Managing the canopy of any perennial crop (e.g. pruning, hedging, leaf stripping, etc.) is an important consideration. The benefits are manifold: It affects the health of the plant, the quantity and the quality of the yield. It allows light and air to circulate and it keeps the crop manageable. From the perspective of an airblast sprayer operator, the reason for canopy management is quite simple:

If you can’t see it, odds are, you can’t spray it!

Picture this: It’s late April, and an apple grower and I are calibrating his sprayer. We achieve excellent spray coverage in the target block, shake hands and part ways. In late May I get a phone call from the grower. I assume it’s time to adjust his settings to match the growing canopy, but no… he had called to say he suspected apple scab in one of his blocks. Since I was the last person to adjust his sprayer, the unspoken implication was that I’d better come fix matters.

As I drove back out to his orchard, I considered what the problem might be:

- Bad product choice?

- Poor application timing?

- Spraying in inclement weather?

- Cutting rates?

- Resistance? (a long shot)

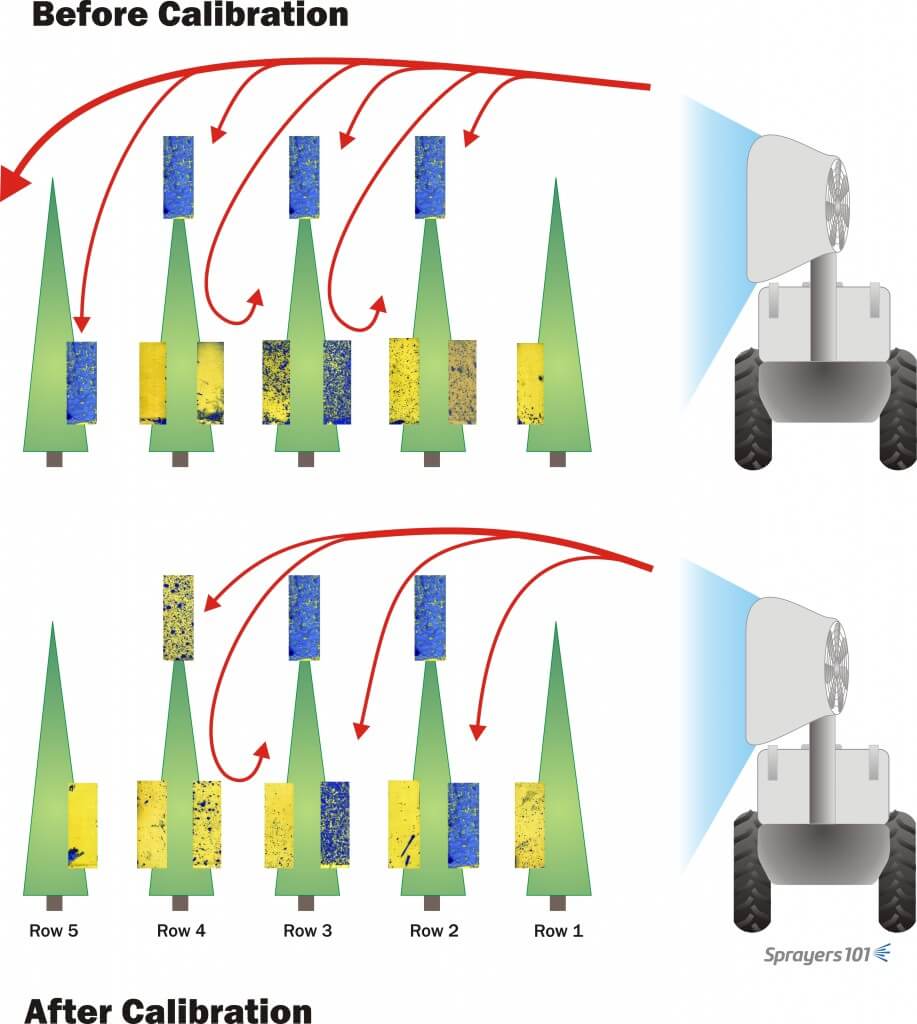

Maybe it was ego, but I couldn’t believe it would be the calibration. We left ample volume to provide sufficient coverage to get the grower to petal fall. We ensured the spray swath was higher than top of the tallest tree, accounting for wind and an uneven alley. We did everything right to match the sprayer to the canopy and leave enough buffer to get to petal fall.

When I arrived, he took me to a block I hadn’t seen before. We didn’t calibrate the sprayer to match this particular group of trees, but he figured since they were about the same height, the sprayer would do its job. It was immediately obvious to me what the problem was, but I knew if I simply told him outright, the lesson might not stick. And so, with respect to that old proverb, I taught him to fish rather than give him one. We spent the next few hours trying to fix our alleged calibration problem by exploring:

- Slower ground speed

- Higher fan gear

- Higher rpms to increase fan speed

- Changes to deflector settings

- Air induction nozzles in top positions

- Higher sprayer output

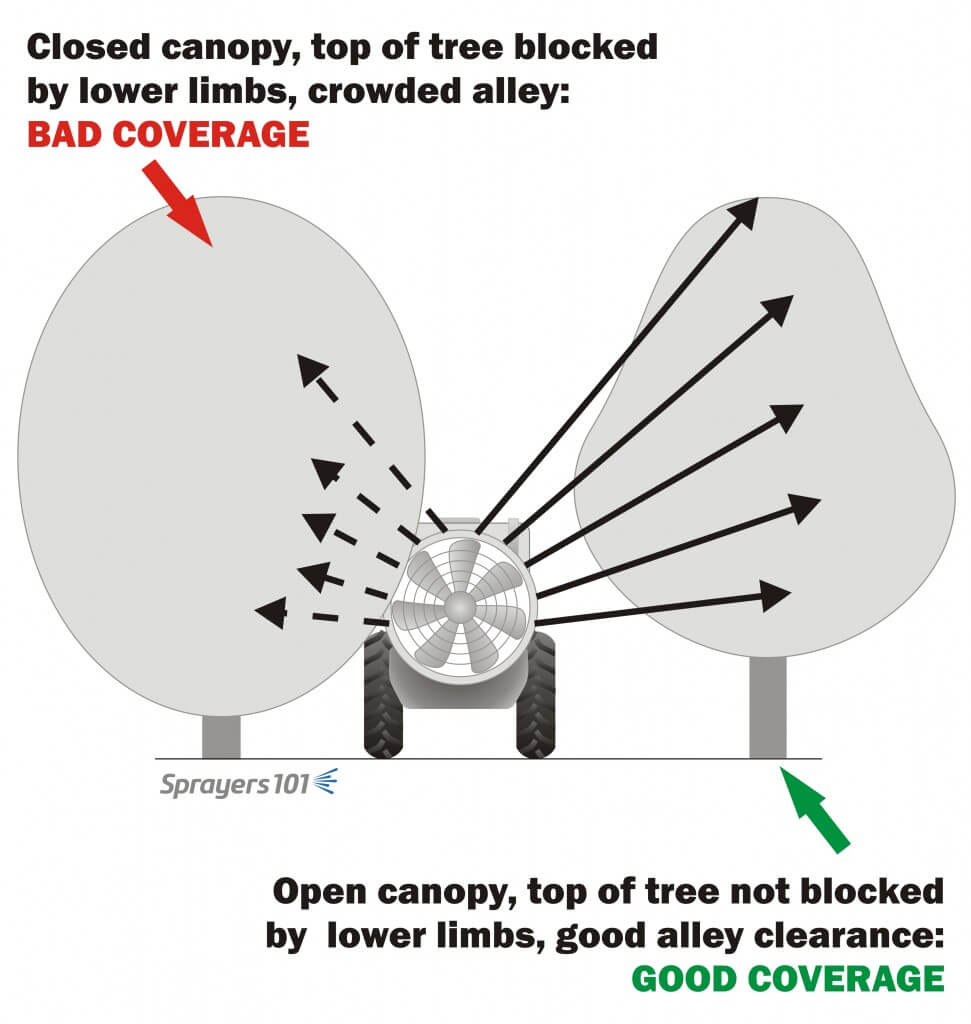

Of course, none of these adjustments had any great impact on coverage because the problem was that the alley had grown so tight that branches were brushing the cab of the tractor (see picture).

The canopy was so dense you couldn’t see the trunk! I asked the grower to move the sprayer down the row to a tree I saw that was far less dense that the others. We returned the sprayer to our original calibration settings and achieved excellent coverage once again. The only solution was to prune the trees, and once his workers did this, coverage improved considerably. An airblast sprayer can only do so much. Sometimes it comes down to canopy management.

Row Spacing in Specialty Crops

Canopy management isn’t just an orchard issue. For high bush blueberry crops, coverage problems may stem from insufficient pruning. How can spray reach the lower, inner portion of a mature bush to control spotted-wing drosophila if the canopy is too thick?

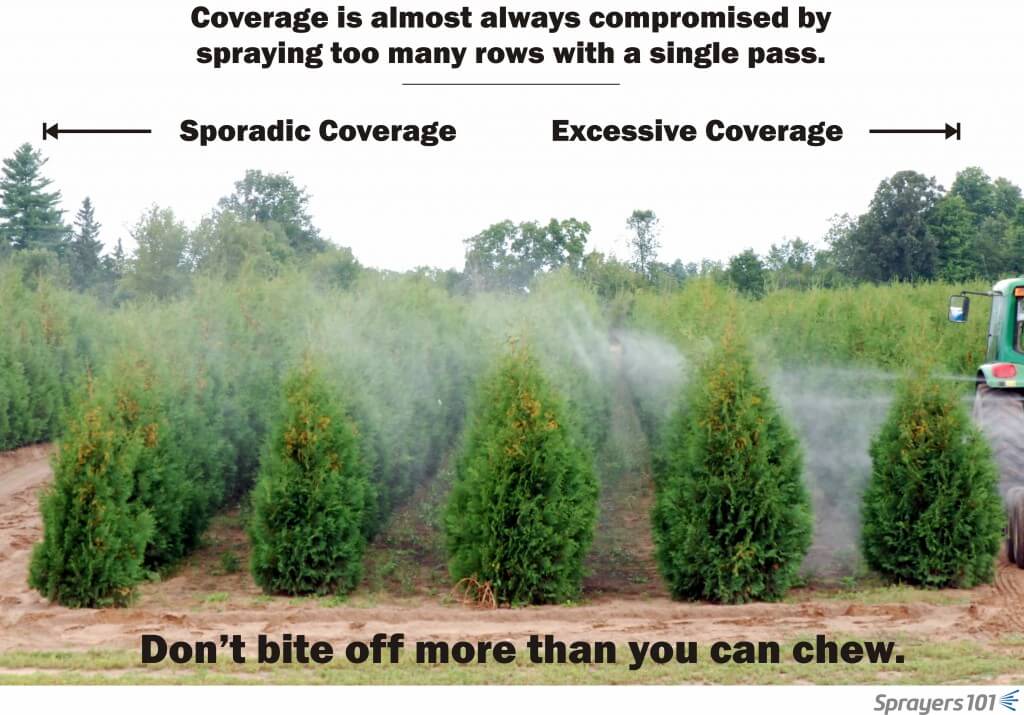

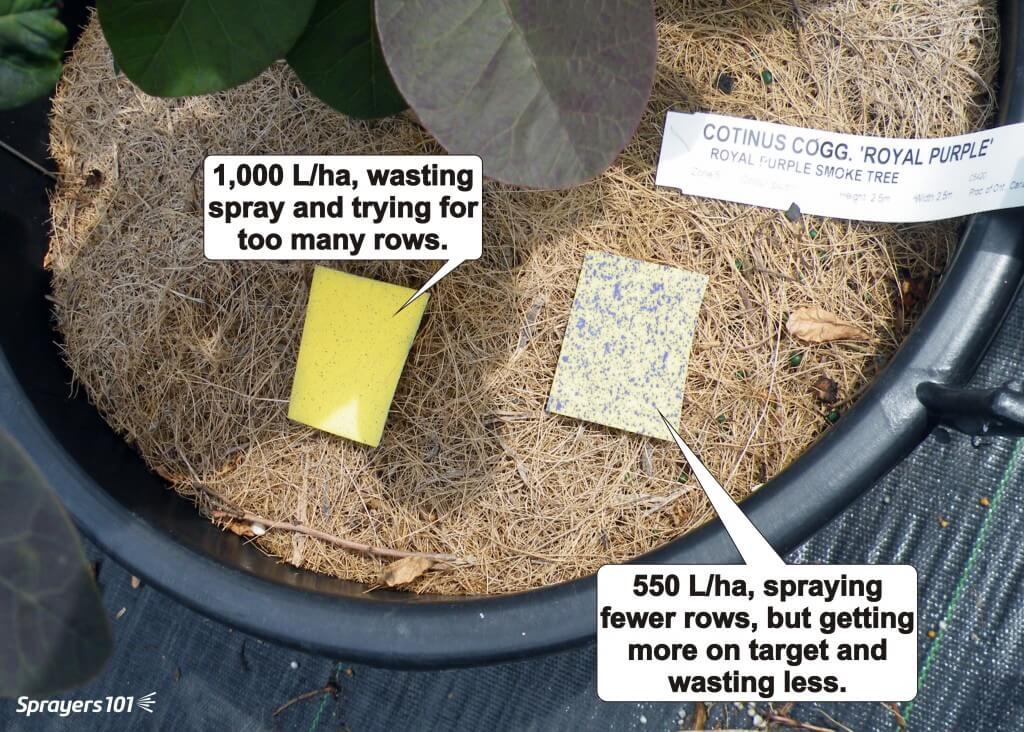

Sometimes it’s not the canopy, but the plant and/or row spacing. Many nurseries arrange container crops, shrubs, whips and cedars as tightly as possible. This may optimize how many plants will fit on a given area, but it compromises sprayer access (due to the reduced number of alleys) and may cause plants to block one another from the spray. Nursery sprayer operators often use cannon sprayers to throw spray over and through all those rows of plants, but cannon sprayers produce excessive coverage at the beginning of the swath and increasingly erratic coverage as a function of distance.

Coverage can be improved by reducing the distance the spray has to travel (i.e. leaving more alleys and reducing the density of planted rows).

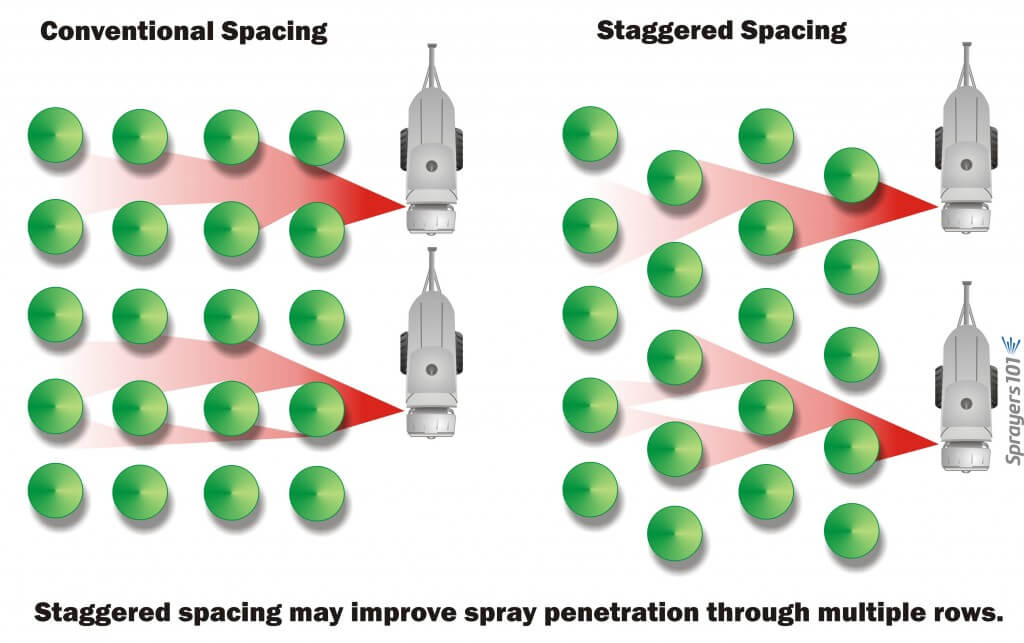

I also suspect that staggering plant spacing from row to row to reduce mutual shading might allow spray to penetrate more easily. As I write this, we’re planning to explore this concept in cedars.

In the end, try to see the spray target from the droplet’s point of view. If you can easily see where you want the spray to go, you’ll do well. If you can’t see the target, it’s far more challenging.