In early July 2016, a farm supplier contacted us on behalf of a client with a history of disease control issues in his field pepper operation. He wanted us to calibrate their sprayer and diagnose spray coverage to see if there was room for improvement. Improved coverage doesn’t necessarily mean improved efficacy, but generally it’s a reliable indicator. When we arrived at the field the winds were gusting over 15 km/h, which had the potential to create a massive drift issue. We were only spraying water, so it was decided that if we managed decent coverage in those conditions, there would be no need to worry on an acceptable spray day.

The grower traditionally ran two different settings on his sprayer. They were relatively low volumes for a vegetable operation, but the crop was still small at this stage, so we did not propose raising the volume:

- TeeJet AITX 11008’s on 50 cm (20″) centres at 11.25 kmh (7 mph) and 3.44 bar (50 psi). That’s 3.35 L/min (0.89 gpm) per nozzle for a total rate of 350 L/ha (37.5 gpa).

- TeeJet ConeJet TXVK18’s on 50 cm (20″) centres at 7 kmh (4.5 mph) and 3.44 bar (80 psi). That’s 1.6 L/min (0.42 gpm) per nozzle for a total rate of 275 L/ha (29.5 gpa).

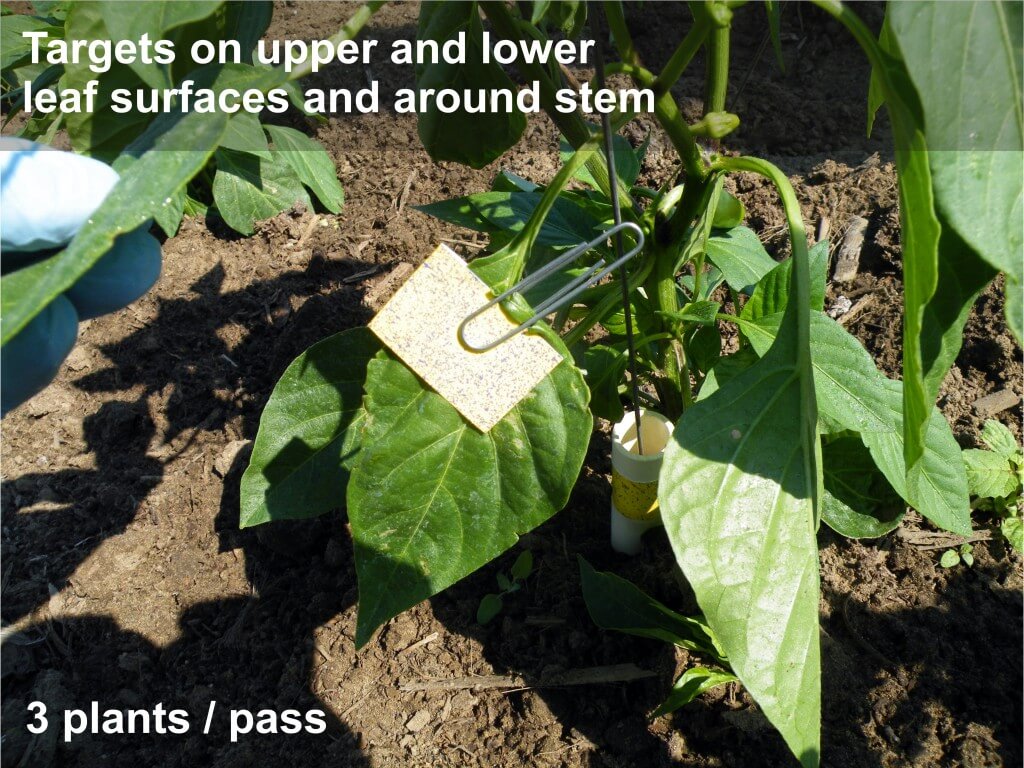

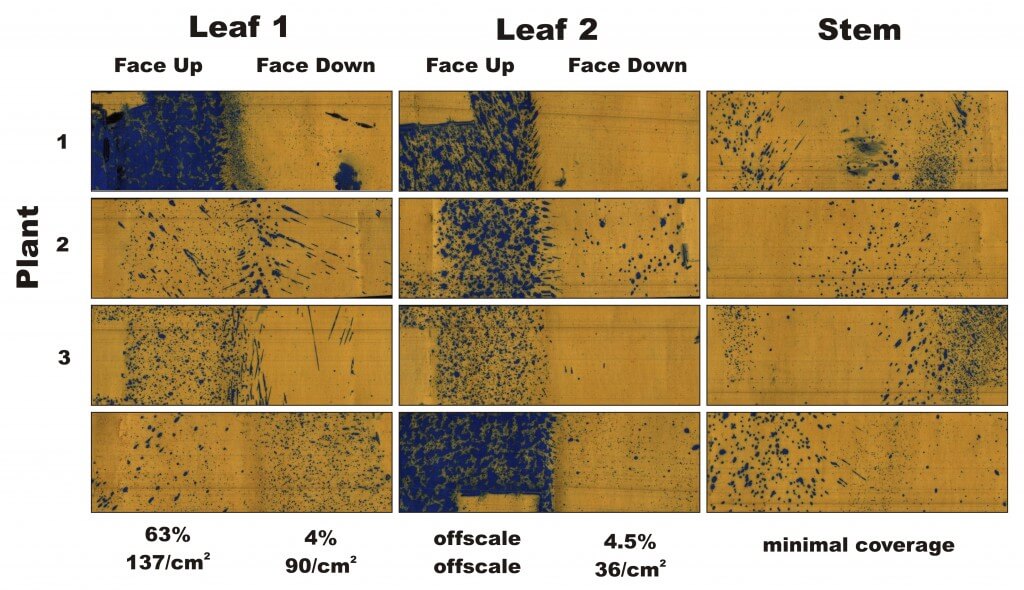

To test the coverage with these settings, we folded a piece of water-sensitive paper over a leaf to cover both surfaces, and wrapped one around a hollow tube to mimic a plant stem (see figure). Three plants were papered for each sprayer pass. Papers were collected, digitized and analysed for percent-coverage and droplet density. When diagnosing coverage for a horticultural crop, a distribution of 85 medium deposits/cm2 and 10-15% coverage is a reasonable standard for most applications.

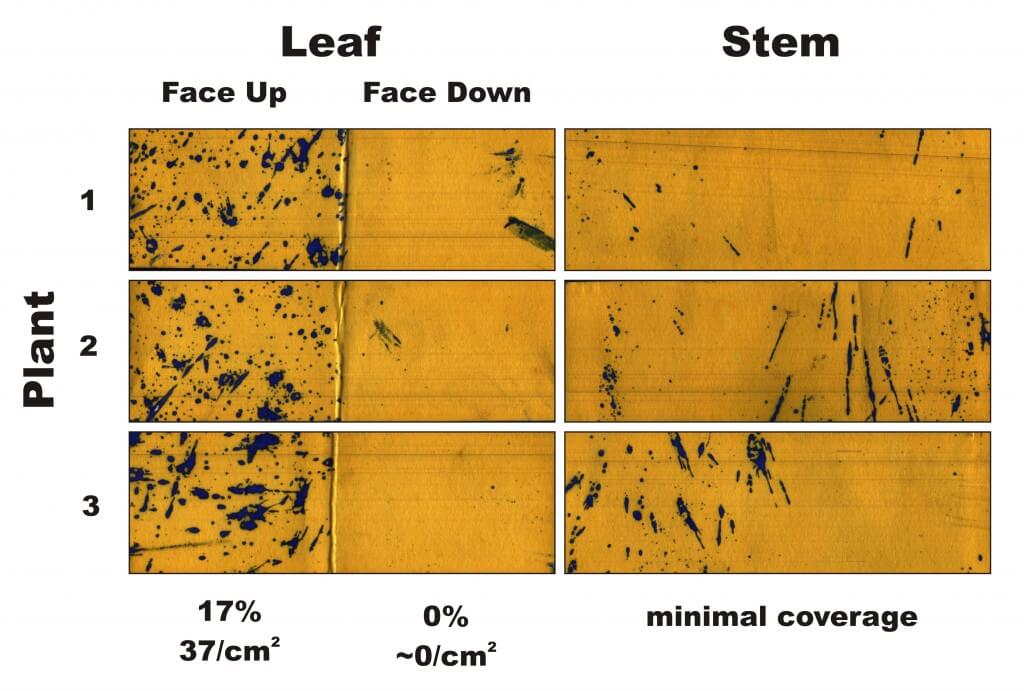

The first condition (the AITX tips) averaged 17% coverage on upper leaf surfaces (37 deposits/cm2). These were coarser droplets at relatively low volume, so it was no surprise that we didn’t achieve 85 deposit/cm2 target. When using such large droplets, it is more important to achieve an even distribution and the 10-15% surface coverage (we achieved 17%). There were no deposits on the underside of the leaves (See figure 1), but that was also expected as coarser droplets tend to follow a downward vector that is not conductive to under-leaf coverage.

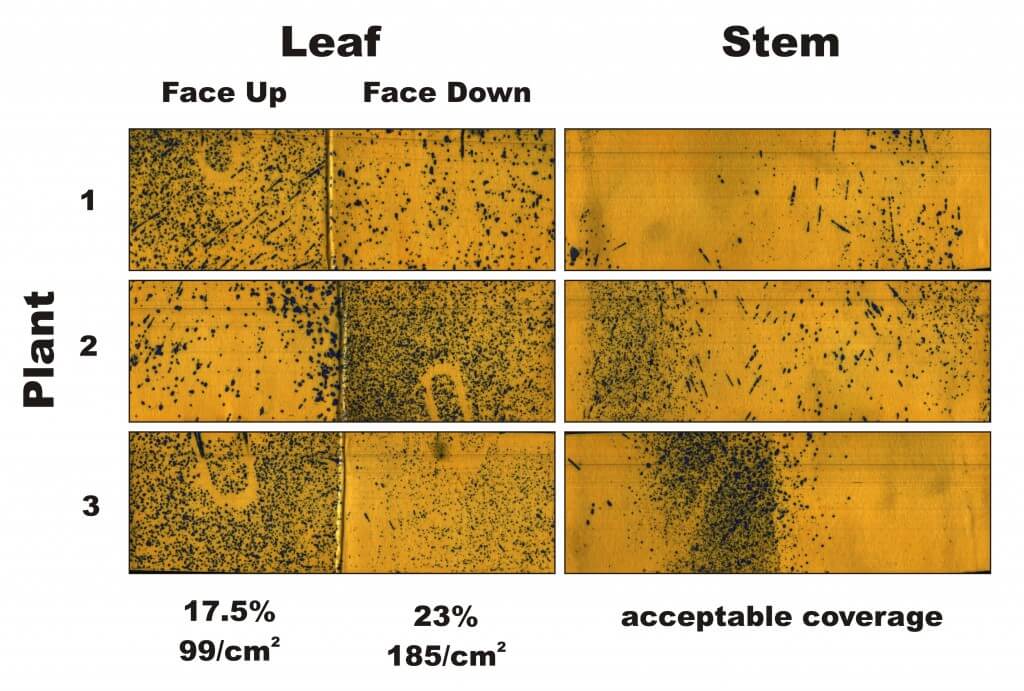

The second condition (the ConeJets) provided better coverage. The fine droplets produced covered an average 17.5% coverage with a distribution of 99 deposits/cm2 on upper surfaces, and 23% coverage with a distribution of 185 deposits/cm2 on lower surfaces. Panoramic stem coverage was improved as well (see figure 2). This is excellent coverage, but the finer droplets were highly prone to drift (see below). With no form of drift control, this set up is undesirable.

This led us to propose a more directed boom arrangement: We set up a hollow cone over the row (the grower’s original ConeJet) and a drop hose suspended in each alley with two TeeJet XR 8004 flat fans positioned on an angle (i.e. not vertical or horizontal to ground). This gave sufficient height to span the canopy with as little direct waste on the ground as possible. As the crop grows, the nozzles would need to be twisted into a more vertical alignment.

We did not use an air induction fan to avoid the Very Coarse spray quality and we used 80° instead of 110° to ensure the spray did not overshoot or undershoot the plant. Here are the details of the third set up:

3. TeeJet ConeJet TXVK-18’s on 100 cm (40″) centres at 7 kmh (4.5 mph) and 3.44 bar (80 psi). That’s 1.6 L/min (0.42 gpm) per nozzle. Also, two TeeJet XR 8004’s per drop on 100 cm (40″) centres at 7 kmh (4.5 mph) and 3.44 bar (80 psi). That’s ~4.5 L/min (1.2 gpm) per drop hose. Together, set of nozzle for a total rate of 523 L/ha (56 gpa).

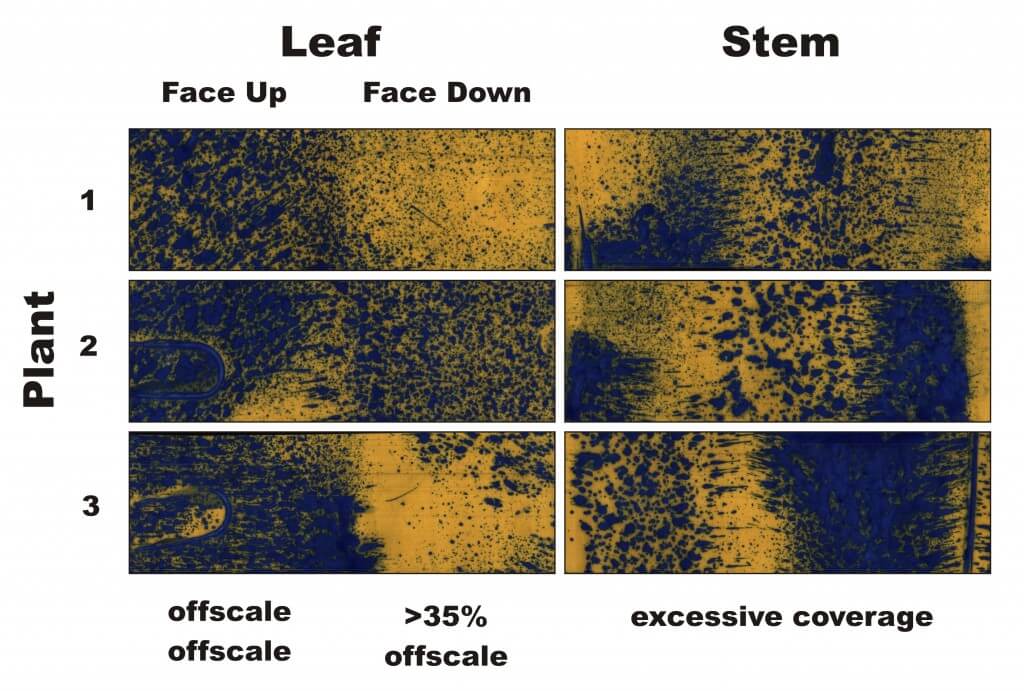

This set up raised the volume considerably and aimed spray directly at the sides of the plant. Coverage was excessive and in a few cases exceeded what the diagnostic software could reliably resolve (see figure 3). Since the plants were still small at this stage, it was decided we would let them “grow into the volume” and come back to check coverage once they were at full size.

When we returned in mid-August the plants had reached full maturity. In this final coverage trial, we added a second water-sensitive paper to each plant to span the height of the crop canopy, which had grown considerably.

Coverage was reduced compared to how we left things in July, but appeared to be sufficient on key surfaces (see figure 4). The papers showed upper leaf-surface coverage of 63%-to-offscale and deposit distribution of 137 deposits/cm2-to-offscale. Coverage on the lower leaf surfaces was greatly reduced to 4-4.5% and 36-90 deposits/cm2. Panoramic stem coverage was present, but minimal. Applying higher volumes would likely have improved matters.

When asked about the drop hoses, the grower reported “They are a bit of a nuisance because they take extra time to put on, and they get caught in the bush at the back of the field. But if they increase our coverage, then they’re worth the extra effort.”

Final thoughts

Adding drop hoses to a vegetable sprayer may be unconventional, but if fungicide coverage is a concern, and the drops will fit between rows, they might be worth a try. Carefully consider the volumes you use because they should reflect the size of the plant canopy you are trying to protect. Finally, water-sensitive paper provides excellent feedback to help you decide if your field volume, nozzle rates and nozzle positions are providing acceptable coverage.