Air-assisted boom sprayers have been around since the 70s. More common in Europe than North America, they have demonstrated value in mitigating drift and improving canopy penetration. The majority of air-assist systems are found on three-point-hitch or trailed sprayers, which is fine (and perhaps even preferable) as long as clearance, travel speed and acreage aren’t limiting factors. In North America, trailed air-assist sprayers are used by some vegetable and strawberry growers, but air-assist in general is rare among field croppers. There are a few possible reasons for this:

- North American field croppers are predominantly concerned with work rate and prefer the larger, faster, self-propelled option.

- Air-assist is not ideal for herbicide applications to bare soil because unless it’s perfectly adjusted, it tends to bounce spray off the ground. A canopy is preferred to capture the spray and exhaust the air energy. This reduces the overall utility of air-assist.

- The air-assist feature is expensive and growers are either unaware or unconvinced of its value.

- There are few, if any, after-market air-assist upgrade kits available. This is because installations are bespoke; The apparatus is heavy, adds load to existing electrical and hydraulic systems and can interfere with boom folding. So, getting air-assist means purchasing a new (and perhaps unfamiliar) brand of self-propelled sprayer… and there aren’t many on offer.

Air assist booms came to Western Canada in the early 1980s in the form of the “Spray-Foil” sprayer, later renamed Spray-Air. This sprayer was developed and manufactured in Carseland, Alberta. It used a shear-atomizer nozzle, a “foil”, that required a strong airblast to properly atomize a liquid feed that was introduced on the foil’s leading edge. As a result, it created a powerful airblast and a very fine spray. It was marketed as a way to reduce herbicide rates, an attractive feature during the times of drought, high interest rates, low commodity prices, and general economic malaise of farming on the prairies during the 1980s. Neighbours of Spray-Foils didn’t like the drift potential of the machines, and chemical companies objected to the claims of reduced water volumes (2 gpa) and lower product rates which contravened label directions. An unflattering test report of the sprayer by PAMI in Lethbridge resulted in a protracted lawsuit which helped cast the fate of the company. A Danish company licensed the design and sold it in Europe under the name Danfoil, where it continues to exist and @Nozzle_Guy saw it in person during the 2019 Agritechnica.

Eventually, Spray-Air rose from litigation and developed an improved nozzle with the assistance of the National Research Council (the “Shear Guard”) and introduced the Trident boom which gave users the option of atomizing spray with a conventional boom with or without air assistance, in addition the the native choice of shear-atomization. The sprayer chassis itself also continued to improve with a better overall design. Nonetheless, it was sold to Miller in the 2000s after a period of sales stagnation.

A fundamental problem with shear-atomization on sprayers like the Spray-Air is the requirement for significant air velocity for the atomization to occur properly. When the canopy cannot absorb that energy, air rebounds and creates drift. And if the operator cannot reduce the airblast strength without adversely affecting atomization, it leads to problems.

This photo (Figure 9) was submitted by Mr. L. Jones, a cash-cropper in ND, USA. It’s his JD4710 (circa 2004), which has 100′ booms and an 800 gallon tank. What’s interesting is that it has a Miller’s Spray-Air. This air-assist system is available on Miller’s Nitro and Condor line as well as New Holland sprayers (which are built by Miller). @spray_guy did some work with it on a Condor in field corn. It comes with their dual-flow nozzle system (Shear Guard™ PLUS Air Nozzles plus Dial-A-Drop™) for fungicides (applied at low volume) but you can also use conventional tips for coarser herbicide work.

Mr. Jones says they use the flat fans when spraying a soil-applied herbicide. If it’s moderately windy, they engage the air to reduce drift. When they apply fungicide on wheat they use only enough air to move the heads as they pass over. Bystanders can see the spray enter the canopy and a portion rebounds, which they suggest (and hope) provides some underside coverage. That’s possible, but it’s generally better to keep all the spray in the canopy. This can be achieved by further reducing air speed, increasing travel speed, and/or aiming the air slightly backwards to increase the cross-sectional distance the spray has to travel and slow the spray velocity relative to the sprayer speed.

Generally, we’re proponents of using air when spraying. It opens the crop canopy, exposes otherwise-hidden surfaces, entrains and carries droplets to the target (reducing drift and improving coverage) and it extends the spray window by out-competing moderate winds. We have no proof, but wonder if it might also help alleviate the negative impact of tire and chassis turbulence on coverage uniformity under the boom. And, before you feel we’ve ignored a big benefit, we’d would be very cautious about using air-assist as a means for reducing carrier volume. The debate about finer sprays at less volume giving greater efficacy continues. While true at times, any benefit needs to be balanced with the downsides of potentially more drift and evaporation.

Here’s some 2018 footage from an assessment of canopy penetration in field pea using a Miller Nitro with Spray-Air. We see coverage extends deeply into the canopy, the degree of which shares an inverse relationship with depth (fairly classic). Note the heterogeneous mix of smaller and larger deposits from the air-shear nozzles. While some heterogeneity is good, this extreme span represents waste. The product tied up in the largest droplets could have been more gainfully employed as several smaller droplets. This pattern may be the result of using insufficient air energy, preventing the air-shear nozzle from fully atomizing the spray liquid.

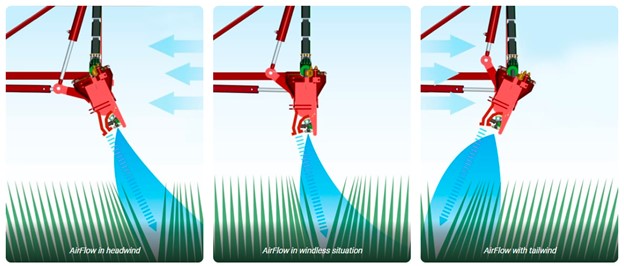

In 2015 we felt air-assist needed some exposure, so we held a demonstration at Canada’s Outdoor Farm Show. Over three days we used water-sensitive paper to evaluate coverage in a soybean canopy (moderately dense, planted on seven inch centres) from a Hardi Commander (Figure 10) with and without air-assistance. We originally wanted to get our hands on a self-propelled Hardi Alpha Evo (Figure 11), but there were only two in North America at the time and neither were available. By the way, the Alpha Evo is now on the third iteration, but still uses the Twin Force air-assist system which allows the operator to change the angle of the air and the air speed. Each blower can be steplessly adjusted to a maximum output of 2,000 m³/h per m of boom and a maximum (and we’d wager, often excessive) air speed of 35 m/sec. You can watch a video explaining how to dial-in a Twin Force sprayer here.

The demo treatments

The sprayer was calibrated for 93.5 L/ha (10 gpa) at 2.75 bar (40 psi) at 9.7 km/h (6 mph). The boom was suspended 50 cm (20 inches) above the top of the canopy. On one side of the boom, we ran yellow mini drift nozzles (MD 11002’s) to create a Coarse spray quality, and on the other side we ran conventional yellow flat fans (F 11002’s) to produce a Fine spray quality.

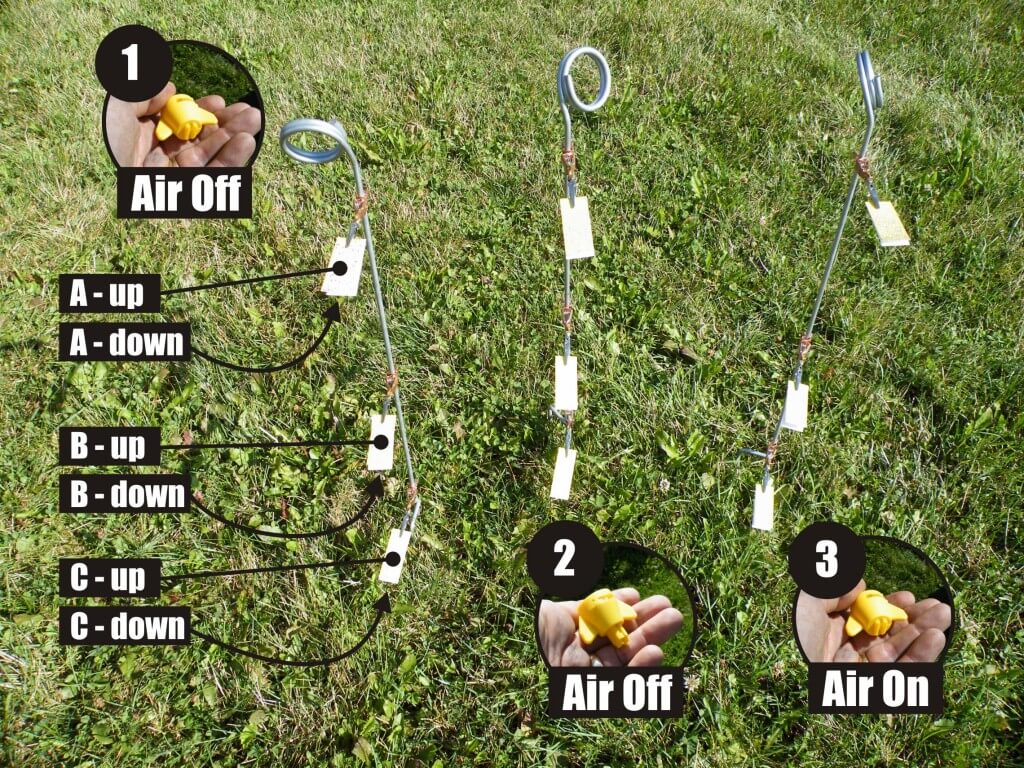

Water-sensitive paper was attached to rods at three canopy depths: at the top, midway down and at the bottom of the canopy. Papers were oriented both face-up and face-down (Figure 13). Following each application, papers were collected for digital analysis using “DepositScan” which calculates the percent surface coverage and the deposit density. Both of these factors contribute to overall coverage.

We collected papers from three treatments:

- Fine spray quality, No air assist

- Coarse spray quality, No air assist

- Fine spray quality, Air assist

We held two demos per day at noon and 3:00 pm for three days, giving us six sets of papers to analyze for each treatment. The weather ranged from 25-29°C, 30-58% relative humidity and winds of variable direction from 3-11 km/h.

This was a simple randomized complete block design, but it was not a rigorous experiment. We simply took the opportunity to gather numbers from the demonstration. A more fulsome experiment would require many, many more passes under more stable conditions. For example, we set the angle of the air and nozzles to about 30° forward and the air speed at maximum, which wasn’t necessarily correct. Ideally, these settings should have been fine-tuned to match the forward speed of the sprayer, the density of the crop and the weather conditions. There was a lot of boom sway (watch the video below).

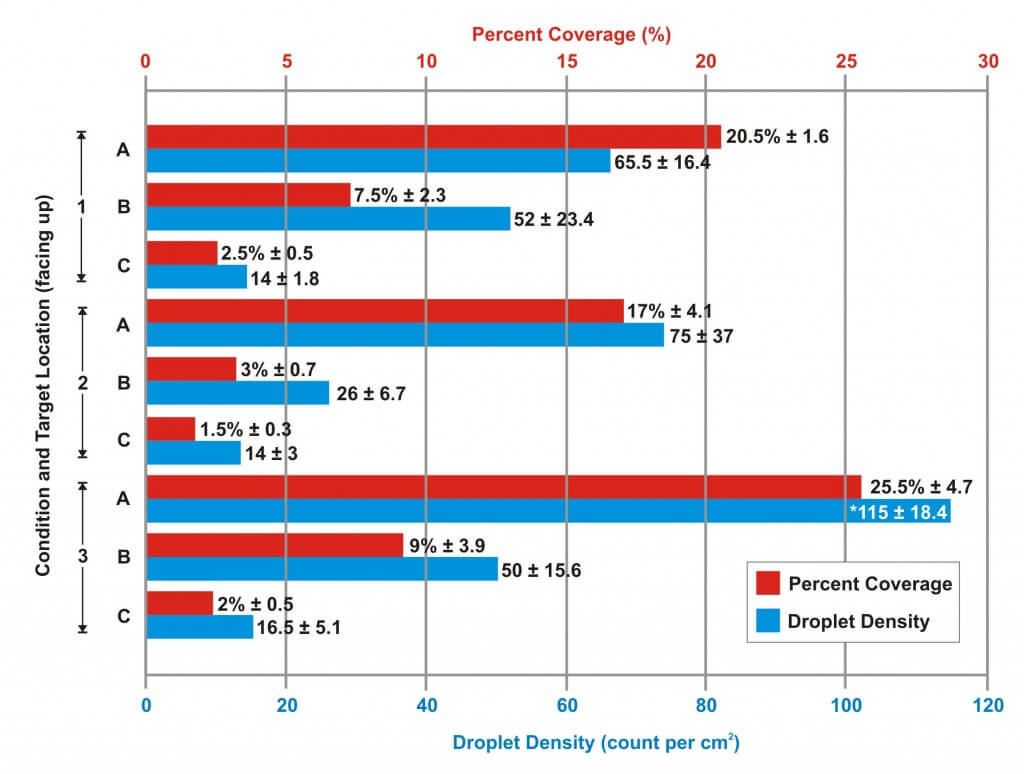

And so, caveats aside, the following graph illustrates the mean percent coverage and mean deposit density for papers in each treatment, for papers that were facing up (Figure 14). Standard error of the mean is presented alongside the average (x% ± y).

Results

Treatment 1 (Fine, No Air) reflects a typical coverage pattern for a dense canopy. Coverage declines as a function of canopy depth because spray droplets are intercepted by plant material before they reach the ground. This is particularly evident with broadleaf canopies that create shading. The coverage data doesn’t show it, but there was an obvious (and unacceptable) plume of spray drift during these applications (see Figure 15).

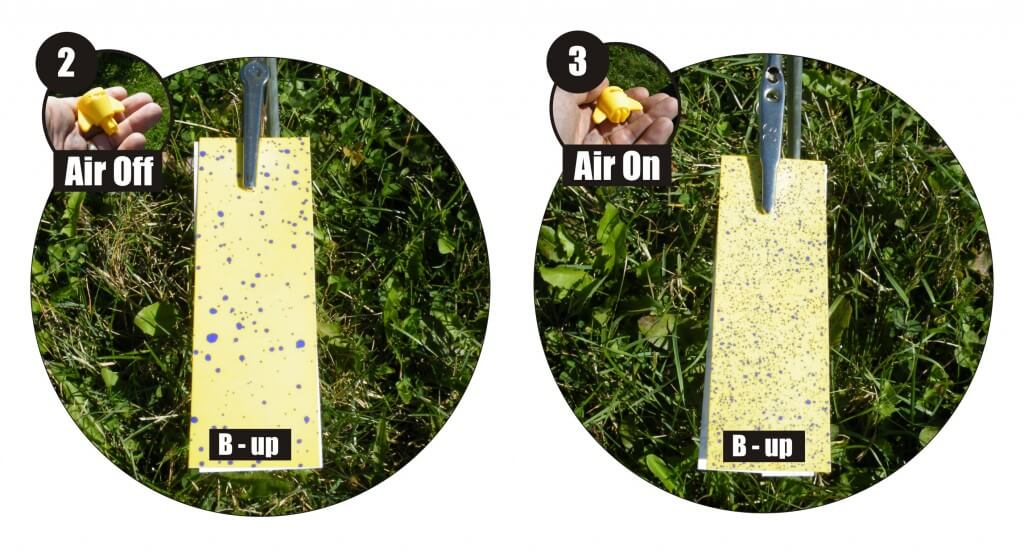

Treatment 2 (Coarse, No Air) follows the same coverage trend as Treatment 1. This treatment represents much larger, and fewer, droplets than Treatment 1, and yet the only obvious difference is reduced coverage in the middle of the canopy. There was little or no plume of spray drift during these applications.

Treatment 3 (Fine, Air) also followed the trend of reduced coverage as a function of canopy depth. Mean coverage was higher at the top of the canopy compared to the other two treatments. In fact, according to an ANOVA, deposit density was significantly higher in this canopy position than the other treatments, with 95% confidence. While mean coverage in the middle of the canopy was more than 2x that of Treatment 2, it was not statistically significant. There was no apparent difference at the bottom of the canopy. It is important to note that unlike Treatment 1, there was little or no spray drift plume during these applications.

DepositScan was unable to detect coverage on any of the downward-facing papers. However, close visual inspection did reveal differences. Unsurprisingly, Treatment 2 (Coarse, No air) did not produce any underside coverage; Large droplets do not change direction mid-flight unless acted upon by some other force. Droplets can bounce and shatter, but that did not occur here. The Medium-Fine droplets created in Treatment 1 (Fine, No Air) and Treatment 3 (Fine, Air) did leave trace coverage on the downward-facing surfaces. Generally no more than 10-30 deposits on the entire 1 x 3″ surface, representing less than 1% total surface coverage. It could not be determined if the air used in Treatment 3 improved underside coverage over that of Treatment 1.

Did air assist make a difference?

Let’s start with the literature. Many experiments in peer-reviewed journals show that it does. A perfunctory literature review reveals improved coverage in the middle and lower portions of cotton, potato, soybean and wheat canopies. Some of these experiments were based on coverage using fluorescent dyes, and some with water-sensitive paper. Others were based on efficacy and report improved crop protection. The actual implementation was highly variable with some authors recommending angling the air and nozzles forward 20-25°. Others proposed 30° backwards. Most agreed (as do I) that the air speed should be set relative to the canopy density where higher speeds improved coverage deeper in the canopy, but did so at the expense of coverage in the higher canopy. Picture a bell curve on it’s side where the Y axis is canopy depth and the X axis is coverage; More air shifts the peak of the curve down the Y axis, into the canopy.

As for our demonstration, some interpretation is required. If an operator is spraying a contact product with limited or no translocative properties, then coverage becomes especially important. In order to improve coverage, higher volumes and finer droplets combined with slower travel speeds are often advised. This may be impractical, as most operators prefer to use less water and drive faster.

When we used Medium-Fine droplets with no air assist, coverage was good (Figure 14) and better than coverage obtained using Very Coarse droplets. However, spray drift was unacceptable (Figure 15). When air-assist was engaged, we reaped the coverage advantage of smaller droplets and drift reduction as good or better than what we saw with coarser droplets. Unexpectedly, we did not see an obvious improvement in coverage from the air assist. This begs the question “If the spray didn’t drift, where did it go?” This demo was a far cry from a formal mass accounting exercise, but my guess is it wasn’t effectively captured by our collectors and that a hefty fraction ended up on the ground. We would expect more uniform coverage under the boom, and some improvement in canopy penetration, but our ad hoc experiment wasn’t sophisticated enough to reveal it.

In the end, we feel there are advantages to the air-assist mechanism. The ability to employ a finer spray quality when required, while greatly reducing spray drift and combating inclement weather to extend the spray window are appealing features. Research has clearly demonstrated that deep-canopy spray coverage and overall efficacy are improved when this system is properly adjusted to match spray conditions. We’re not comfortable with suggesting it warrants lower carrier volumes (i.e. not dose) because of the expertise required to adjust the system. However, to be fair, experienced operators have accomplished it

We hope to see more air-assist options on boom sprayers.