How much horsepower (HP) do you need (really) when pairing a tractor and a towed sprayer or any other PTO powered implement? This important question should be asked BEFORE purchasing any towed implement. Surprisingly, there’s not much guidance out there, so you might hear answers like:

- Whatever my tractor has must be enough… whatever that happens to be.

- What?

- The right amount of HP is what I can afford. Erma, grab that milk can full of egg money…

- MOAR! (Yes, we know how “more” is spelled, but memes are funny).

Rating Tractor Horsepower

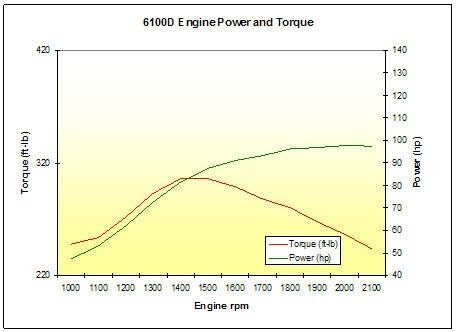

If you thought there was only one way to rate the horsepower of a tractor, well, you’d be wrong. At its simplest, horsepower is:

(torque × engine revolutions) ÷ a constant

We’ll expand on this later. The rub comes in how you define each of these factors and where you measure the power. Let’s start with something simple like engine speed, which is expressed in Revolutions Per Minute or RPM’s.

Engine Speed

So, if horsepower is the result of torque times engine speed, what speed do the manufacturers plug into the formula? One of two values are used:

1. Power Take-Off (PTO) Engine Speed

This is the engine RPM’s that produce the rated operating speed on the PTO. When the PTO is engaged, the engine is directly and mechanically connected to the PTO shaft. Therefore, maintaining the engine at the rated PTO speed, typically between 1,500 and 2,300 RPM depending on if it’s gas, diesel, turbocharged or not, will keep the PTO spinning at a uniform 540 or 1,000 RPM (the two typical PTO speeds) regardless of the driving speed.

2. Maximum Engine Speed.

This is the engine’s maximum intermittent operating speed… just shy of destroying said engine. An engine rated using the maximum speed gives you a false sense of security, because to get that horsepower you’ll be burning a ton of diesel, over-speeding your PTO implement, and wearing your tractor out very, very quickly. You wouldn’t drive your car around town in low gear because you’d redline the engine. Why would you do it to your tractor?

Horsepower Basics

OK, now we are ready to dig in a little deeper into defining tractor horsepower. What does it mean if, for example, your tractor is rated at 65 HP? We’ll skip the history lesson on watching the output of horses over an average day and move to the modern definition. Horsepower from a rotating shaft (such as the output of an engine) is:

Horsepower = [Torque in foot-pounds × Engine speed in Revolutions Per Minute (RPM)] ÷ 5,252

Total Versus PTO Horsepower

Perhaps our tractor’s 65 HP rating describes Engine Peak Horsepower. This is what the engine would produce on a test stand, and it likely uses the maximum engine speed. This rating is a bit disingenuous. Not only because you will probably operate it at rated PTO engine speed, but also because some power is lost to internal processes, like the power steering pump, automatic transmission pump, alternator, auxiliary hydraulics, et cetera. So peak engine horsepower isn’t usually a very useful number unless you are in marketing and like big numbers.

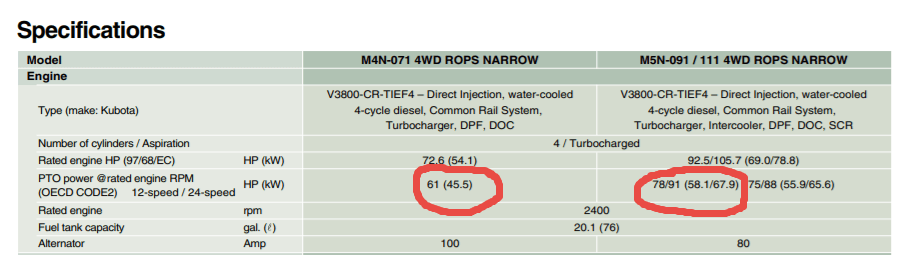

A more accurate and useful rating is the Power Take-Off (PTO) Horsepower. This is the amount of horsepower available to do work at the PTO shaft. This may be at the rated PTO engine speed or the PTO Maximum speed. Estimating power using either speed offers a much more realistic rating of what you have to work with. As previously noted, PTO Rated Speed is usually near the speed where the engine creates the highest torque per revolution. This is often called the Power Band. Operation in this engine speed range will use the least diesel and result in the greatest amount of life in the machine.

Another important thing about PTO Horsepower is that this is the total amount of power available to do work. This could all go to PTO when the tractor is standing still, but both locomotion and the horsepower required to run the implement need to be subtracted from this number. So if your tractor is indeed 65 PTO horsepower, that’s the actual amount of horsepower you likely have to work with in real life.

The Horsepower that Matters

To sum things up, PTO Horsepower is the number you really need to care about. All this up to now just to describe the nuances of how horsepower is expressed. No wonder HP is a topic that’s avoided. If you can find or download the manual, now you at least have the tools to get to how much horsepower you have to work with.

Maximum Load

In order to answer the question of how much HP you need, you must consider your operation. You need to size your tractor for the biggest load it will ever be used for, even if you only do that thing once a year. Typically this would be a sprayer, rotavator or a brush flail. The rest of the year you won’t burn much extra diesel if you aren’t using the power in a bigger tractor, but you can’t draw on horsepower that isn’t there in a smaller one.

Though it’s not common, you can have too big a tractor. You need only watch “Clarkson’s Farm” for ample evidence (and a chuckle).

The Basics of Estimating Load

Now that you have the extremes in mind, let’s get to scratchin’. There are three things you must know to determine the maximum load:

- Locomotion – The power needed to move the tractor and implement

- Implement Power – The power needed to operate the implement

- Safety Factor – This is a buffer that gives us a little extra just in case.

For the following guesstimates let’s assume you are doing orchard and vineyard work with a compact/narrow tractor. There really aren’t any hard and fast equations for this, but these will get you in the ballpark. If you are a nut grower with full sized tractors or a vegetable/field crop grower, you may need to scale up.

Locomotion

People discount it, but the power required just to move the tractor and the implement around is substantial. If the implement is a fixed tower sprayer with a 500 gallon tank, this might require 15-20 HP on flat, dry land. If your topography includes hills, or your terrain includes mud or tall grass, you may need to double that requirement. 45 HP just to move around before you even engage the PTO. Speed matters, too; If you are driving 5 mph, you’ll need twice the HP versus driving 2.5 mph.

Implement Power

The manufacturer of the implement should be able to tell you how much horsepower the implement requires. Small, three-point hitch airblast sprayers may only require 10-15 PTO HP. Larger tower sprayers may require 40-50 PTO HP. Brush flails may take 25-45 HP.

This is where things can get sticky and you need to make sure you’re both talking the same language. Some manufacturers will tell you how much power the implement takes, others will skip all the steps in this article and go right to recommending the size tractor they think you’ll need. If you’re unsure, ask. Be sure to factor in the locomotion requirements discussed earlier, the dealer may not understand your conditions in their general recommendation but usually can provide some clarity with a little more information from you.

Safety Factor

It’s always a bad idea to run at 100% of your power capability. Most of you reading this article are likely working with mid-life or older tractors with a few thousand hours on them. Ol’ Bessie loses some of the pep in her step over time. After engine break-in, the tractor will slowly lose power capability over its life. The harder you work it, the faster this occurs. Enthalpy happens (now that’s a great tee-shirt idea). Plan for it. Once you have an idea of your worst-case locomotion and implement power needs, add them up and give yourself another 15% (That is, multiply by 1.15).

Summing It Up

Now we can finally answer the question. In order to determine how much tractor horsepower you need, follow these steps:

- Understand the real PTO horsepower of the tractor you are considering. This is the only thing that matters. You should be able to find online documentation for this if it doesn’t come with the tractor or you’ve filed it somewhere that you’ll never forget…

- Establish the maximum load you are likely to encounter. Calculate this by multiplying the sum of Locomotion and Implement Power requirements by a 1.15 Safety Factor.

- If you are still unsure, discuss these factors with your trusted local tractor dealer, ensuring you are both speaking the same language. It is better to err on too much tractor than not enough, but do so within reason.

Looking at our original orchard application with a 500 gallon tank and a larger tower type sprayer, travelling around 3 mph:

35 HP for locomotion, 40 HP to run the sprayer and 15% safety puts us at 35 + 40 + [0.15 × (35+40)] = 86.25 PTO HP

Wishing you all MOAR POWER and perfect spraying weather.