In almost all agronomic practices, timing is key. There are certain, and often small, windows of opportunity for getting a task done without losing yield potential or product quality. Weed specialists talk about early weed removal, pathologists talk about symptom monitoring, and entomologists remind us of economic thresholds. Acting at the right time is fundamental.

Sometimes I’m asked about comparing two different methods of spray application. I usually dodge these questions by advising to choose the one that gets the job done on time. “An average application at the right time is much better than an excellent application at the wrong time” is how I put it. Sure, I’m dodging, but I really believe that. It’s mostly in the timing.

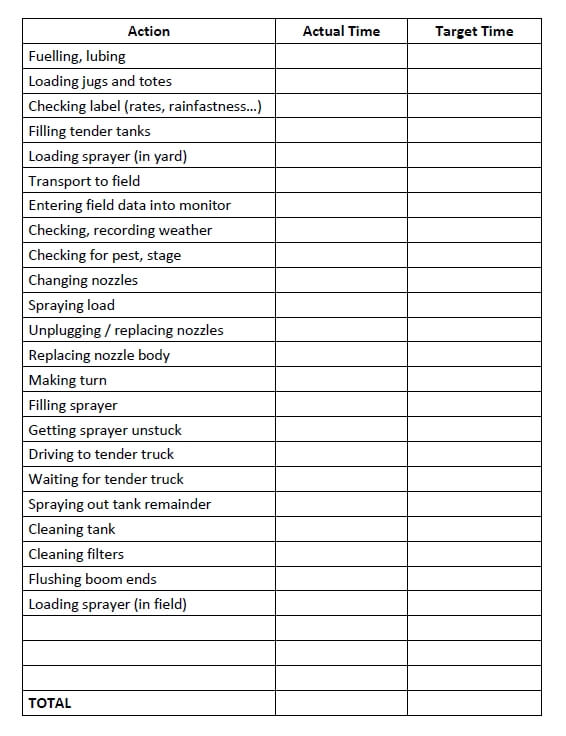

Everything we do carries with it some time inefficiencies. Some are rooted in technology, others in habits. It’s the habits that are easier and cheaper to address. That’s why, when evaluating how to improve a spraying operation, I advise to start with a stopwatch and notepad, not a sprayer brochure.

Remember, if you want to improve a system, you first need to understand it. And to understand it, you need to measure it.

So, do a time accounting. You need to know how your time is used on a spray day. Note the time spent preparing for the job (loading supplies, double checking label instructions, transporting, etc.). The big users of time are sprayer transporting, filling and cleaning, but there are very many small time users and those can add up. This time is doubly important because these tasks occur during the spray day, when the weather is good and you should be maximizing spray time.

Even within any one operation, time can be subdivided. How much time is spent on a turn? Since a 120’ sprayer will make about 22 of these per half mile, that can add up. Even a spray monitor can play a productivity role if it quickly and consistently locks onto its swath. Needing to stop and back up while it searches for a signal can be costly.

On our farm, we sometimes used custom operators to get the cereals off. I recall how aggravating it was to watch the 8820 inch ahead of my N6. Surely it must be throwing a lot over, I thought (it was). But I usually caught it at the truck, where my unloading speed was over 1 minute faster. Redemption, briefly.

That same principle applies to these small efficiencies. A well-designed tender truck can speed loading and more than make up for lower spray productivity of a smaller sprayer. A lighter sprayer load and flotation tires can save a ton of time if it means the difference between getting stuck or cruising through that spot. A set of extra-coarse nozzles that can be rotated into place in just two minutes can help finish a field if the weather changes, or allow a margin to be sprayed, saving a return trip.

A custom operator shared some very useful tips with me a few years back. He optimized the small things, such as re-locating the switch to deflate his suspension airbags after driving onto the trailer, to the platform beside the cab. He’d deflate while descending the steps, and by the time the tie-down straps were thrown across, the unit was ready to be cinched down. No waiting. He also opted for a slightly wider aftermarket boom so he had an even number of spray passes per quarter, saving another 2 minutes or so per field.

The same operator made me aware of the importance of knowing exactly how much spray is in the tank at any one time. The majority of spray monitors are simply not accurate enough. A factory sprayer can count down from a full tank using its flow meter, but that requires two things to be accurate, the filled amount (entered by the operator, usually from a sight gauge) and the flow meter itself. Point is, when we fill the last load of a field, we don’t want too much left over, but we’d still rather not run out. By using the AccuVolume from Simon Innovations, he was able to fill accurately and he was also able to exactly monitor his liquid usage. If he had two passes left, and knew he needed exactly 150 gallons (also considering when his pump drew air), he could monitor that and make small adjustments to the application rate, if necessary, to get there. It’s a big deal because contending with a larger remainder is wasteful and takes time to deal with. The AccuVolume also helps make multiple small volume batch cleaning more accurate, and therefore easier.

A small addition to the tender truck such as an electric hose reel or a swing arm that carries, say 20’ of hose, helps deal with the weight of a full 3” line. Or an air-line at the pump end can be used to blow the remaining water into the tank. Time, and mess, are saved. Still pumping product? Induction using a venturi is much faster.

Preventing problems is probably a better use of time than dealing with them. Take tank mixes, for example. With more products in the tank, and adjuvants such as conditioners, fertilizers, or low-drift products making their way in, anticipating mixing problems may require a jar test. Get the tools, and learn how to do them. It’s important to use the actual tended water in these tests, at the temperature it will be, because that, and water quality such as hardness and bicarbonates, can affect mixing. And don’t over-agitate, as that can create its own problems, especially as the tank runs down.

Consider a hot tank. If extra labour is available, it removes a lot of time pressure for mixing dry, or multiple products. At filling time, simply pump it over and go.

Consider improvements in the plumbing to save time. The new Hypro Express End Cap features a ball valve for flushing (existing Express End Caps can be retrofitted), and this valve can soon be fitted with the ProStop E (electric) valve. Flushing can then be done from the cab, saving time and mess. It’s a small change, but it brings joy.

The importance of time on a spray day can also be viewed economically. Let’s say a large area needs to be sprayed today, and the weather forecast calls for rain overnight. The rain will stop spraying for 5 days. What is the yield potential lost in those five days if weed or disease pressure is high? If 100 acres don’t get treated, what is the lost revenue? (for example, if 3 bpa is lost, at $6/b, that’s $18/acre or $1,800.) That’s what that hour is worth. Tell your boss.

Getting more done means getting more done on time. Evaluate your habits and technologies on that basis.