This article continues from Part 1.

Droplet size

Droplet size influences droplet behaviour. The following table lists the pros and cons to changing droplet size when overall spray volume (e.g. L/ha) remains constant.

| Relative Spray Quality | Pros | Cons |

| Coarser Droplets | Lower drift potential because they resist deflection by wind and evaporation from heat and low humidity. | Lower droplet count may reduce coverage. |

| Greater mass means they move ballistically, propelled at higher speeds by pressure for greater distance. | May fall out of the spray before reaching the top or centre of the canopy. | |

| Coarser droplets do not penetrate dense canopies as easily as finer droplets. | ||

| Redistribution due to bounce, shatter or run-off may either improve or compromise coverage. | Redistribution due to bounce, shatter or run-off may either improve or compromise coverage. | |

| Finer Droplets | Higher droplet count may improve coverage (if they arrive at the target). | Higher drift potential from wind, and evaporation from heat and low humidity. |

| Finer droplets penetrate denser canopies better than coarser. | ||

| Finer droplets move unpredictably and require optimal air settings to direct them to the target. Sprayer design and air settings will determine if it is optimal for nearby or distant targets, but it is rarely if ever both. | Finer droplets move unpredictably and require optimal air settings to direct them to the target. Sprayer design and air settings will determine if it is optimal for nearby or distant targets, but it is rarely if ever both. |

It is preferred to use nozzles that create coarser droplets at higher rates (to compensate for fewer droplets) in the higher boom positions. They are more likely to stay on course to the tops of the trees, and when they miss, many fall out of the air rather than contribute to drift.

Learn more about strategies to reach the top of a canopy here.

Finer droplets have very little mass and therefore very little kinetic energy. This means they slow quickly (imagine throwing a feather) and require entraining air to carry them to the target. Finer droplets also evaporate quickly, particularly on hot and dry days (i.e. unsuitable Delta T conditions). If employed, they should be distributed in the lower-middle portion of the boom where they have the least distance to travel and are most likely to be intercepted by canopy.

Boom distribution

Unlike a broad acre boom sprayer, where each nozzle emits the same rate, an airblast boom can distribute spray unevenly. For a curved (axial) boom, the rule of thumb is to produce 2/3 of the overall volume from the top 1/3 of the boom. This compensates for the distance and greater proportion of canopy it is intended to cover.

A vertical (tower) boom positions each nozzle roughly the same distance from the target, and if that target is a hedged canopy, the spray can be distributed equally over the boom. Research has demonstrated that there is no appreciable advantage to one spray shape over another (e.g. flat fan, hollow cone, full cone) other than the spray quality they produce.

In extreme cases, operators might elect to “fire hose” spray to the tops of canopies using high pressures. This is achieved by using streaming nozzles or removing the swirl/whirl/disc plate in a disc-core combination nozzle in the top few nozzle positions. Given the heavy demand on the pump and the inaccuracy of the method, this should only be considered when air fails to reach the tops of trees.

Learn more about nozzling an airblast sprayer here.

Spray coverage and diagnostics

It’s well understood that spray coverage has a negative correlation with tree height. The irony is that in large nut trees the upper portion of the canopy produces much of the harvest. Taken collectively, this may explain why pest activity is also highest in the upper canopy. When choosing a spray volume and boom distribution, the metric is threshold coverage in the top 1/3 of the canopy. This requires us to define threshold coverage.

If ribbons and leaf movement represent the feedback mechanism for air settings, then water sensitive paper (WSP) is the choice for spray coverage. Placement in tall trees can be tricky, given that we are most concerned with coverage at the top, but this can be overcome by mounting the WSP on telescoping poles. Papers can be oriented horizontally to represent a leaf, or curled around the pole to give panoramic coverage and emulate a nut. Beware over-blowing in the lower canopy, which creates a shingling effect where leaves cover one another (or the WSP) and block coverage.

Fluorescent dyes and kaolin clay show spray coverage in situ, but there are drawbacks. Few growers will spray dye and come back at night with a black light to examine targets. Further, a target sprayed with dye or clay cannot be sprayed a second time, which means the grower can’t adjust the sprayer and try again in the same canopy. And finally, it’s very difficult to determine if there is more or less coverage with clay or fluorescent dye.

Learn more about how to use water sensitive paper here.

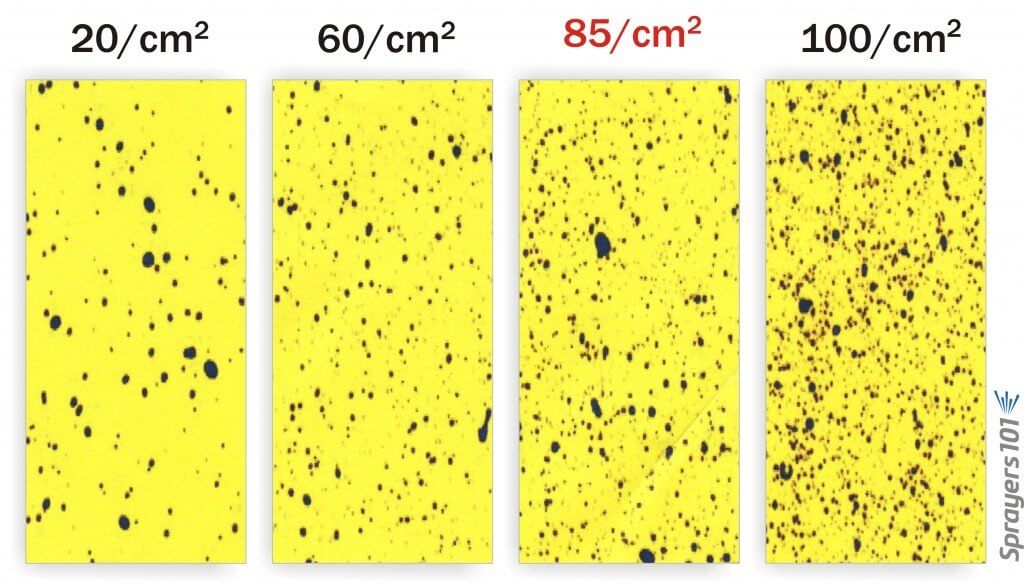

WSP is fast, cheap and effective. With the exception of drench applications, the most demanding spray application (e.g. contact fungicide) should produce a spray coverage pattern of 85 drops per cm2 and 10-15% total coverage. This threshold comes from collective research and experience in many horticultural crops, and should true hold for tree nut.

Be prepared to make changes to your sprayer calibration to compensate for tree height, canopy density, and weather conditions throughout the season. The feedback from water sensitive paper is far more accurate than shoulder-checks and leaf residue. It takes some time and effort, but it’s well worth it. Coverage is King.

What others have done

Researchers like Brad Higbee (Paramount Farming Co.) and Ken Giles (UC Davis) have explored spray coverage and efficacy from different sprayer configurations to combat Naval Orange Worm in almond. What follows is a summary of their observations. This information comes from their presentations and conversations with Brad.

Ten years of trials spanned travel speeds of 3-6.5 km/h, volumes of 1,400-2,150 L/ha, and sprayer-generated airspeeds (measured at source) of 80-290 km/h. They looked at efficacy, residue levels and WSP coverage both in leaves and on the nuts themselves. When comparing sprayer configurations, the target almond tree was divided into four levels:

- Level 1 = 1.8 m to 2.5 m (Lower canopy)

- Level 2 = 3.0 m to 3.7 m

- Level 3 = 4.2 m to 4.9 m

- Level 4 = >5.5 m (Upper canopy)

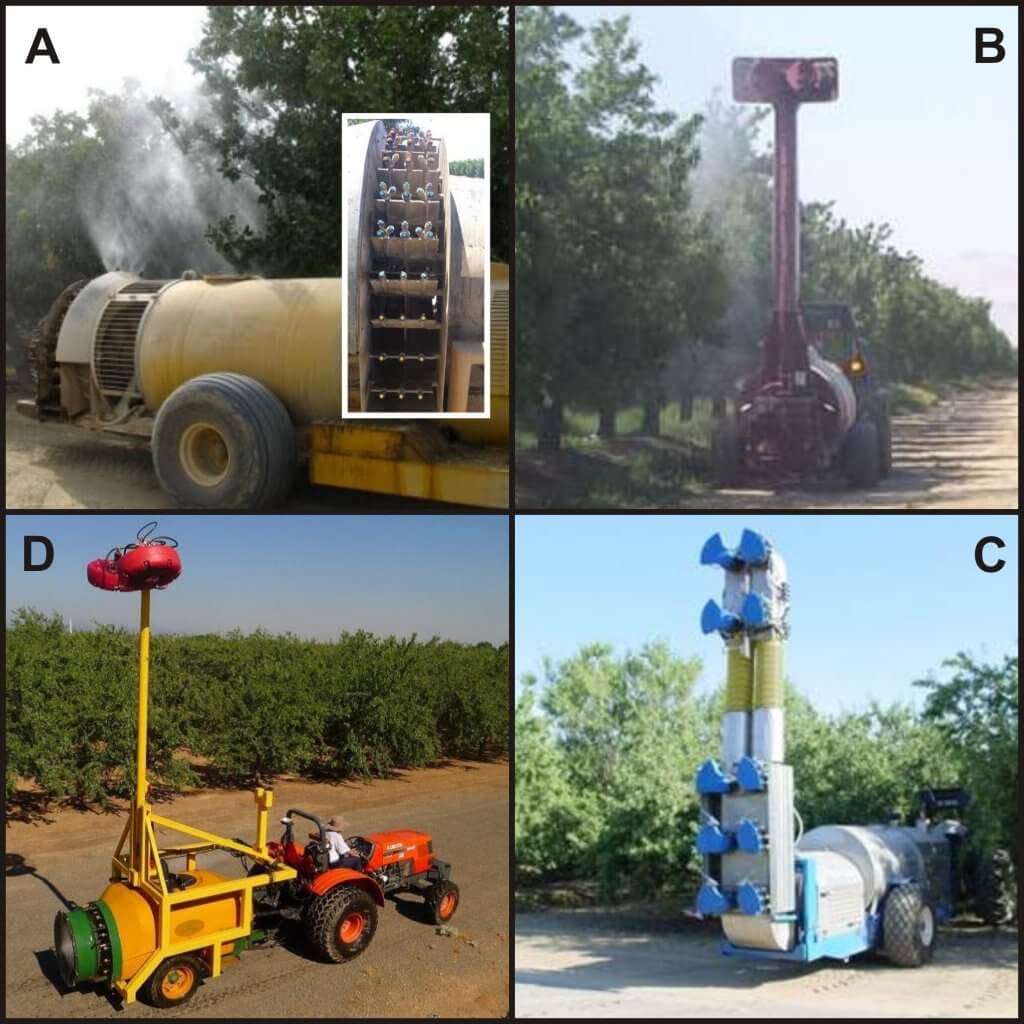

Many configurations were tested, but the following figure shows the top four. Of those not shown, most notable are the Bell 206 helicopter (280 L/ha at 50 km/h) and the Curtec AC 1000 Cross-Flow tower.

A. Air-O-Fan low profile axial D-240 (Also used Air-O-Fan 232).

B. Progressive Ag two-head 2650 electrostatic air-shear with 4 m tower (Also used 4.9 m three-head and 5.5 m four-head).

C. Blueline Accutech 10-head air-shear tower.

D. Low-profile axial airblast with two Sardi-style fans on mast. Upper fans set to 70% overall fan speed and spray volume. Axial fan and nozzles set to 30%

Here is a summary of their observations:

- Spray coverage and residue deposition was weakest in upper half (Levels 3 and 4) of canopy. Tower sprayers tended to provide more uniform coverage across vertical levels. For low-profile axial sprayers, most of the residues were deposited in the lower half of the tree.

- The Air-O-Fan low-profile axial had the highest overall residues. But, above 3.7 m there was severe drop off in coverage. PTO-driven sprayers seemed as effective as engine driven. Incremental improvements were observed on this sprayer when using multiple banks of booms, full cone and hollow cone nozzles.

- The Progressive Ag tower provided the highest residue deposition above 3.7 m and modest deposition in the lower canopy. While tower sprayers tended to provide more uniform coverage, the Progressive Ag was not significantly better than the Air-O-Fan overall.

- Aerial application (280 L/ha) combined with the Air-O-Fan low-profile axial sprayer (1,870 L/ha) did increase residues in the upper canopy, but did not result in greater damage reduction relative to the Air-O-Fan alone.

- Slowing the Air-O-Fan low-profile axial sprayer from 4 to 3.2 km/h resulted in 30% more coverage and 47% higher residue deposition overall.

- Electrostatic treatments did not perform well on WSP (small droplet size was suspected), but they were among the best in residue deposition at full volume and “delivered surprising residues at high speeds/low volumes”.

Brad has done remarkable work studying the impact of several sprayer configurations. While many were tested, there are still more that might be considered.

Canopy management

When all else fails, we are left with only one alternative: canopy management. Hedging and pruning the trees to create sprayer clearance opens canopies to spray (and light and air) and is a critical part of crop protection.

Learn more about the benefits of canopy management here.

Topping trees to bring them to a manageable height to improve coverage and reduce drift may be the only viable option for protecting the crop. I acknowledge that a great deal of nut production takes place in the upper third of the canopy, and it is beyond the scope of this article to discuss production and yield economics. However, when the crop is left unprotected, the yield quality is negatively impacted and it has been shown that a reduction in harvest weight is offset by the improvement in overall quality.

Where plants are very old and overgrown (such as macadamia), it is highly recommended that the orchardist engage a local crop expert and discuss a strategy for canopy management. There are many benefits, including:

- Improved harvest quality

- Fewer refills (saving time and water)

- Less time to spray means more timely applications

- Potential chemistry savings

- Savings in gas, noise and equipment wear and tear

- Potential for reduced off target spray drift

Summary

Spraying large nut trees is a challenging proposition. A number of inter-connected factors are involved and an operator must address all of them make spraying as efficient and as effective as possible.

- Adjust sprayer air settings first, using canopy penetration as your guide to travel speed.

- Distribute the 2/3 of the volume and coarser spray quality to the top 1/3 of the boom.

- Consider an air-assisted vertical boom configuration to improve coverage uniformity and reduce drift.

- Use water sensitive paper for critical coverage feedback and make changes based on that feedback.

- Develop a canopy management strategy to improve spray coverage and yield quality.