What’s the most underused active ingredient when creating a proper tank mixture in a sprayer?

Patience.

Spray season is never long enough. The days which are most conducive to spraying are hard to come by. Therefore, the ingredient we need the most when spraying as well as tankmixing is patience. Without it, we are setting ourselves up for failure.

Successful bakers will tell you that patience mattered when perfecting their most decadent creations. By taking their time, adding ingredients slowly and mixing them carefully, those professionals create stunning masterpieces.

We can achieve a masterpiece as well, if we remember to slow down and apply the same principles.

1. Take your time

- Take 7-10 minutes between product additions to a spray mixture (especially dry formulations). Have a mini-vacation after each addition! This time allows each product to dissolve into solution and you can complete your spray records!

- Extra time allows pesticides to be fully integrated into the spray solution before another product is added, which could impede either formulation from mixing successfully.

- Each ingredient must be uniformly mixed before adding the next component. E.g. A soluble powder must be completely dissolved before adding the next item.

2. Add ingredients slowly

- Add products, one at a time, in the mix cone or inductor. If you’re adding product directly via shuttles and dedicated lines, the same principle applies.

- Rinse mix cone or inductor and lines with clean water between product additions.

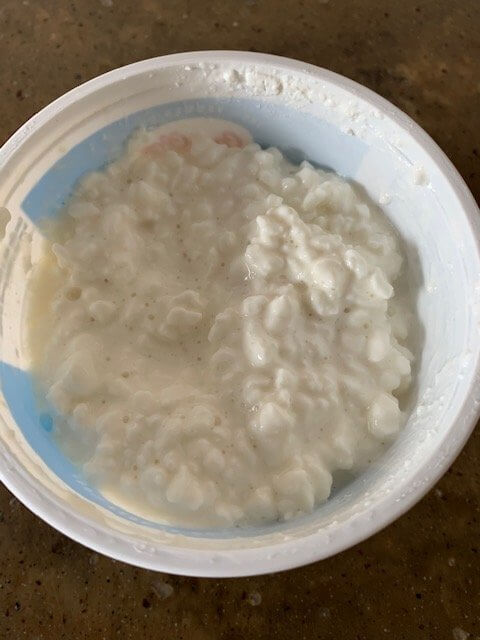

- Never “stack” ingredients on top of each other in the mix cone or inductor. Much like oil and water don’t mix, chem-on-chem doesn’t mix either. Active ingredients need water in order transition into solution. It’s vital to not pile products into a mix cone or inductor where they can form cottage cheese instead of a liquid solution.

- In my neighborhood, 3″ fill lines are not uncommon. They are a source of time savings when filling but they also bring additional cautions. Be aware of the problems over agitation can bring to what might have been a successful tankmix.

3. Mix carefully

- Start with sprayer tank 1/3-1/2 full to allow enough water to create a great solution.

- Pre-slurry dry flowables in warm water whenever possible. Yes, it takes additional time and effort but it can prevent having to wash out individual nozzles and strainers later. Or worse, there’s the possibility that the tiny grains of an active ingredient that did not blend into the solution may cause injury to a off target crop.

- Mix ingredients in the right order! Typically, crop protection products have a mixing order specified on their labels. Read the label and be familiar with the correct formulations you are currently spraying.

- Adjuvants are added in the same sequence as pesticides, e.g., ammonium sulfate is a soluble powder, oil adjuvants are emulsifiable concentrates; and most surfactants are solutions.

- Within each group, it is common practice to add the pesticide before the adjuvant, e.g., a soluble-powder pesticide before ammonium sulfate.

Final thoughts

Taking the extra 30 minutes now to load the sprayer carefully will save you the potential of 4 hours of having to clean out an entire tank later!