The self-propelled sprayer revolution is complete in western Canada. Almost all sales of new equipment are self-propelled. In fact, the once thriving sector of Canadian-made pull-type sprayers, and the innovations they brought to spraying, has disappeared.

In its place we have self-propelled sprayers that offer plenty of power, large tanks, high mobility and comfort, and of course, the clearance required for late-season sprays. These features come at a cost: high capital expense, weight, fuel consumption and drift potential if the speed or boom height are not controlled.

The self-propelled machines are nice; however, customers are becoming concerned about overall value. Sure, the sprayer is the most-used piece of equipment on the farm, with the average field being treated four to five times per year. Does that justify the $500 to $700 k purchase price?

To answer this question, we need to evaluate the alternatives. Even though we’ve lost most North American pull-type sprayer makers, a few, such as Top Air, are left. A new pull type, the Connect Sniper, is being offered by Pattison Liquid. In addition, there are now several European manufacturers looking at our market. These bring large capacity, sophisticated booms plumbing and a narrow transport width. Let’s look at the issues:

Capacity

Not a problem. Top Air features tanks up to 2400 gallons and 132’ booms. Amazone builds a 3000 gallon tank twin axle sprayer (UX11200) with 132’ booms. The 230 gpm on-board diaphragm pump can fill the sprayer in 15 minutes. The Hardi Commander offers tanks up to 2600 gallons with 132’ booms. The Horsch Leeb TD12 is at 3170 gallons with 138’ booms. Equipped with air brakes, these sprayers can be trailed at up to 50 km/h.

Clearance

The pull-types themselves have adequate clearance for most crops. The limiting factor will be the tractor and the hitch point. The availability of a high hitch point, and an 80 mm ball, on European tractors, is a boon for this. Although it may be necessary to shield the low standard drawbar and belly, pull-type owners report no long-term effects from the lower clearance.

Tractor

The pull-type sprayer makes most sense if it allows the re-purposing of an existing tractor. The common yard tractor isn’t enough, as the high capacity sprayers may require >200 hp with front wheel assist, especially in softer ground or hilly terrain. Another requirement is that the track width match the sprayer, and the European standard of a 2.25 m track width (centre to centre) can be hard to match in North America. New rims on the sprayer can push the width out, but the resulting increased axle stress may be problematic; these issues should be considered in advance. Fortunately, powerful front wheel assist tractors are finding a place on farms, even as seeding tractors. The changing over from one implement to another during a busy time can be a hassle, with a dedicated rate controller requiring additional cab real estate. But with the lower capital cost of a pull-type, a new tractor that also has other utility on the farm may be justified.

Productivity

We’ve long maintained that productivity gain through increased travel speed creates more problems than it solves. It is virtually unavoidable to use somewhat higher booms with faster speeds, and it’s been proven that spray drift potential increases with travel speed. Instead, the sprayer features that save time are faster fill and clean times (reduced downtime), larger tanks (fewer stops to fill) and wider booms. Wider booms are easier to keep steady with slower moving equipment.

So how do typical self-propelled sprayers stack up against pull-types?

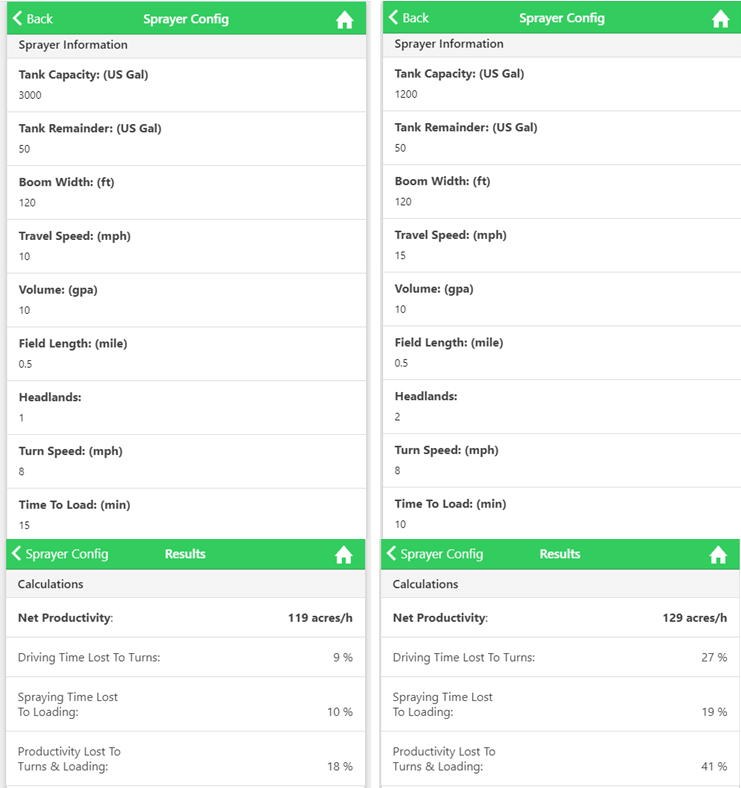

We compared two sprayers, a large pull-type with 3000 US gallon tank and a typical self-propelled with a 1200 gallon tank. Travel speeds were 10 and 15 mph, respectively, and fill times were 15 and 10 minutes. The slower pull-type turned in one headland, whereas the self-propelled used two to allow room for acceleration after the turn.

On half-mile runs, our “Productivity Calculator” at agrimetrixapps.com showed 129 acres per hour for the self-propelled and a respectable 119 acres/h for the pull type. The value of fast but infrequent fills and the more efficient turns made the difference for the pull-type. Use the app to compare other tank sizes, travel- and fill-speeds, or boom widths.

The specific design features of a sprayer may create additional productivity. For example, the ease of tank rinsing and cleanout can save time. European sprayers typically have lower remaining volume values, which increases the speed of tank rinsing and can eliminate the need for dumping tank remainders on the ground. Ease of filter inspection may seem trivial, but it permits more frequent confirmation that the system is clean and thus avoids potential future problems. An on-board pressure washer on the Amazone makes boom hygiene easier. It’s important to account for all these seemingly small gains because they add up.

Service

The success of any agricultural equipment relies on the equipment durability, fast availability of parts and service. Any new market entry will need to establish a dealer network, parts distribution system and superior service. This is no easy feat in a time of dealer consolidation. But without a drive train, there’s less to go wrong in a pull-type, and many plumbing parts are generic or can be obtained in metric equivalents.

Cost and Value

Prices vary, but a pull-type sprayer will usually cost less than half of a similar-sized self-propelled sprayer depending on the options selected.

With European-influenced equipment, the plumbing system will be more sophisticated, often offering recirculating booms, steering axles that follow in the tracks of the sprayer, narrow transport widths for greater road safety, an improved boom suspensions and levelling performance. It is safe to say that in terms of features, these sophisticated machines offer good value and many good design ideas. Operating costs are almost certainly lower, with better fuel economy and less drivetrain trouble.

The pull-type sprayer continues to have an important place to fill on our farms. With trade and weather anomalies lowering farm income, farmers are wary of being over-capitalized. It is conceivable that lower-cost and feature-rich alternatives to self-propelled units will have a fit. They certainly make sense on smaller farms that may not be able to utilize the full performance of a self-propelled, or on a larger farm that needs extra capacity but doesn’t want to bear the capital cost of a second expensive sprayer. The inherently slower working speeds allow for lower booms, less drift, overall improved deposit accuracy and uniformity. They’re worth a closer look.