Did you come here looking for advice on which sprayer is best for your small operation? Are you looking to ditch the backpack mist blower? Do you want to avoid repeatedly mounting and dismounting a 3-pt hitch sprayer from your only tractor? Are you concerned you’ll have to sell an organ to be able to afford one? We hear you, and we’ll try to help. Let’s set the stage with a few facts.

Airblast sprayers stay in service for a long time; more than twenty five years is not unheard of. The majority of them are the generalist, PTO-driven low profile radial design with capacities ranging 150 to 1,200 gallons. Typical fan diameters are around 30″ and can produce >40,000 m3/h of air, making them a good fit for most pomme, citrus and tender fruit canopies. These sprayers come with a horsepower price tag of perhaps 45 hp or more. Many of these sprayers eventually enter the used sprayer market, making them an affordable option for small acreage specialty operations. But, affordability should not be the sole motivation when choosing a sprayer.

The key to optimizing sprayer performance is to match the air settings to the the canopy you’re trying to spray. You can start reading about the process here. In the case of small and medium-sized canopies like vine, cane and bush crops, the fleet of gently-used sprayers we just described tend to produce too much air. There are options to improve the fit, like driving faster to reduce dwell time, or perhaps the operator can employ the Gear-up Throttle-down method. But, the best plan is to employ a smaller sprayer, which produces a more appropriate air volume, has a smaller profile, delivers better fuel efficiency and won’t break the bank.

So, where are these sprayers? Unfortunately there aren’t many, and options are especially limited if you don’t own a tractor to power them.

We encountered a good solution in June, 2014, when we were invited to Durocher Farm in New Hampshire to see their new airblast sprayer. In years previous, spotted-wing drosophila (SWD) was a significant pest in this two acre, high bush blueberry planting. They claimed that since buying their new sprayer they no longer had any trouble with SWD. That’s quite an endorsement!

I’m not sure what I expected, but I was captivated by this miniature orchard sprayer. The toy-like size carried a zero-intimidation factor and I immediately wanted to start using it. Italian-made, Carrarospray’s hobby line is designed to be pulled behind vehicles without PTO. The ATVM is available in capacities from 120-400 L. The one I saw had a 400 L capacity, adjustable air deflectors, a fan speed gear box, and it was powered by a quiet and efficient pull-start Briggs & Stratton four-stroke engine. It even had a trash guard, a kick-stand and a clean water tank for hand washing. That’s a lot of features.

Thanks to Kitt Plummer (Durocher Farm), Penn State, Univ. New Hampshire and Chazzbo Media for filming these 2014 videos:

The sprayer was pulled (in this case) by a mower, so the grower not only sprayed, but mowed his alleys at the same time. It fit beautifully between the bushes, so the potential for physical damage to the berries was minimized. The air speed and volume was enough to displace the air in the blueberry canopy and replace it with spray-laden air with minimal blow-through. Combined with an appropriate spray volume and distribution over the boom, we found that the coverage it provided was excellent.

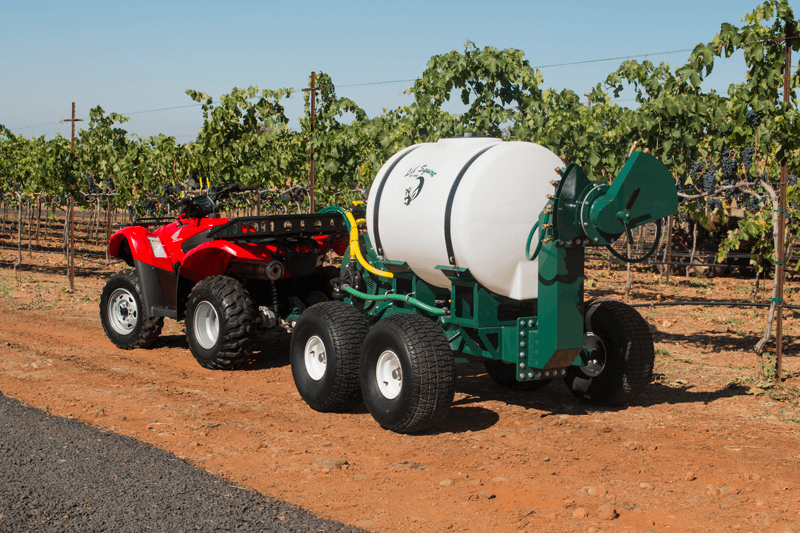

Since seeing this sprayer, we have had reports that importing it to Canada has proved challenging. But there are alternatives. A few companies here in North America offer economy-sized airblast models that are ATV trailed, or skid-mounted, or attached to a small tractor via a three point hitch. PBM’s Lil Squirt is a simple and versatile option. Available primarily in the western US from California through to Washington.

Another option is the mounted, PTO-driven mistblower line from Big John Manufacturing in Nebraska.

Or MM Sprayer‘s ATV sprayers, which come PTO or Engine-driven. The LG400 has a 106 gallon tank and a 20″ fan. I’d like to see deflectors, but you could easily add them. Here’s a 2024 pdf on features.

Or Wisconsin’s Contree Sprayer and Equipment. They carry the “Terminator” line. Skid mounted, one-sided air shear units with capacities from 15 to 100 gallons, this company offers a range of possibilities both PTO and gas-driven. Well worth a look.

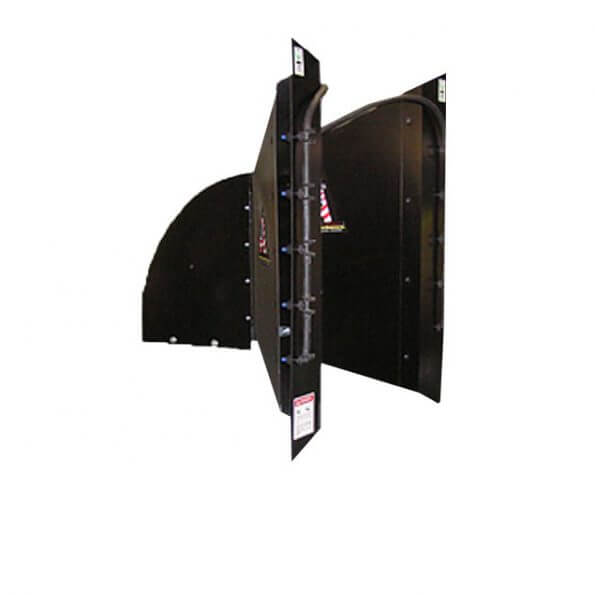

Then there’s the A1 Mist sprayer series, also out of Nebraska. They carry the Terminator line as well as an interesting two-sided volute option that employs conventional nozzles and allows one pass down an alley rather than two. This is a big productivity booster:

Then there are larger, PTO-driven, three-point hitch options. In fact, there are many options for this manner of sprayer, but they tend to be out of the price range for small operations, and they do require a tractor. That isn’t a deal-breaker, though, as they can sometimes be found used. Pictured below is British Columbia’s Major 193 (Slimline Manufacturing) and a Brazilian-made option (Jacto) distributed out of Quebec.

When considering your options, give serious thought to your work rate, refill time and other factors that go into developing a robust spraying strategy. What’s a spraying strategy? That’s a farm’s overall management and operational plan for achieving safe, effective and efficient spray coverage. You can read more in chapter 8 of Airblast101, which you can download for free, here. And, just to play Devil’s Advocate, go small but not so small that the sprayer is underpowered.

We staged this video in 2011 (spraying only water, so don’t mind the lack of PPE) to show how a sprayer can be too small for an operation. This 3-pt hitch GB cannot overcome the cross wind and the spray barely reaches the apple trees. Reducing travel speed and increasing pressure won’t cut it, either.

Of course, other possibilities are emerging for crop protection in small acreage perennial crops. Multirotor drones are capable of delivering air-assisted spray from above the canopy. While it’s still a drift-prone and inconsistent means for broadcast spraying, it might lend itself to perennial row crops. Equipment design is evolving quickly and global research is underway to establish best practices. As regulators and agrichemical companies focus more on this method we may see drones as a cheap alternative to a tractor/airblast sprayer, with no compaction, no mechanical damage to fruit/berries, and no potential for splashing infection throughout an operations.

Even further into the future, small autonomous sprayers may be viable, too. Very much in their early days there is great potential. One example is the XAG Revospray Ground 2 with it’s 150L capacity or the R150 with it’s 100 L capacity.

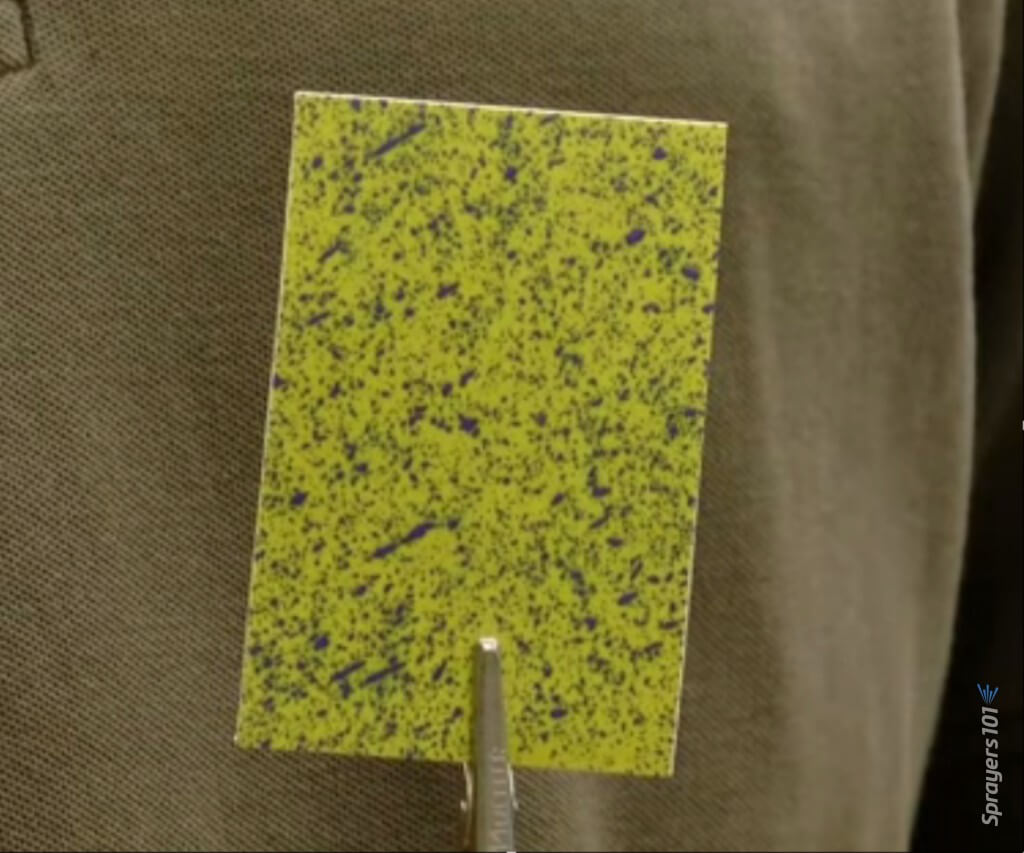

It’s early days, but there are researchers looking at the spray pattern from these units. The image below may not be a fair indication because the nozzle used may not have produced as wide a swath as possible. Thanks to Dr. M. Reinke for the image.

And recently, small autonomous platforms have become more common. Perhaps there’s an opportunity to place a gas powered sprayer on these platforms, or use them to pull a hitch-style sprayer. One such possibility is created by the Burro, shown below at the Ontario Fruit and Vegetable Convention in 2024.

Are you aware of a sprayer that’s not in this article? Let us know! Good luck and make sure you have only slightly more “sprayer” than you need.