I always await a trade show with excitement. Everyone’s going to be there, showing their latest and greatest. You see old friends. And of course, trade-show food. Every year, I search for the Fiddle Sticks I learned to love in the 80s. They’ve been replaced by the Pocket Dawg, it seems. Not the same.

Touring around the sprayer and nozzle displays at this year’s Western Canada Farm Progress Show, I couldn’t help but notice that an old contrast got even more striking.

As expected, sprayers are bigger and heavier than ever. The JD r4045 is an example, weighing in at 36,000 lbs, with a list of $563 k CDN. It’s not the only one, though, I just pick on John Deere because they can take it. They know it’s outrageous.

Most sprayers are made by multinationals, with large engineering budgets, and they build complicated and sophisticated machines. They’re huge. They crush weeds. Their cost has often increased by double digits annually.

Then it’s off to the nozzle manufacturers, for the contrast. Small booths nestled among other family businesses, staffed by the owners. Yes, most of the nozzles we use are produced by surprisingly small family-owned companies with just a handful of employees. They make their products on-shore. They have modest research budgets. They collaborate with each other and share components. And their products are priced very low. Not bad, considering the nozzle is the most important part of the sprayer (after the operator, of course).

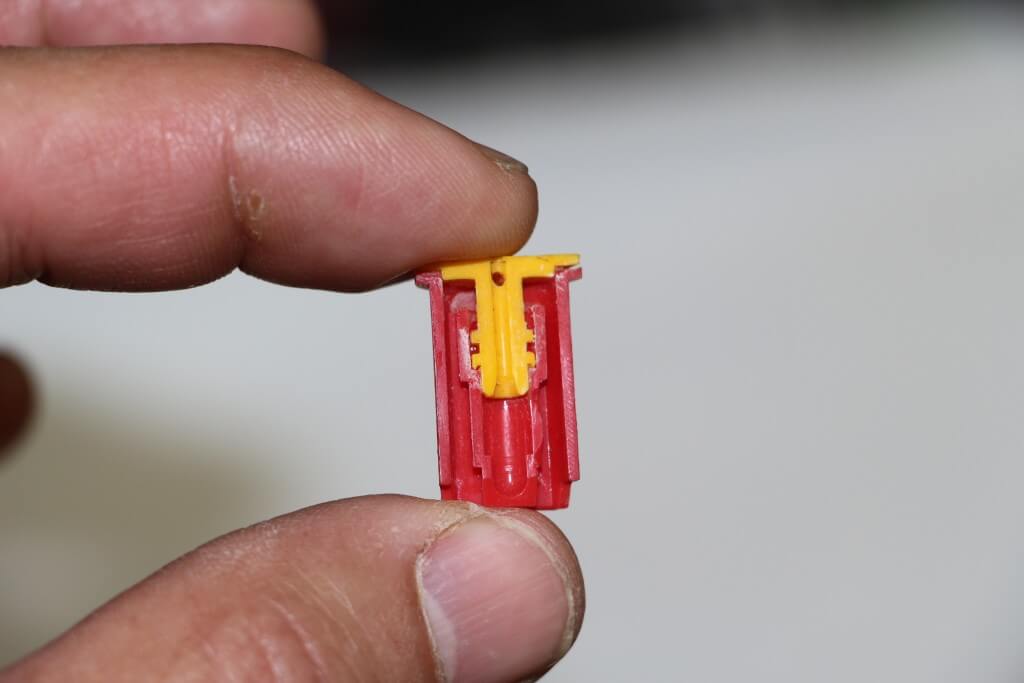

One can get a very good low-drift, air-induction nozzle for about $6.00. That’s close to the same price it was 10 years ago. Nozzles, engineered to remove small droplets with a two-stage venturi design offer good spray patterns between about 30 and 100+ psi. This means that a $450,000 sprayer with a 120 foot (36 m) boom requiring 72 nozzles can be outfitted with nozzles for a cost of $450 (0.1% of the sprayer cost) , or $1350 for a set of three.

These nozzles have important tasks. They need to:

- meter the pesticide mixture out accurately (within 5% or less of the target amount);

- atomize the mixture into droplets that maximize coverage while minimizing drift and other waste

- distribute the spray uniformly across the width of the boom.

If nozzles miss on any one of these goals, producers pay with lower control, higher costs, or environmental contamination. So these little devices are important.

We do see innovation in this important area, again from small companies. Devices designed to improve rate control (pulse-width modulation or variable rate nozzles), to reduce drift (PatternMaster), or to improve canopy penetration while increasing coverage and reducing drift (Wingssprayer) are appearing. While these aren’t cheap, they cost a fraction of what the sprayer costs, are light, and reliable.

And they’re meeting with resistance because of a very peculiar response. Over the past 15 years, when a producer has heard the cost of a new sprayer, the sticker shock has made them walk away. But not far. They’ve returned shortly after to make the purchase. Need a new sprayer, right? Need high clearance, hydrostatics, air-ride, horsepower.

But when they see the cost of even the most expensive atomization system (some as low as $4000, the most costly typically $20,000 to $40,000), they just shake their heads and walk away. Probably for good.

And yet it is this purchase that will probably pay the highest dividends. It’s this technology that can answer to the needs presented by heavy, fast tractor units. The $6.00 nozzle is out of its depths here. And the innovators need the sales so they can conduct proper research to give you the best value, and lower their costs.

A New Process

How about we look at it this way: Budget for a new sprayer. Say you accept that it will cost about $440,000. This is the total amount you will spend. Now budget for a great delivery or atomization system. One that either improves coverage, decreases drift, improves consistency, or makes you more productive. Let’s go for the best one, and budget $40,000.

Now don’t raise the cost of the investment by that amount, but instead make it inclusive. The sprayer’s tractor unit budget is reduced to $400,000 to accommodate the atomization system, for a total cost of $440 k, still within budget. You may need to re-evaluate the type of sprayer, or features, that you will be able to obtain with a 10% lower cost.

Or perhaps you can take advantage in the slightly more desperate market situation for big iron and score a better deal. Buy used, or invest in your old sprayer to rehabilitate it.

Either way, we need to start thinking differently. Within any given budget, let’s purchase the most important components first. Then let’s put wheels on it. And then, let’s get some Fiddle Sticks.