Spray application is one of the most important activities regularly done in any crop operation. It can also be one of the most expensive and time-consuming. Integrated Pest Management (IPM) is a multi-step process that helps sprayer operators make informed choices about when and what to spray. But, the decision to spray is not the end of the process.

The sprayer operator now faces a lot of decisions about sprayer set-up and application method. These decisions determine if the application will be effective, and they also determine if it will be efficient. Efficient spraying saves money and reduces environmental impact. The goal is to be both effective and efficient.

So what should the operator be aware of?

A quick Google search reveals a seemingly endless number of sprayer articles by government, industry and academia (and many on this website!). There are differences in definitions, opinions on priorities vary, and classic sprayer wisdom is sometimes supported and sometimes debunked by current research. But, if you read enough of them you will find more similarities than differences, and common themes will emerge.

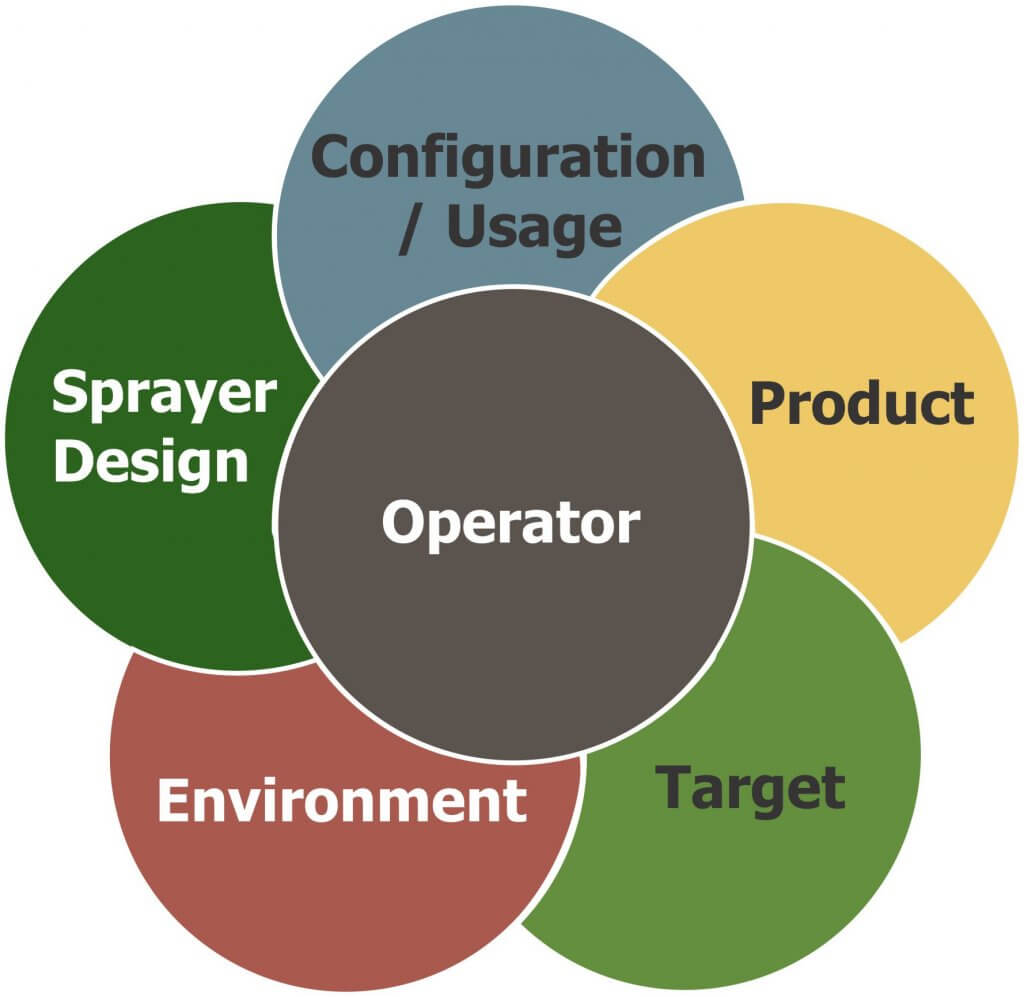

Most agree that the objective of spraying is the safe and timely delivery of an effective, uniform dose of product to a target area. Any product not deposited on the target (e.g. spray drift, sprayer leaks, run-off, etc.) reduces efficiency and is called wastage. The literature points to six broad elements that affect spray efficiency and effectiveness. Sprayer operators should actively consider all six elements before, and during, each spray application.

The six elements in the illustration overlap because changing one of the elements often means reconsidering others. For example, increasing droplet size to reduce drift potential also reduces the number of droplets sprayed. This may warrant higher spray volumes, which means you might require a more dilute tank-mix to maintain the rate-per-area. Only the sprayer operator’s decisions affect all the elements, which is why it’s pictured in the centre. Technology or technique can not compensate for an inattentive operator; an operator’s skill and willingness to do a good job impacts the overall efficiency and effectiveness of every spray application. Understanding how droplets behave (or misbehave) is essential.

Each element is comprised of many contributing factors. Some of these factors might fit under multiple elements and certainly we’ve reorganized this list many times over the years. No matter how they are presented, all of these factors (and more) contribute to the success of spray applications and they should figure into the operator’s considerations.

So, as sprayer operators, we should all be aware of how the factors that affect an application. Take an active role! Don’t be afraid to get out of the tractor and make changes to your pressure or your nozzle choice. Check your coverage as you spray, and make adjustments as the weather changes. Finally, recognize when it’s a waste of time and spray, and know when to pack it in. The days of “set it and forget it” are no more!