In 2013 we ran a sprayer coverage demonstration in a ginseng garden in Norfolk County, Ontario. The goal was to encourage growers to reconsider their spray operation with an eye to coverage. We performed a down-and-dirty comparison between simple disc-core nozzles and the considerably more expensive Arag Microjets. Opinions were mixed, but we were confident the humble disc-core could do the job.

One grower took the day to heart.

Having experienced Alternaria infection (likely due to frost damage) in the outer rows, he decided to buy a few packages of water sensitive paper and put his spray boom to the test. Multiple ground speeds, nozzle choices, pressures, spray volumes and even nozzle orientations were tested. This led him to what we will call “ideal coverage” from what may be the perfect ginseng boom.

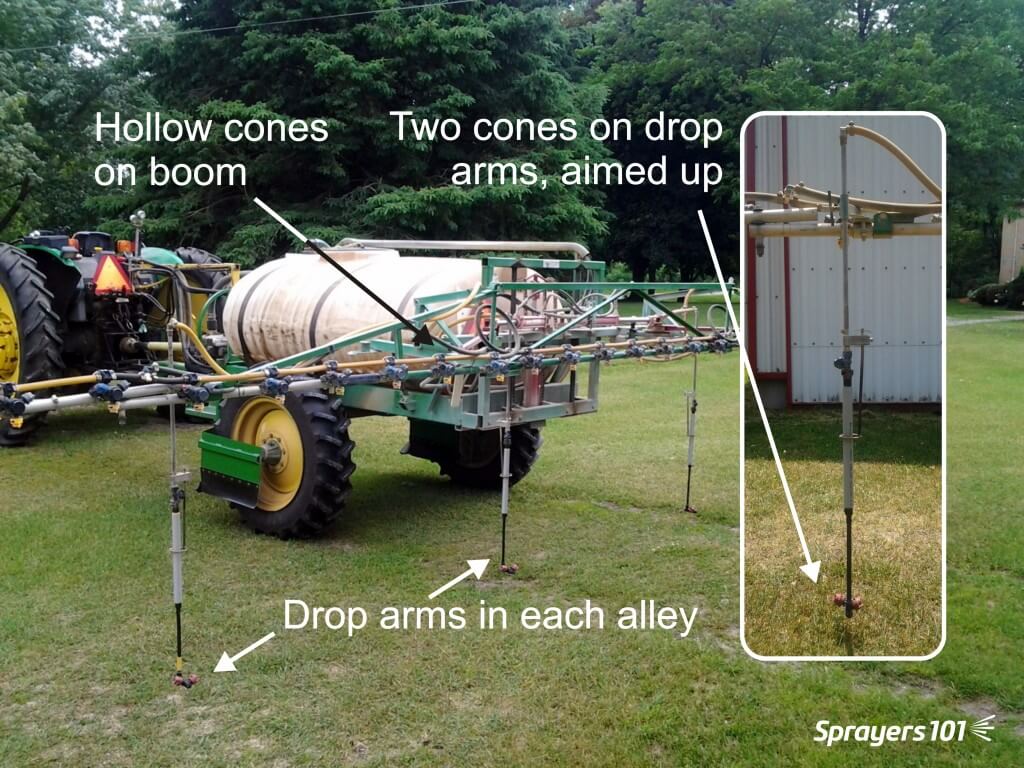

On June 15th, the temperature was about 22 °C, winds were light and humidity was about 40%. The nozzle arrangement was 24 D4-45’s (hollow cones) on the horizontal booms, spaced every 50 cm (20 inches). The grower built four drop arms, hung over each alley (not just behind the wheels) with twin bodies that each held two D5-35’s (full cones), for a total of eight dropped nozzles.

His output was ~1,000 L/ha (115 US gallons per acre) and he sprayed at ~14 bars (200 psi) and he was travelling at ~7.2 kilometers per hour (4.5 miles per hour).

Compared to traditional methods, that’s low pressure and low volume for ginseng. The ground speed was reasonable given the art of negotiating a sprayer under a shade structure. Collectively, this is a savings in fuel, water and pesticide.

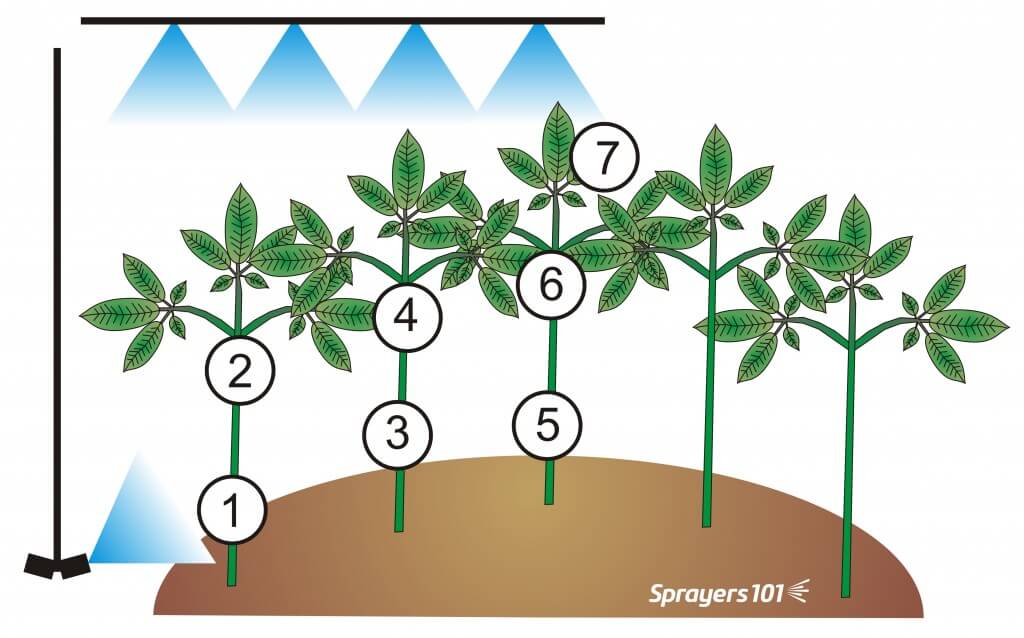

Water sensitive papers were placed in seven positions (see image below) in a three-year old garden. In each position, the papers were folded so the paper wrapped around the stems and could show coverage facing each alley. They were placed on the stems just above the ground and just below the canopy on three plants. The seventh card was folded over the uppermost leaf, to show coverage on the adaxial (top), and abaxial (underside) of the leaf.

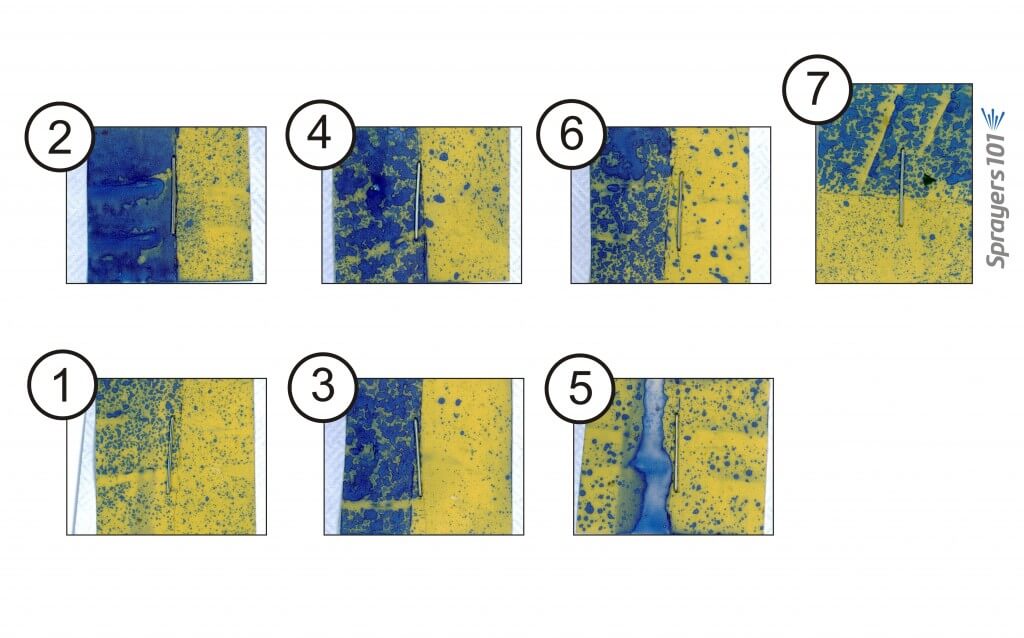

The coverage was excellent. A completely blue card represents a drench, which isn’t necessary but can be difficult to avoid when trying to spray all surfaces in a dense canopy. The rest of the papers show a high droplet density which tends to lead to an effective application. Ideally, hope to see 10-15% coverage and >85 droplets per cm2. This is a difficult or even impossible prospect for abaxial coverage, but we achieved it (note the lower half of card 7).

The trick, you ask? The full cones on the drop arms are aimed so the bottom of the cone is parallel with the ground (essentially, aimed up about 30°). That creates a cloud of spray moving under the canopy, improving the odds of contact on all surfaces. It is important to not spray the cone into the ground or the raised mound, and to spray in from both sides.

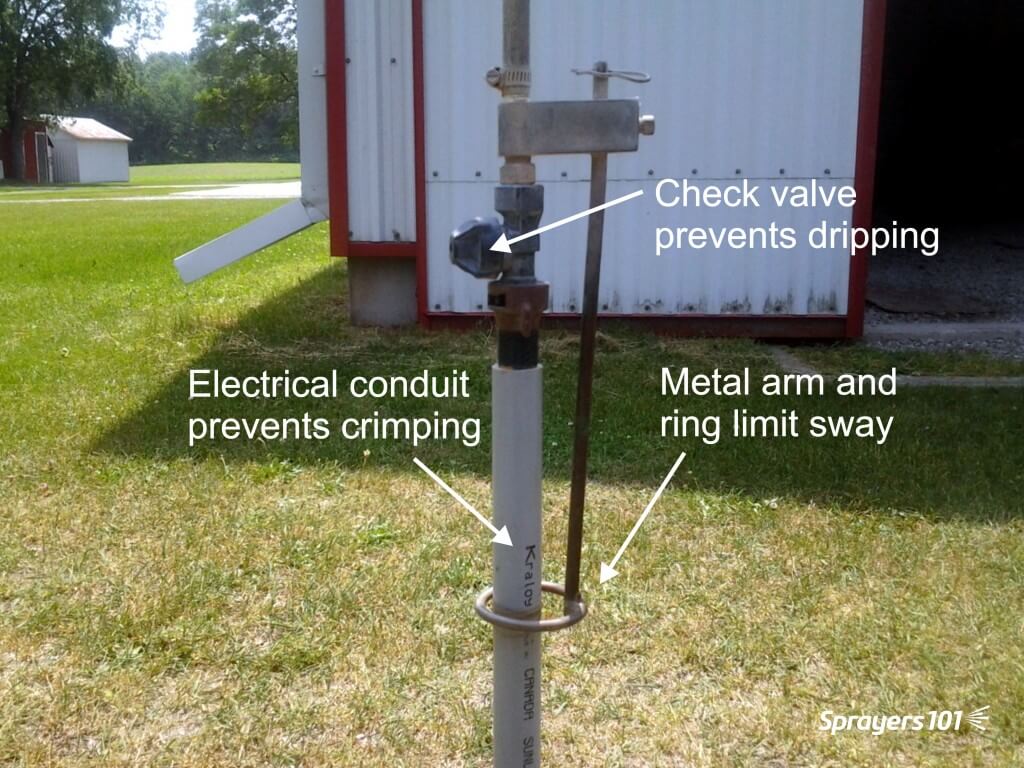

The drops themselves have been modified so they are flexible enough to move through an overgrown 3rd or 4th year garden (yes, there will be some leaf damage), but are also stiff enough not to sway. This was accomplished by sliding a sheath of electrical conduit over the drop arm and using a metal stabilizing arm that terminates in a ring around the conduit.

With the right timing and product choice this method of spraying will be hard to beat. And it’s cheap! It’s going to save fuel and wear because of lower pressures, and save spray mix because he can go a lot farther on a tank spraying only 1,000 L/ha.

For more information, check out the OMAFRA spraying factsheet for ginseng.

Special thanks and congratulations to Richard Klosler of Micheal Klosler Farms Ltd. for his great boom design!