We’ve had dire warnings about possible pesticide shortages and price hikes for 2022. Price hikes are one thing. But if the products we need simply won’t be available, we have a tougher challenge. It’s time to plan pesticide conservation.

But first, what’s behind the product shortage?

Emily Unglesby of dtnpf.com provided an excellent overview of the issue here and here. She said the reasons for the shortage are many-fold and came together in a perfect storm. Starting about 2017 or so, pesticide manufacturers tried to reduce the overall inventory of products to improve logistical efficiencies. That effort was rewarded in 2019 when a wet spring in the US dramatically reduced seeded area to a low of 165 M acres. The resulting lower demand again provided incentives to reduce inventories. At the same time, US trade sanctions against China in the form of tariffs impacted production and shipment of many active ingredients to US markets. When Covid-19 happened, it affected both production and shipping of many goods, including pesticides. Container shipment costs increased sharply, and the ability to move them to and from ports was hampered. This then coincided with record seeded area in the US of 180 M acres in 2021, creating higher than usual demand. By that time, very little buffer remained in the system. The growth of Enlist E3 and Xtend Flex has placed additional pressure on glufosinate.

Then two further events occurred. Hurricane Ida forced a shutdown of Bayer’s Louisiana glyphosate plant. And China, in late 2021, legislated a temporary 90% reduction of yellow phosphorus production in Yunnan Province in anticipation of the 2022 Olympic Winter Games. With phosphorus as a fundamental ingredient in glyphosate, glufosinate, and some fertilizers, this loss of production places significant strain on many products. The usual habit of returning unused pesticides to the retailer also became less common amidst shortage news, adding difficulty to planning inventories and demand.

Shortages of popular herbicides like glyphosate, glufosinate, and clethodim will put demand on alternatives. Spreading out risk by implementing pre-emergent products where possible will pay dividends. But the ability to ramp up production of minor products is just as dependent on the supply chain, and these alternatives may therefore not offer reprieve if ordering is left to the bitter end. Planning ahead and staying in touch with retailers about your plans and your own inventory will assist the entire system in managing production and redistributing existing stocks.

Safe to say products will be more expensive, and possibly impossible to obtain. Here are some things to consider to minimize the impact.

1.Grow crops that require less pesticides. Crops which have good genetic resistance to insects and disease will be more likely to cope without a protective spray. Some crops are inherently competitive early on and give less time and space for weeds to become established. Remember that the relative time of emergence is important for crop yield loss from weeds. If crops emerge before weeds, they have the upper hand and will maintain higher yield potential. Crops that can be seeded early will prevent weeds from occupying that niche.

2. The most powerful herbicide is a competitive crop. Use agronomic tools that favour good seedling establishment. The usual advice of seeding into a warm, firm, moist seedbed, should we be fortunate enough for the weather to cooperate, applies here. There is value in higher seeding rates to help outcompete weeds. Use fertilizer placement that favours crops, not weeds, such as side banding.

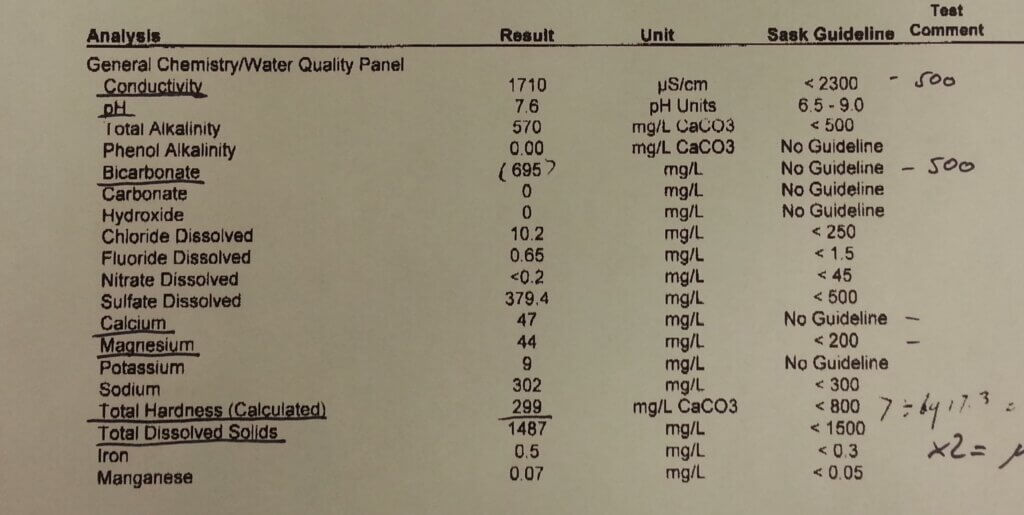

3. Sample the spray water source and have it professionally tested. After a record drought in western North America, aquifers are low and surface waters have receded. Water quality will probably not be the same it has historically been. Use water conditioners to reduce effect of hard cations and bicarbonates. Ammonium Sulphate (21-0-0-24) at 1% w/v is a general treatment, harder water may require up to 3%.

4. Do not use untested mixes of pesticides with specialty foliar fertilizers. These may impact herbicide performance, or worse, result in an incompatible mix.

5. Use the lowest label rate of product that is relevant for the pest you’re trying to control. Many products have a range of rates depending on the weed species and stage. Scout your fields and take advantage of the lower rate option if you can.

6. Spray herbicides early. It’s been shown that crop plants can sense the presence of weeds before they compete for resources, causing a physiological adjustment that results in irreversible yield loss. The shorter the time that weeds and crops co-exist, the better. Also, smaller weeds are easier to control. Weeds that escape this early application will need to compete with an established crop and won’t thrive or impact yield as much.

7. It’s not advisable to reduce product rates from the one recommended on the label. Although label rates contain a margin for poor conditions, the risk of selecting for polygenic resistance exists. Polygenic resistance occurs when some weeds happen to be slightly more tolerant to the herbicide than the rest of their cohort. These weeds may survive a lower rate, and go on to produce seeds. If these outcross with other survivors, their more tolerant offspring will increase in relative abundance. With further such selections in subsequent generations, weeds become even more tolerant and eventually dominate.

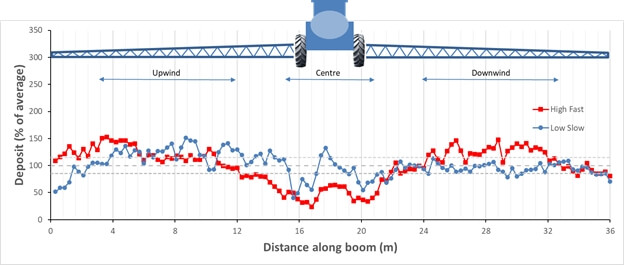

8. Apply the spray as uniformly as possible. Make sure the spray nozzles are within a 5% flow rate tolerance along the entire boom. If the set is older, consider a wholesale replacement. But the biggest enemy of uniform deposition seems to be turbulence created by wind and driving speed around the tractor unit. Slower wind and travel speeds help somewhat. Variable deposition means that some regions receive up to 50% more than intended, and others receive 50% less. This means weeds in the lower deposit regions may survive the application. The more variable the application, the higher the rate that is needed for acceptable control.

9. Use finer sprays whenever the tank mix contains a contact mode of action product (e.g., Group 1, 6, 10, 14, 15, 22, 27) or targets grassy weeds. Both situations require smaller droplets for best performance. The use of finer sprays may mean fewer hours in the day when drift is acceptable, and as a result, investment in efficient tendering and cleaning as well as overall time management pays dividends.

10. Make efficient use of the product in the tank, preventing waste. The amount of product being discarded can range to over 10% of the total needed to treat a field, but this can be reduced to 3% with the proper steps. The following are areas where improvement is possible:

(a) Prime the boom efficiently using sectional shutoffs or better yet, a recirculating boom. These can be primed without any spray leaving the nozzle or boom ends.

(b) Measure the spray mix of the last tank accurately, minimizing leftover. Consider the AccuVolume system that weighs the tank contents to the closest gallon. Tanks can be filled with the exact amount, and rates can be adjusted as the leftover becomes apparent on the last passes.

(c) Invest in individual nozzle shutoffs to improve sectional control resolution. These are part of any Pulse Width Modulation system but can also be obtained as air-actuated valves that are very affordable. Such capability is necessary for recirculating booms.

14. Consider an optical spot spray system such as the WEEDit Quadro, the Trimble WeedSeeker, or the John Deere See & Spray Select, available for 2022. These systems are “Green on Brown”, meaning they selectively spray just weeds in a burnoff or chem-fallow. This can save about 70% of the spray depending on weed density. More such systems are on the way, some even offering “Green on Green” that selectively identifies weeds among a crop. The return on investment of these systems is directly related to the pesticide cost, meaning in a year with high pesticide prices they pay off faster. If shortages of product become a reality, a spot sprayer may be the only way that some fields get treated at all.

Pesticide shortages will not be fun. Unfortunately, their appearance coincides with higher fertilizer prices, meaning crop establishment will need to overcome that factor as well. But there are tools to minimize the impact if we’re willing to implement them. Just as necessity is the mother of invention, scarcity is the father of conservation.