In 2019 we evaluated the spray coverage from nine application methods on corn silks. The results showed that a directed application from drop hoses (aka drop pipes, drop legs) suspended in between the rows gave significantly higher deposits. The results led us to wonder if the superior coverage from a directed application translated to improved yield.

Around this time we started considering the Beluga Drop Hose developed by Agrotop (Germany) and distributed by Greenleaf Technologies (USA). Originally designed to apply neonicotinoids in canola, we found that the stiff-but-flexible hose did not tend to deflect or sway during an application. Further, their unique low-profile nozzle body had less potential to cause mechanical damage or otherwise snag in dense canopies. Unlike homemade drop pipes or other commercial solutions such as the Y-Drop with 360 Undercover, the Belugas were lightweight, simple to install/remove, and did not need a break-away section to prevent damage.

In 2021 we initiated a multi-year trial with the Beluga drop hose system in Port Rowan, Ontario. Our objective was to evaluate return-on-investment based on yield using two pesticide regimes. Treatments were established for conventional overhead technology, directed applications (i.e. the Beluga) and unsprayed checks.

Construction and Installation

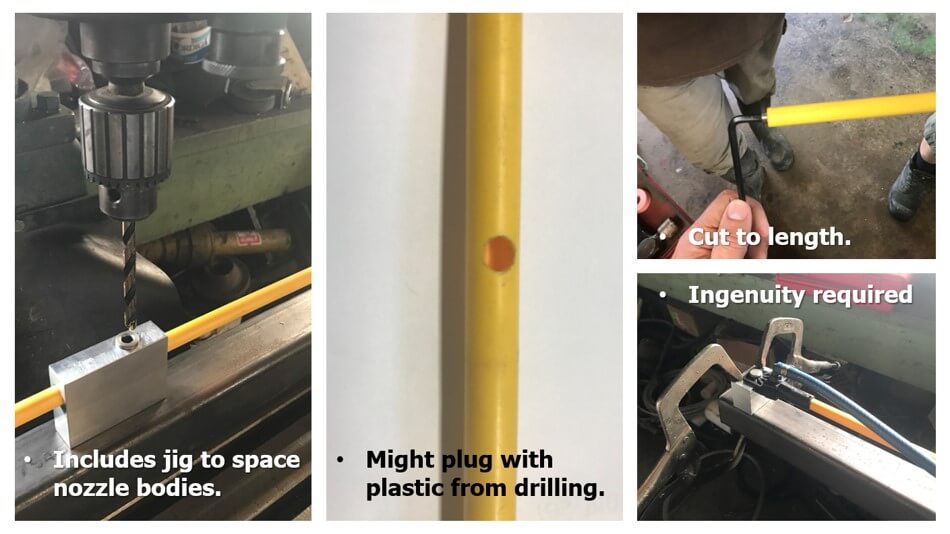

We ordered 150 cm (60″) drop hoses with two nozzle bodies each so we could customize them. The instructions were in German, but after running them through translation software we were confident in how to proceed (download the translated copy here). We started by determining the hose length.

Hose Length and Boom Spacing

We started by temporarily fixing the mounting plates to the boom using quick ties because we wanted to ensure they did not interfere with boom folding. The drop hose quickly and easily “keys” into the plate allowing it to swing freely and find plumb. The corn was planted on 76 cm (30″) spacing so we aligned the plates with the alleys to permit the drop hoses to move between the planted rows. Each hose is plumbed to the nearest nozzle body via a quarter-turn quick-connect coupler.

The drop hose had to clear the ground but still be long enough permit nozzle bodies to span the target region in the canopy. We later learned to cut the excess hose closer to the lowest nozzle body. This eliminated a source of pesticide collection (like a boom end) and prevented them touching the ground and “walking” as occasional contact would cause them them to flex and leap forward.

Target Zone and Nozzle Body Spacing

Before we could permanently install the nozzle bodies on the drop hoses, we had to decide what our target was. This required us to establish a primary coverage zone within the corn. Dr. David Hooker (University of Guelph) experimented with directed sprays (triazoles) and leaf disease control in the 2010’s. Dr. Hooker noted that leaf diseases were controlled above the ear to the flag leaf, and postulated it may be due to xylem mobility (i.e. acropetal movement) of the fungicides used at the time. This concept warrants further investigation with modern fungicides, especially with the need to control tarspot and reduce DON risk in SW Ontario.

Given that the nozzles would be about 38 cm (15″) from the stalk, we elected to use 110° flat fan nozzles on two nozzle bodies spaced 50 cm (20″) apart to increase the swath. Our objective was to protect against foliar disease, so the bottom nozzle was aimed approximately at the ear (for silk coverage) and the upper nozzle covered the higher foliage without being so high as to spray out of the canopy. Between gravity, the wake of the drop hose, and the initial angle of the spray, all surfaces received some degree of spray coverage no matter their orientation or depth. This was later confirmed using fluorescent dye.

It has been suggested that this target zone may not be ideal for all hybrids, and that an overhead component should be included. However, we felt this was the most efficient distribution of the spray given Dr. Hooker’s observations and the results from the 2019 spray coverage work referenced earlier.

Using the jig provided, we drilled holes for the two nozzle bodies. Then we blew-out the hoses to clear them of any plastic shavings that could plug nozzles. The hoses were cut to length and the end plug was installed with a hex key. Once we found a rhythm, the assembly went quickly and easily.

Plot Design, Sprayer Set-up and Chemistry

The study took place on 11.3 ha (28 acres) spanning two fields. The corn variety was Pioneer P0720AM, which has a Gibberella Ear Rot rating of 4. Four overhead treatments, four directed treatments and four unsprayed checks were arranged in a random block design for each of two fungicide regimes (n=8 for each treatment per year). Each treatment area was between 1.05 and 1.10 acres..

The sprayer was a self-propelled John Deere R4038 with a rear-mounted 36.5 meter (120′) boom. Treatments were eight corn rows wide, so the boom was nozzled to permit all three treatments in a single pass. Travel speed was between 8.85 – 11.25 km/h (5.5 – 7 mph) and the application volume was 225 L/ha (20 gpa).

Nozzle choice is indicated in the following table. Note that after the first year, we elected to use a smaller droplet size on the Belugas; This gave the advantage of higher deposit density with little or no risk of drift from inside the canopy.

| Year | Broadcast (Overhead) | Directed (Beluga) | Unsprayed Check |

| 1 | TeeJet AIC11005’s on 15″ centres | 4 Airmix 110015’s per drop on 30″ centres | Nozzles blocked |

| 2 | TeeJet AIC11005’s on 15″ centres | 4 Spray Max 110015’s per drop on 30″ centres | Nozzles blocked |

| 3 | TeeJet AIC11005’s on 15″ centres | 4 Spray Max 110015’s per drop on 30″ centres | Nozzles blocked |

Two tank mix regimes were applied each year, as indicated in the following table. Tank mix 2 changed based on pesticide availability and the farmer cooperator’s preference. The insecticide “Delegate” (50 g/ac) was also included in each tank mix. However, there was very little evidence of the target pest (Western Bean Cutworm), so the impact of Delegate will not be discussed.

| Tank Mix (Year) | Product | Rate (/ac ) |

| Tank Mix 1 (all) | Miravis Neo | 405 ml |

| Tank Mix 2 (2021) | Headline AMP + Caramba | 303 ml + 400 ml |

| Tank Mix 2 (2022) | Veltyma + Proline | 202 ml + 170 ml |

| Tank Mix 2 (2023) | Veltyma + Caramba | 202 ml + 400 ml |

There was no obvious difference between the fungicides used so we will not be discussing the relative efficacy of each tank mix in this article. Instead, the results are combined and only the application method and total cost of fungicides are compared in this study.

Qualitative Results

Leaves

In all three years, a qualitative comparison of randomly-selected ear leaves showed less evidence of disease in the fungicide treatments compared with the unsprayed check. There was also less evidence of disease in the Directed application treatments versus the Overhead broadcast application treatments.

Cob Size / Quality

In all three years, preliminary samples showed evidence of disease and tapered-ends in both fungicide treatments and the unsprayed checks, but trends indicated improved size and quality of the cobs from fungicide treatments. It was difficult to discern any difference between Overhead and Directed application at this stage.

Quantitative Results

Net Revenue

Each treatment yielded corn with different moisture levels, so we chose not to compare bushels per acre harvested. Instead, we calculated net revenue for each year based on the current market values in the Port Rowan area. We normalized the treatment yields by moisture level and calculated their relative drying costs. Then we accounted for the other inputs (see list below) using the following formula:

Net Revenue (CDN) = Seed Yield × Corn Sale Price – Drying Cost – Treatment Cost

| Item | 2021 ($) | 2022 ($) | 2023 ($) |

| Corn Sale Price (/bu) | 6.00 | 8.00 | 6.50 |

| Custom Spray Cost (/ac) | 12.00 | 12.00 | 15.00 |

| Drying Cost based on Moisture Levels (/bu) | 0.58-0.64 | 0.60-0.69 | 0.49-0.56 |

| Tank Mix 1 (/ac) | 16.66 | 18.24 | 18.50 |

| Tank Mix 2 (/ac) | 15.75 | 28.52 | 22.09 |

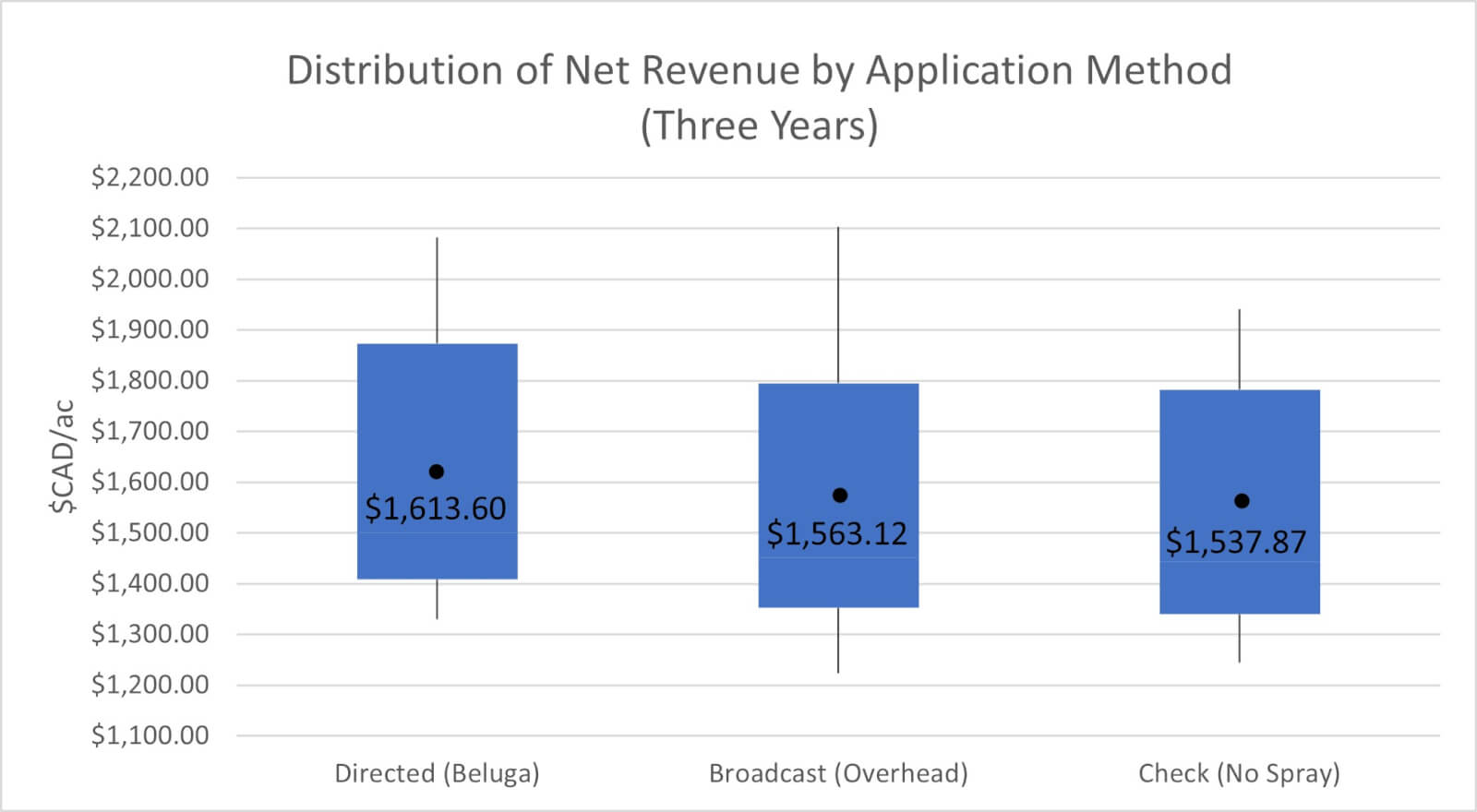

We plotted net revenue from each application method in a box and whisker plot (see below). T-tests did not indicate a statistically-significant difference between application methods and the unsprayed checks at a 95% confidence level. Nevertheless, trends remain consistent year over year.

| Year | Treatment | Yield (bu/ac) | Moisture (%) | Average ROI ($/ac) |

| 1 | Broadcast vs. Check | -2.26 | +0.58 | -0.49 |

| 1 | Directed vs. Check | +3.48 | +0.60 | +20.93 |

| 1 | Directed vs. Broadcast | +5.74 | +0.01 | +21.42 |

| 2 | Broadcast vs. Check | +9.79 | +0.22 | +52.48 |

| 2 | Directed vs. Check | +14.56 | -0.04 | +89.14 |

| 2 | Directed vs. Broadcast | +4.77 | -0.26 | +36.66 |

| 3 | Broadcast vs. Check | +8.4 | -0.2 | +23.7 |

| 3 | Directed vs. Check | +22.7 | +0.2 | +117.1 |

| 3 | Directed vs. Broadcast | +14.4 | +0.4 | +93.4 |

| All | Broadcast vs. Check | +5.3 | +0.2 | +25.24 |

| All | Directed vs. Check | +13.59 | +0.25 | +75.72 |

| All | Directed vs. Broadcast | +8.29 | +0.05 | +50.48 |

- Directed (Belugas) vs. Unsprayed check: Profit of $75.72/ac CAD

- Directed (Belugas) vs. Broadcast (Overhead): Profit of $50.48/ca CAD

- Broadcast (Overhead) vs. Unsprayed check: Profit of $25.24/ac CAD

Return on Investment

We can estimate the return on investment for this scenario. In 2021, 48 Beluga drop hoses ($9,600.00 CAD) with 192 nozzles ($1,920.00 CAD) cost $11,520.00 CAD. The cost of Beluga drop hoses increased to $12,000.00 CAD in 2023, increasing the cost to $13,920 CAD. Compare this to the cost of 72 nozzles ($720.00 CAD) in the Overhead broadcast application method. Based on the mean net revenues in this study, the Beluga drop hose method would pay for itself in 261.5 acres.

($13,920.00 – $720.00) ÷ $50.48/ac = 261.5 ac

The following video filmed by Real Agriculture discusses the return on investment based on 2021 and 2022 data.

Mycotoxin Assays

We submitted samples for lab analysis of mycotoxins for each treatment, annually. However there are many factors that influence ear mould pathogens, and we did not see any clear correlations between the fungicides or application method used and the level of Deoxynivalenol (DON aka vomitoxin) or zearalenone detected. We may publish these results in a separate article in the future.

The Drop Hose Experience

We felt it was important to describe the utility and user-experience. While this study focusses on the Port Rowan trials, several other operators have adopted the Beluga system and reported on their experience. We have included their observations as well.

- Installing and uninstalling the drops took roughly 90 seconds apiece, including moving the ladder.

- Deflection was minimal, even when they were dragged perpendicular to the rows through headlands.

- The mounting bracket permits the drop to be “keyed in” from either side, however this may have led to drop hoses occasionally detaching in shorter corn stands and on sharp turns. The weak point may be the plastic hose barb, which can be damaged if the drops detach from the mounting plates. Rather than the current slot positions of “9:30 and 2:30”, “11:00 and 1:00” may prevent detachment. Mounting plates are currently being redesigned to compensate.

- Initially, it was a little unnerving not being able to see the spray but the operator quickly got used to it (see video below).

- There was no issue folding the boom or driving between fields with the drops installed. They did note that the lugs on the front tires did contact the drops on tight turns, but adjustments were made.

- There were issues with other sprayer types (e.g. New Holland Guardian) when folding the booms. Drops did not hang plumb during transport. New linkages are being developed to account for differences in boom design.

- The drop hoses rinsed as easily as any nozzle. New hose-end plugs are being designed to facilitate rinsing.

- There were initial concerns that using 015’s nozzles to maintain the target 20 gpa might cause plugging issues, but none occurred.

- The drops were resilient. The operator bent the hoses by lowering the boom and then dragged them along the ground. They returned to plumb and appeared undamaged. One operator elected to use a NutraBoss Y-Drop mount to stiffen the top few inches of the Belugas (image below) but no other user found this necessary.

- Once removed, the drops stored compactly and easily on a utility shelf, repacked in their original box or hung on the shed wall.

Custom Operators

Some custom operators have begun to use the Beluga system and have reviewed it positively, but others question the fit. The latter feel this technology makes more sense for a home farm operation where the drops can be cut to a size that aligns the nozzles for a specific combination of boom height and corn variety. The concern is that a custom operator would have to adjust boom height (if not already maxed) or swap drop hoses to configurations that align correctly with the client’s crop. However, three years in, early adopters have collectively sprayed more than 20 different corn varieties with multiple sprayers and have had no issues reaching the target zone.

Additionally, our study has focused on 20 gpa where some custom operators would prefer 15 gpa. We have promising preliminary data based on a limited set of trials based on 16.5 gpa (data still being analyzed). Reducing volume necessitates a change in travel speed (may not be practical) or a reduction in operating pressure (may increase average droplet size). It would be inadvisable to drop for 015’s to 01’s (think plugs and misty spray).

Both limitations translate to additional cost (currently about $2.00 per acre) to a client. The value proposition becomes the added cost for an efficacious application versus the potential losses should conventional application methods fail to control devastating diseases such as Tar Spot and Northern Corn Leaf Blight.

Conclusion

We have seen a consistent annual increase in mean net revenue from corn sprayed using directed application versus a conventional overhead broadcast. The low price point, ease of use, and high rate of return make this an attractive proposition in corn production.

Thanks to Petker Farm Ltd. and other early adopters for participating in the study. Thanks to Corteva and Syngenta for contributing the pesticides used.