It’s time to spray and what’s the first thing you do? Check the weather forecast, of course. More often than not, the suitability of the weather is the main factor in the decision to spray. Let’s have a closer look at what each weather component contributes to the decision.

Wind:

Everyone knows that small droplets can drift if it’s windy, and the windier, the worse it is. But that’s hardly the whole story. Here’s how can we improve our understanding of wind and its impact.

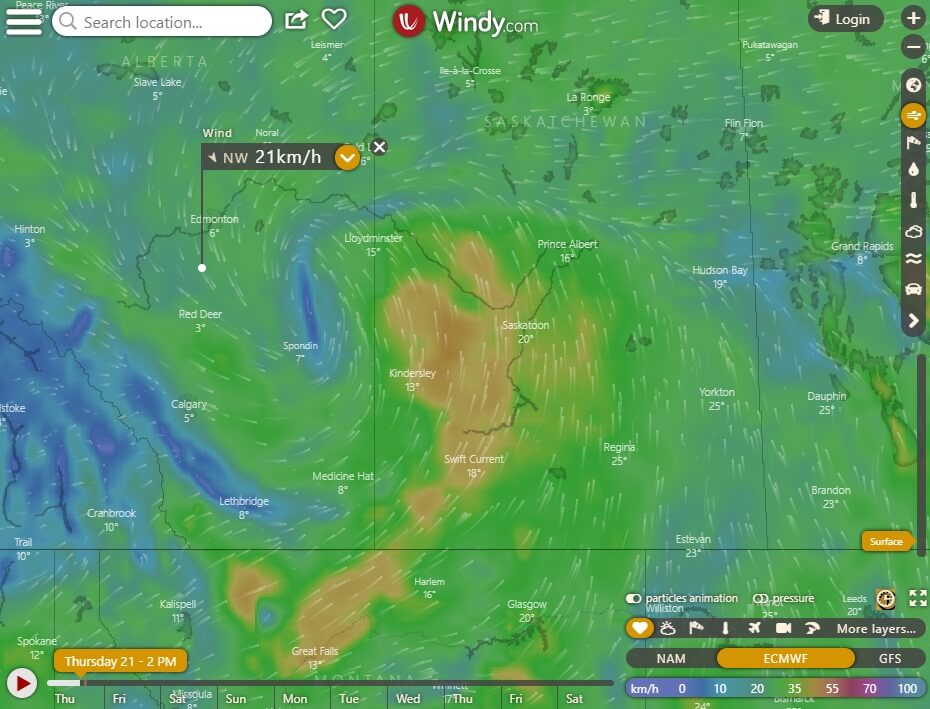

- Look beyond the wind forecast. It’s standard practice to look a day or two ahead for wind forecasts. At any instant, the wind speed and direction may be acceptable for our planned spray job, but we know that it will change. Consider wind speed sites such as Windfinder, Ventusky, or Windy for added insight. These services show trends over time in a great visual interface, allowing users to anticipate changes in wind speed and direction for better planning. While they aren’t forecasts per se, visualizing wind patterns over a larger region allows a better understanding of what’s coming your way.

- Use wind as an ally. We’re conditioned to think of wind as having a negative effect on spray drift. The less the better. Yes, droplet displacement increases with wind speed. But the “negative-only” perspective is being re-evaluated in light of dangers associated with wind-free conditions that often occur during temperature inversions (see “Temperature”, below). In fact, wind provides several advantages over calm conditions:

- Directional certainty. We can assess the risk to downwind sensitive areas. This is not possible with calm conditions because inversion air flow may follow terrain, and as inversions dissipate, the first daily winds can be changeable and unpredictable in direction.

- Turbulence. Wind creates mechanical turbulence which helps sprays deposit and disperse. Both of these effects have value. In a calm environment, such turbulent eddies don’t exist.

- Low drift options. If it’s windy, we have options to respond. We can lower the boom or lower the spray pressure. We can mix the next tank in higher water volume, forcing either a larger nozzle (larger flow rates of the same model nozzle usually produce coarser sprays) or slower travel speeds. All these practices reduce drift when it’s windy. In comparison, nothing (except not spraying) can be done to reduce risk during inversion conditions. This is because even low-drift spray contain enough fine droplets to cause damage if they linger.

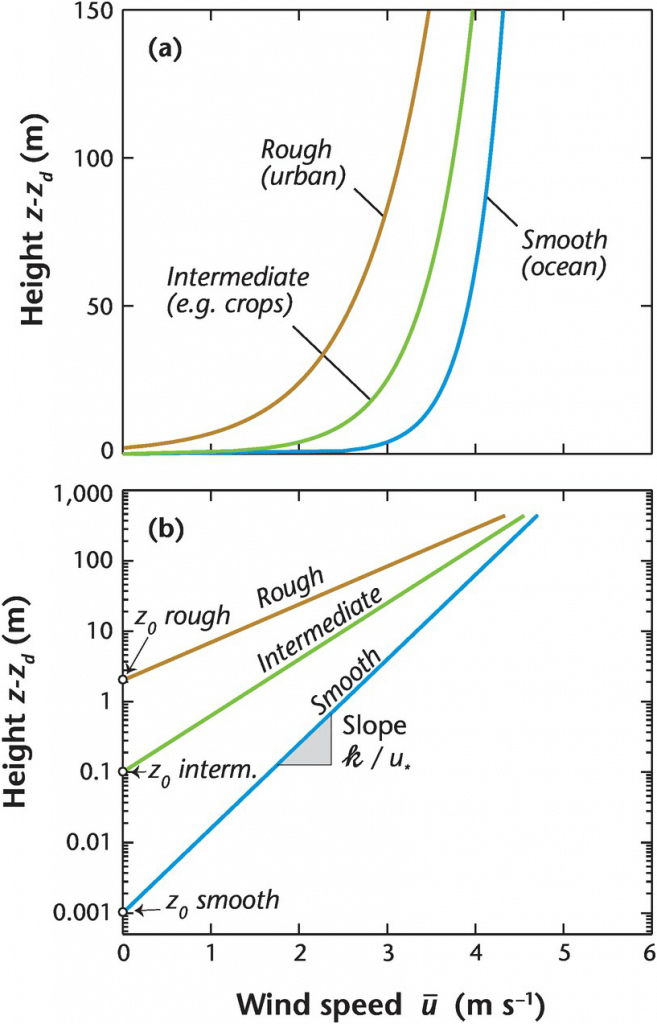

- Know your wind speed. The international standard for wind speed measurement is 10 m above ground level. When 25 km/h wind speeds are reported, they are at 10 m, not the 1 m height where the boom is located. Within the surface boundary layer, the part of the atmosphere closest to the ground, wind speeds typically increase linearly with the natural log of the height above the canopy. The slope of that line depends on atmospheric stability and roughness length. Very close to the ground, the wind speed reaches zero, and that height is a function of the roughness of the surrounding terrain.

As a rule of thumb, over a short crop canopy, expect the wind speed at 1 m above ground to be about 0.67x of the speed at 10 m. So if the weather reports 25 km/h, the actual wind speed at boom height is closer to 17 km/h. Remember that weather stations can be far away, and local conditions will vary. Always measure your local wind speed and direction with your own weather station or handheld device, and keep a record.

Wind and Mode of Action. Coarser sprays are a common way to reduce drift in windy conditions. But some modes of action aren’t well suited to coarser sprays. We can schedule our spray jobs throughout the day to correspond to spray quality tolerance. Apply the products that require the finest sprays (contact products, grassy herbicides, insecticides) when conditions are best, and save the sprays that tolerate the coarser sprays (systemic products, broadleaf targets) for less certain conditions later in the day. Or treat the fields whose downwind edges border a sensitive crop during better conditions. Here’s a rough guide to spray quality and herbicide mode of action.

Temperature

Like wind, air temperature is more complex than it appears at first sight. Here are some other aspects to consider:

- Understand temperature inversions. Temperature matters. But perhaps the most important aspect of temperature when it comes to spraying isn’t the temperature per se, but how it changes with height. The temperature change with height is used to identify dangerous temperature inversions.

Here’s how temperature profiles work (for a quick Sprayers101 overview, here, for the best in-depth explanation (NDSU), here): Due to atmospheric pressure, there is always a slight temperature decrease with height, about 1 ºC per 100 m (the dry adiabatic lapse rate). This temperature profile describes a “neutral” atmosphere, i.e., no thermal effects.

When it’s sunny, solar radiation heats the earth, which in turn warms the air near it. As a result, the rate of cooling with height is greater than the adiabatic lapse rate, and we have “unstable” conditions that are characterized by thermal turbulence (warm air rising, cold air falling) that actively mixes air parcels. Thermal turbulence is very good at dispersing anything in the air, including spray droplets.

When solar radiation is low or absent, the earth cools and this mostly affects the air near it. As a result, air temperature rises with height, and the daytime temperature / height profile is inverted. Air parcels no longer move up or down, in fact they return to their original location if displaced. This results in a “stable” atmosphere, also called an inversion.

Inversions are dangerous because they are associated with very low dispersion, and a spray cloud will remain concentrated and may linger over the ground for a long time, like ground fog.

Most weather services do not actively measure inversions. Instead, their presence has to be inferred by clues. For example, inversions:

(a) occur primarily when solar radiation is low, from early evening, overnight, to early morning;

(b) are more likely on clear nights, when soils cool more;

(c) can be seen when ground fog is present, or when dust hangs, moving slowly;

(d) are associated with low ground temperatures that also cause dew.

Recent findings about inversion in Missouri were summed up in this excellent webinar by Dr. Mandy Bish, Extension Weed Specialist at the University of Missouri. Her studies showed that inversions can begin hours before sunset, their presence and duration are dependent on local conditions such as topography and windbreaks, and recognition of telltale signs of inversions such as lack of windspeed are important for accurate local assessments.

- Use Mesonets if you have them. Mesonets are networks of weather stations, and they can add valuable information. For example, North Dakota has an extensive network of about 130 weather stations that, among other things, measures and reports temperature inversions. NDAWN (ndawn.ndsu.nodak.edu) reports temperatures at 3 m and 1 m, and issues warnings of temperature inversions as they develop at a specific location. NDAWN information is available as an app. North Dakota isn’t the only place to have a public mesonet, check to see what’s available in your area. The added information is worth subscribing to.

- Know the volatility of the product. Some pesticide active ingredients are volatile. This means they can evaporate from a wet or dry deposit during and after application (more here). Dicamba is a prominent example, but there are others, like trifluralin and ethalfluralin, 2,4-D and MCPA ester, and clomazone. Formulation can affect volatility, and the use of lower volatile esters of 2,4-D and better salts of dicamba have helped. Microencapsulation has been used to reduce the problem with clomazone. Volatility is strongly affected by surface temperature, and volatile products should not be sprayed on hot days or when the forecast calls for hot days following application. Volatile products have been found to evaporate from dry deposits for several days after application, and their vapours move under inversion conditions, causing widespread damage.

Sun

The sun plays a large role in spraying. Plants’ active growth improves herbicide translocation as well as activity in the photosystem, or in amino acid or fatty acid synthesis. The activity of herbicides has been shown to improve under sunny conditions for that reason.

Some herbicides, most notably diquat (Reglone), work too quickly when it’s sunny, and improved performance can be gained by spraying under cloudy or low-light conditions. The lack of photosynthesis allows for some passive translocation before the product causes tissue necrosis.

Sunny conditions also increase thermal turbulence we mentioned earlier, which is useful for burning off morning inversions. But what usually follows a sunny day is a strong inversion as the sun sets and the clear sky facilitates the earth’s rapid cooling. It would be possible to spray a bit later into the evening when it’s cloudy.

Humidity

Since about 99% of the spray volume is comprised of water, evaporation of this water can have strong effects on droplet behaviour. Droplets begin to evaporate as soon as they leave the nozzle, becoming smaller and more drift-prone while still in flight. Higher booms and finer sprays increase the flight-time of droplets, and this increases the sensitivity to evaporation.

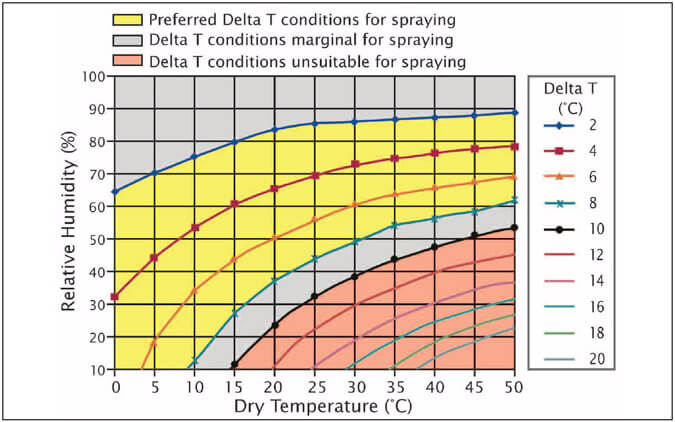

The most common measure of water in air is relative humidity (RH). RH doesn’t tell the whole story, though, because the same RH at different temperatures results in two different rates of water evaporation. A better measure is wet bulb depression. Wet bulb depression is defines as the difference in temperature reported by a dry bulb vs. a wet bulb thermometer. Wet bulb depression has more recently been coined as “Delta T” in Australia. The Delta T value is directly related to water evaporation, and charts have been published showing acceptable values for spraying. A Delta T of >10 ºC is considered too high.

After they deposit on a leaf, droplets can evaporate to dryness within seconds, and a dry atmosphere can result in rapid drying that reduces herbicide uptake. In one study, a Group 2 herbicide was applied to weeds in a normal sized spray, and also as a fine mist, both under very dry conditions. The normal spray showed the expected herbicide efficacy. The finely misted herbicide had no effect on the weeds, likely because the rapid drying prevented uptake. Interestingly, the product began to work again when the plants were later placed in a humid environment.

High humidity can also work against an application. Since humidity is often high during temperature inversions, droplets remain potent while they linger and drift over sensitive terrain. It would be better if they had evaporated and lost their effectiveness.

Some proponents of low water volumes and fine sprays have suggested oily formulations or adjuvants prevent evaporation. While this may slow evaporation, it also creates a dangerous condition in which many small droplets remain aloft and liquid for a long time, with high activity on any target they may encounter. The bottom line: Don’t spray low volumes with oily adjuvants.

The Perfect Day

We know that the ideal spray day is sunny, starts a few hours after sunrise once the dew has mostly burned off, and has consistent winds away from sensitive areas. Spraying should end well before before sunset, before calm conditions signal the onset of the inversion.

But what to do when that day never happens? All too often, high winds persist day after day, and night spraying is the only alternative. In that case, do what you can to minimize potential damage. Survey downwind areas. Choose cloudy skies that suppress inversions. Incoming weather systems are usually associated with consistent winds, and these may reduce inversion risk. If drift is a possibility, apply more water and use the coarser nozzles at your disposal to minimize it. Any investments made to boost productivity will pay dividends, allowing you to get a greater proportion of your work done when conditions are better.

Additional Resource

If you want an excellent resource for spray weather best practices, grab a free copy of Graeme Tepper’s “Weather Essentials for Pesticide Application” published by Australia’s GRDC.