Spot spraying promises to dramatically cut herbicide use. Data from Green-on-Brown (GoB) sprays suggest at least 50% and possibly 90% savings are possible, depending on weed density and the system employed. These savings are significant. But system performance depends on the nozzle selection even more than for broadcast sprays. What are the issues?

Pattern Width

Spot sprays represent a unique mix of single nozzle banding and multiple nozzle broadcasting on the same boom at different times and locations, depending on what the weedy spots require. Both need to be optimized to get the best performance and savings out of such a system.

Even (Banding) Nozzles

Let’s say the spot spray boom has a spacing of 10” (25 cm) and is carried by wheels to ensure consistent height. An operator would want the spray pattern to have a very similar width as the nozzle spacing. A 30 degree even fan angle would create a band of about 10” wide at a boom height of 19” (48 cm, download a worksheet that solves this for any fan angle and boom height here). Assuming a travel speed of 12 mph (20 km/h) and a pressure of 40 psi (2.75 bar), an 03 sized nozzle would apply 14.9 US gpa (139 L/ha) in these 10” wide bands.

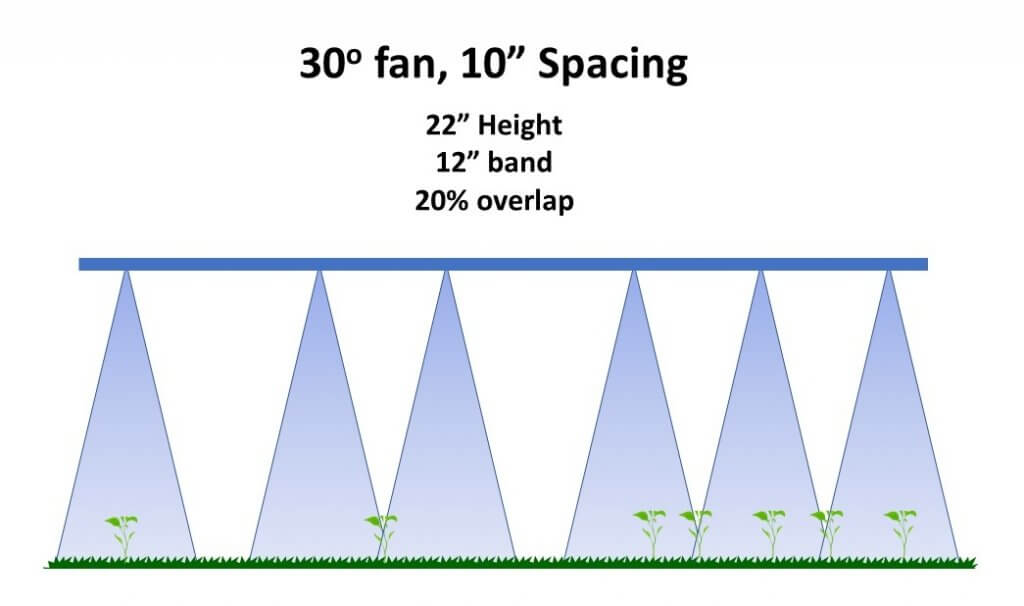

But most applicators would be uncomfortable with zero overlap, and would prefer to raise the boom to allow, say, 20% overlap. This would ensure targetting of taller weeds that appear exactly between two sprays, for example. At 22” (56 cm) boom height, the pattern would be about 12” (30 cm) wide and affording 1” overlap on either edge.

Because the application is diluted by the extra pattern width, the applied volume is now 12.4 US gpa (116 L/ha), about 20% less than before. This change is easily accommodated by mixing the product more concentrated in the tank. The downside is that the overlap in banded sprays receives twice the dose, and this is less than ideal.

Tapered (Overlapping) Nozzles

A possible solution is to employ tapered flat fans that are the standard type on broadcast booms. These produce more of their volume in the centre, diminishing at the edges, to allow for overlapped patterns and thus functioning better when more than one nozzle is activated. In addition, the extra coverage from a wider pattern is not as wasteful as it is from an even pattern type since it comprises less volume. A single nozzle spray, however, would have a higher dose in the centre than at the edges, since a single pattern has a bell-shaped volume distribution. (note: a single nozzle moving through air loses some of its volume from the centre and places it at the edges, due to aerodynamics of the fan shape. That levels out the bell shape somewhat.)

Broadcasting

When more than one nozzle is triggered by the sensor, the spot spray of that region is just a small section of a broadcast boom. The average dose is now related to the nozzle spacing, not the actual band width as it was for a single nozzle. The wider the section of nozzles that are activated simultaneously, the less inefficiency a wider individual pattern creates because it’s only wasted on the outside edges of the outside nozzles.

Clearly, a sprayer that sometimes functions as a single nozzle spot spray, and at other times as a broadcast boom requires some compromises. Monitoring the activation of nozzles and learning from the relative frequency of single vs multiple nozzle activations will be useful to optimize the configuration. But when boom height is constant, a good compromise solution is possible.

Suspended Booms

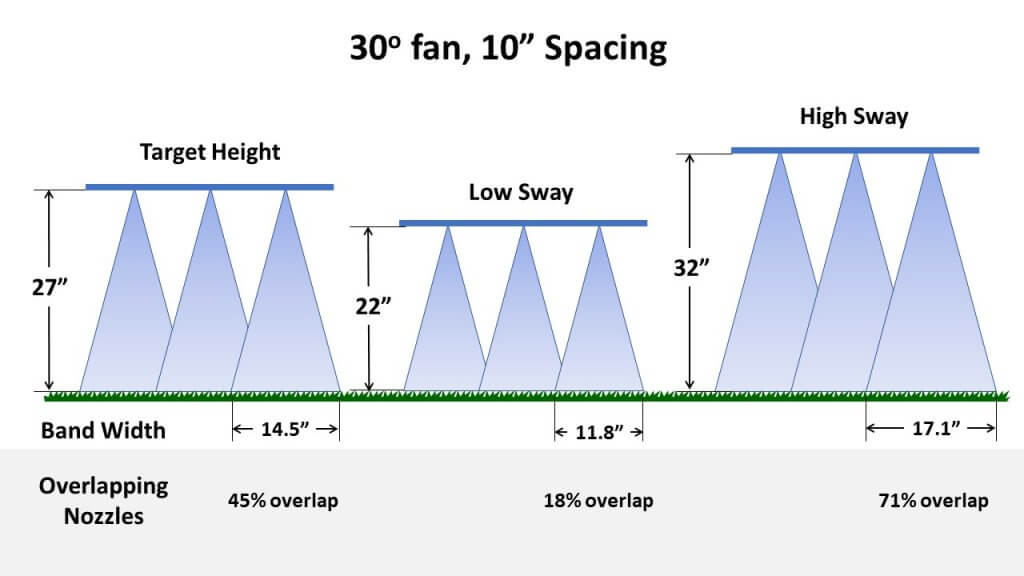

A more challenging situation arises from suspended booms that do not hold a consistent height. Let’s assume a boom height variance of 10” (5” in either direction), and a wish to retain 20% overlap at the lowest height to avoid misses from a 30 degree nozzle. The lowest height would have about a 12” pattern width, achieved at 22”. The boom would be set 5” higher, 27” (69 cm). At this height, a 30 degree fan would produce a band width of 14.5” (37 cm), producing a 45% overlap. If the boom sways up to 32” (81 cm), the pattern width would be 17.1” (43 cm).

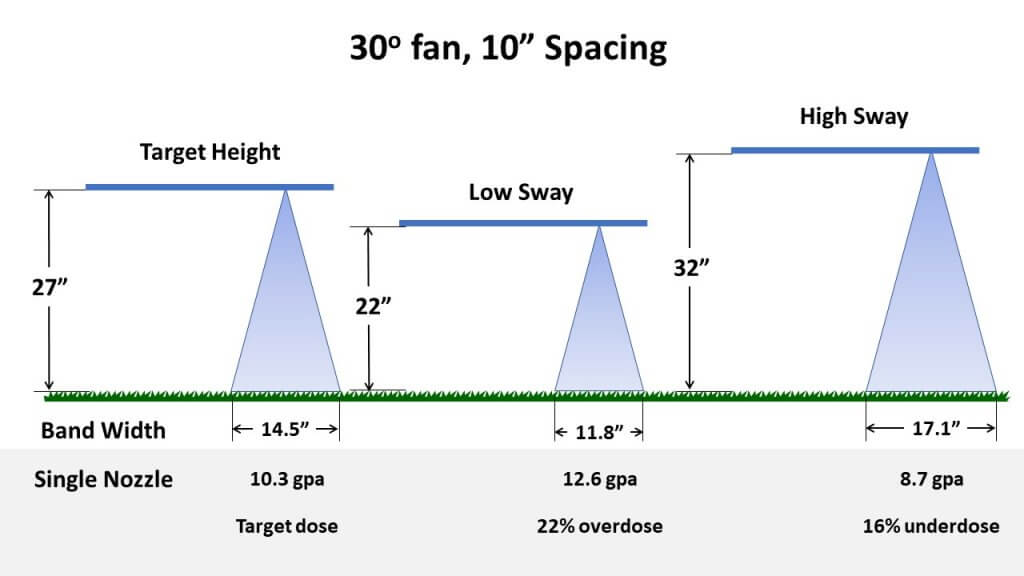

This is where it gets tricky. At suboptimal heights, the difference between a single band and a section of overlapping patterns increases. Do we calculate the tank mix for the rate a single nozzle delivers within its band, or for a set of nozzles activated simultaneously? If we knew that the majority of activations are for a set of two or more nozzles, we could opt to assume an application rate of a boom section with 10” spacing. An 03 nozzle at 40 psi and 10” spacing would apply 14.9 gpa (139 L/ha). But when a single nozzle is activated, the application volume in the 14.5” band is just 10.2 US gpa (95 L/ha), and the plants that triggered just a single nozzle would be under-dosed.

At the top of the sway (32”), a single nozzle’s wider pattern would deliver about 8.7 gpa (81 L/ha) , another 16% less spray volume than at 27”. At the low end of its sway, the band is 12” wide, applying about 12.4 gpa (116 L/ha) , 23% higher than the 10.2 gpa rate at the 27” boom height.

It’s clear that to take advantage of the potential savings of spot spraying, and to ensure good success with single nozzle activation, consistent and accurate boom heights are essential. I’m not sure how much more obvious a development priority can be.

Band Length

Spot sprays allow the user to select the length of band that the spray is activated for. Shorter band lengths require more targetting certainty. If booms and travel speeds are both low, an individual detected weed can be targetted accurately with relatively short band lengths because relatively little can happen to displace the spray during its short journey. But as booms and travel speeds are higher, the time that the spray arrives at the target is more difficult to predict and longer band lengths need to be programmed. For example, wind can push the spray off its target. Or the faster speeds impart more of a horizontal vector to the spray, causing it to land further away from the point of release.

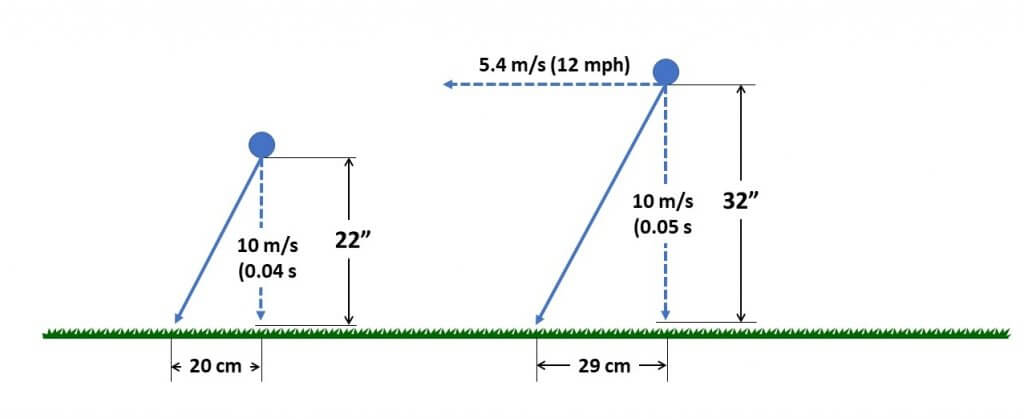

The variances in where the spray lands along the direction of travel depend on droplet speed and boom height. A conventional flat fan nozzle produces an initial droplet velocity of about 20 m/s. These droplets slow at a rate dependent on their size and whether they’re entrained in the spray plume. At 45 cm below the nozzle, larger droplets are still moving at 10 m/s. Smaller droplets are only moving at 1 to 2 m/s.

Let’s assume an average droplet speed of 10 m/s for the journey. At that speed, the spray takes about 0.05 s to travel the 0.7 m (27”) from nozzle to target. During that time, the sprayer going 12 mph (5.6 m/s) moves about 0.25 m forward, as do the larger droplets from the released spray. If the boom sways down to 22” or up to 32”, the distance travelled by the sprayer is 0.2 and 0.3 m, respectively. In other words, the band length would need a buffer of 10 cm to accommodate the variability of the beginning and end of the band.

Overall Efficiency

Are these numbers such a big deal? You might say that we’re already cashing in on some big savings here, so why sweat the details?

It’s the principle and the resources. If we’re talking about individual nozzle band width and its change with boom height, accommodating boom sway means applying more than necessary on average to avoid under-dosing when booms sway high. The examples used here show a potential dose variance of 40% with a boom sway of 10”, a modest assumption. That’s a big number to leave on the table. If we had a constant boom height, we could decide what overlap we wanted and minimize these losses.

One of the features on most spot sprayers is to turn on all nozzles of a section that exceed a certain boom height. While this prevents under-dosing and ensures an area is treated even when the sensor is outside of its optimal range, it is possibly an unnecessary use of product.

If we’re talking band length, adding 10 cm to a band length of 50 cm is 20% over-application. That can also add up.

The key to being efficient with spot sprays is accurate and consistent boom height. We know we can do that with a wheeled boom. But show me a suspended boom that can deliver on this, and I see an instant industry leader in spot spray application.