Induction (TTI), TTI TwinJet (TTI60)

Pulse Width Modulation

- Greenleaf / Agrotop SoftDrop (SD)

- John Deere Low Drift Max (LDM)

- Hypro / John Deere ULDM

- TeeJet TTI, TTI60

- TeeJet Accu–Pulse

- Wilger ComboJet DR110 or UR110

Before making a selection, check the nozzle’s recommended pressure range and the spray qualities within that range from the manufacturer info. The target pressure for these tips may differ from your expectations.

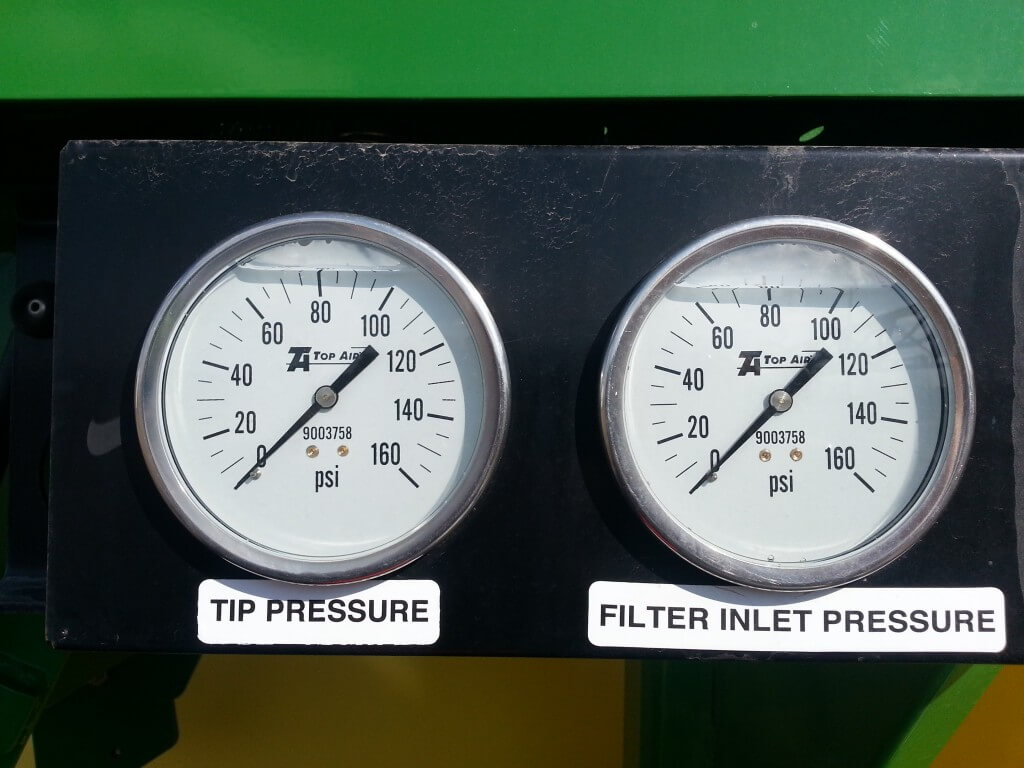

4. Tweak and Confirm

Under field conditions, the spray pressures which produce the desired water volumes can vary from the charts. Make sure you trust your pressure gauge reading and know the pressure drop from the gauge signal to the nozzles, particularly with PWM, where the solenoid adds additional drop. Add the pressure drop to your target pressure reading. If using a rate controller, use the pressure gauge as your speedometer to ensure optimal nozzle performance. Adjust travel speed until the nozzle pressure meets with your spray quality and pattern goals. If that speed is too slow or fast…you have the wrong size nozzle and/or water volume.

Spray pressure is more important than travel speed – make your pressure gauge your speedometer.

Visitor Rating: 5 Stars

Visitor Rating: 3 Stars

Visitor Rating: 3 Stars

Visitor Rating: 2 Stars

Visitor Rating: 3 Stars