In June, 2016, someone tweeted a clever tip for sprayer operators. It got the usual round of likes and retweets, but it also inspired an idea. We decided to have a two week-long competition for the best North American tip under the hashtag #SprayerTopTips. The winner would receive a WeatherFlow windmeter. Shortly thereafter, Graham Smith (@retrofitparts) of RetroFit Parts generously volunteered a weather meter for the best UK submission.

After two weeks, we received 43 Sprayer Top Tips. Some of the submissions were best practices, some were equipment tweaks and some were downright funny. Thanks to everyone that shared their ideas, practices and sense of humour. Since Twitter limits a tweet to 140 characters, we took the liberty of interpreting a few of the tweets to ensure everyone understands the content.

Let’s be clear – we’re not endorsing any of the brands or practices here. There are some great ideas, but give it some thought if you’re thinking of adopting any of them. And so, in no particular order, here are the submissions for the 2016 #SprayerTopTips competition:

@a4nick – Any smartphone with apps weather, windspeed, calculator, camera, set up guides and Twitter <to access the> global knowledge of operators.

@Camcar_Ent – Put the dirt bike on the trailer to allow it to be moved where the sprayer will need a fill.

@Paulvdb2016 – Finally found the water cooler in the John Deere R series cab!

@Paulvdb2016 – Everybody breaks a few nozzle bodies each year! Save the turret part to organize your extra nozzles (WIND METER WINNER)

@LeightonBlashko – If your water/handler pump runs out of gas while spiking jugs, backflow will likely contaminate water tank. Keep fueled up!

@fortkampnathan – Add <an> electric valve to <the> mix system to keep solution agitated when spraying, and shut off when tank is near empty. Total cleanout.

@fortkampnathan – Valves on boom <section> ends to flush residue and prevent buildup in caps. Split <the> inductor and fill line to add <conditioner> with <the water>.

@twistedironfarm – Flush booms with water at night when shutting down to prevent residue buildup. Even if using same product the next day.

@landon707 – Don’t forget to feel the hubs to make sure you don’t have <one> hot one (HONOURABLE MENTION)

This got a reply from @1TonyHarding – One of these <see temperature gun image> is even better. Only ~10°C between a good and bad wheel motor on a Nitro <sprayer>.

@apple_grain – Talk to landlords before spraying. Some don’t understand what you are doing and why. A short chat can relieve a lot of anxiety.

@rmmathesonfarms – Stay out of the muck, it really is a buzzkill on productivity!

@T77HAM – Always organize a family day out when you want to go spraying to guarantee perfect spraying conditions.

@T77HAM – Make sure everything it greased well… putting it on its side <is> easier than scrambling underneath.

@GlenHanks – Air reel mounted on water trailer. #no blowback

@cfsdennis – Check <that> all wheels are on! <Editor’s note – This wasn’t just a photo lifted from the internet – this was his experience!>

@FreyTodd – It never hurts to double check that the field you are spraying is, in fact, all <RoundUp Ready> <More info here>

@EnnsFarmsRuss – Small blow gun tied into sprayer air system makes cleaning nozzles a breeze (WIND METER WINNER)

@EnnsFarmsRuss – A tackle box is great for keeping spare nozzles and parts and tools organized.

This got a reply from @thecropdoctor – Neater than my plastic ice cream tubs!

@thecropdoctor – Record headland sizes as well as landwork areas so if <you are> patch spraying, data is available.

@konopelskifarms – I spray #ReglonIon @ 20USgal/ac 6MPH 50PSI in evenings – awesome results!

@konopelskifarms – I spray Liberty at 20 US gal/ac. Great results including less bronzing. Lots of fills, but oh well.

This got two replies from @skellerfarms – We upped our water volume for Liberty from 10 to 13gpa, have fewer escapes now. More water is always the answer. <and> More water (10-13gpa) and slower speeds (<13mph) means better coverage and less drift.

@skellerfarms – Getting “too windy” but need to spray? Up <the> water volume by 3-5gpa and slow to a speed near your minimum effective pressure.

@landon707 – Eye/hand wash stations on sprayer and tender. We have a garden hose on tender for cleaning filters. <More info here>

@LegueeFarms – Pattison Totalizer – loads our R4045 in 7-8 min without hot loading.

@ONspraysafety – If you can see the maple leaf in the <Canadian> flag, it is too windy to spray!

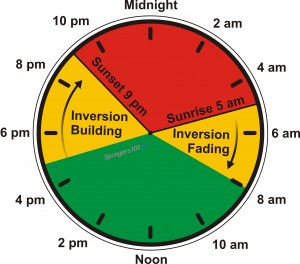

@ONspraysafety – If you hear sounds from far away on a calm morning, beware of a temperature inversion. <More info here>.

@WheatlanderJay – Use a 1,000 L tote with <the> top cut off for used jugs. We recycle all boxes so they never leave the shed.

@WheatlanderJay – The four R’s of spraying stewardship: Right Product, Right Rate, Right Staging, Right Application. #dontsprayandpray

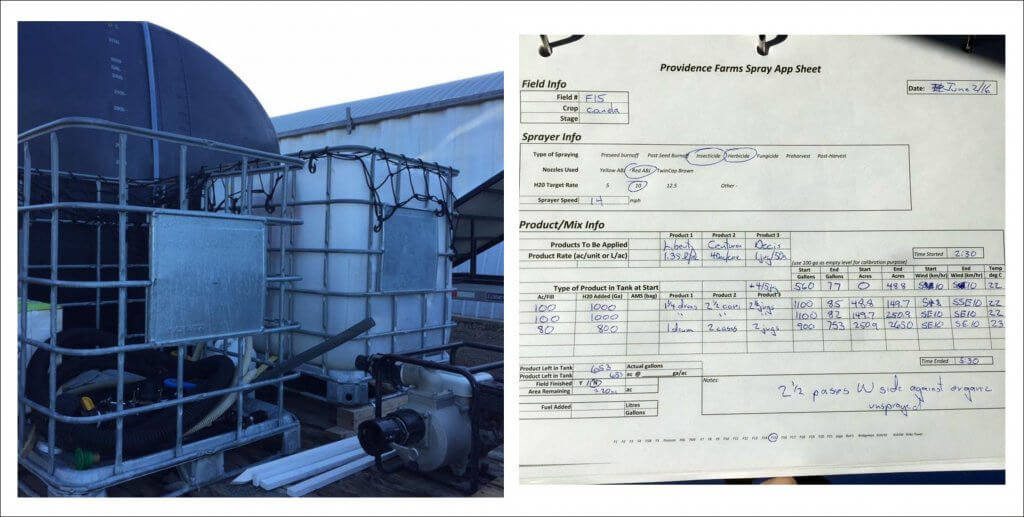

@RonKrahn – 1,000L tote cages <with> nets for <storage> boxes <left image>. Use a spray record sheet to keep track of fills and <environment> <right image>.

@redwoodacres – Plumb line directly into tank for pumping in bulk chemicals. <This> keeps big hoses chemical free.

@redwoodacres – Install fresh water connection for eductor/handler rinse water <with anti-backflow>. Cleaner jugs = less exposure.

@KeatingSeed -Keep a good custom operator on speed dial.

@GavinHowley – <Install a> float valve in tender tank, hook up hose, go home for <image of a few frosty beers>.

@DarylTuck – When spraying at 15 MPH and spray drift starts to pass the sprayer, it’s nap time!

@ehrinf – Reload, reload, reload? Cut that time to a minute and concentrate on spraying. <More info here>.

@BlackwellBrad – Re-purpose your old Davis weather station. Know wind speed and direction.

@a4nick – Mobile phone weather apps – very handy.

Thanks to everyone that shared. Maybe we’ll do it again in 2017!