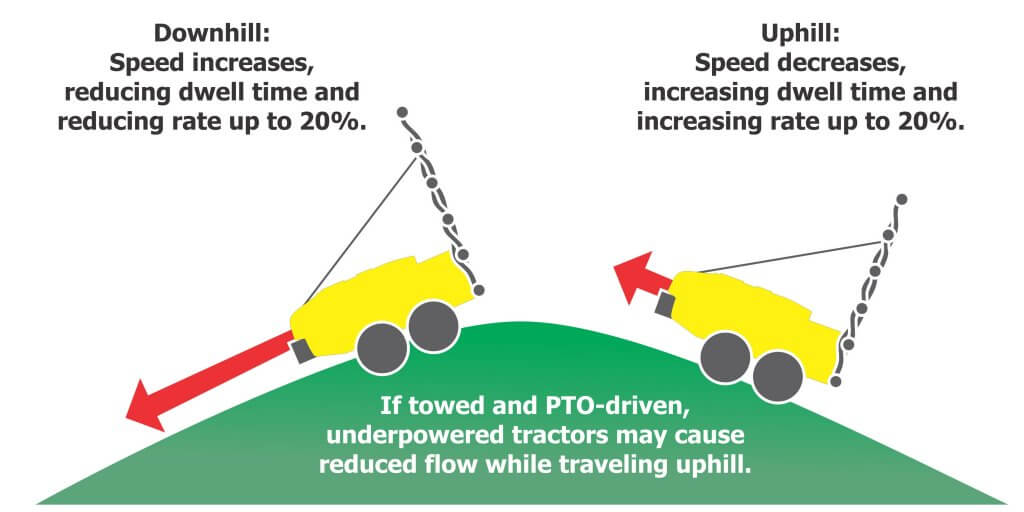

There are many advantages to using rate controllers, but their primary role is to maintain a constant application rate. All sprayers change speed on hills, at row-ends, or in response to surface conditions. Since flow from an uncontrolled sprayer is constant, the application rate varies significantly (up to 40% in hilly conditions). Rate controllers compensate for changing speed by adjusting flow.

Pesticide is not saved directly (since increased uphill rates already cancel out reduced downhill rates), but consider the pesticide label. Labels that list a range of rates are contingent on pest pressure and crop size, but also compensate for poor coverage from low-performing equipment. When coverage uniformity is improved, experience has shown that operators can safely spray at minimal rates.

Experience has also demonstrated that when coverage uniformity is improved, pack-out benefits follow. Even a modest improvement represents a quick return on investment. Equally important, a more consistent application reduces the risk of higher residue levels on the uphill and improves crop protection on the downhill.

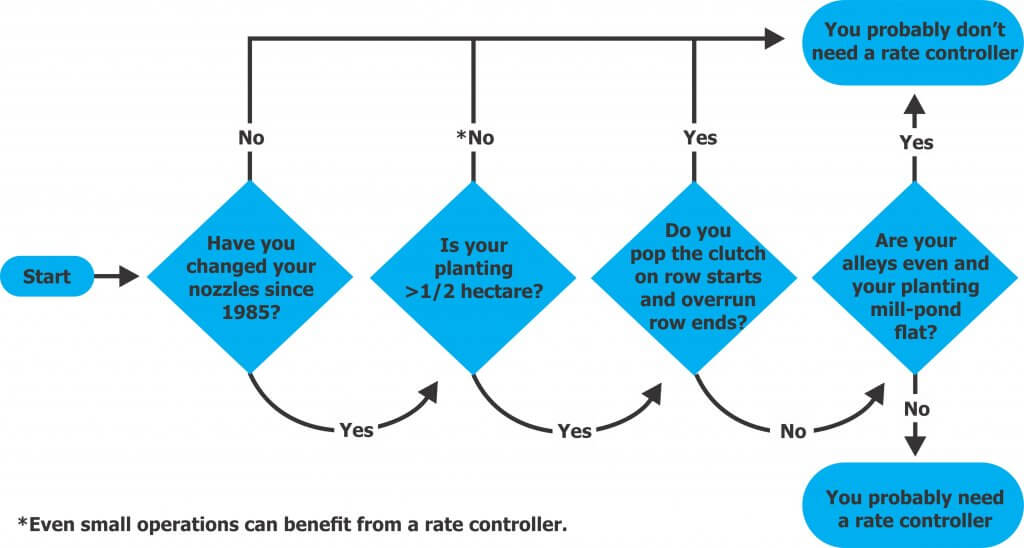

Now, if you are wondering if a rate controller is right for your operation, or if you should just stop reading now, consult this handy decision support matrix:

Rate controller categories

The following table categorizes controllers based on how they control flow. The categories are successively more expensive and complicated, but there’s commensurate value. For example, while not specified here, high-end rate controllers offer value-added features such as as-applied mapping (a powerful management tool).

| Description | Pros | Cons |

| Good: Monitors and adjusts pressure. Uses math to assume flow. | -Fewest moving parts. -Simple interface. -Lowest cost. | System monitors pressure, but does not register flow. For example, if nozzle flow is restricted, back pressure increases. The controller will compensate to correct pressure, implicitly reducing flow, but the operator is not alerted to the actual problem. |

| Better: Monitors and adjusts flow, not pressure. | Alerts operator to changes in flow. Operator usually sets the percent error threshold a little high to ignore transient changes. | System will not register pressure deviations. At threshold speed, pressure may drop too low. This can cause inconsistent check valve operation and spray pattern collapse. With tall booms, the top nozzles may close completely. |

| Best: Monitors flow and pressure and adjusts flow. | -Best likelihood of a consistent application. -Alarms or automatic compensation of flow and pressure (user sets hard stops). -Provides a low tank level warning. -Stores preset calibrations to quickly switch between blocks. | -Highest cost. -Steepest learning curve. -More “wire-wiggling”. -Operators often choose to over-apply at low speeds as a tradeoff for uniform output and consistent atomizer performance. |

Rate controller adoption and components

As we write this, less than 10% of air-assist sprayers have rate controllers. In the dark old days of the 1980’s, air-assist operators were ill-advised to install high flow, low pressure field sprayer controllers. That history of mismatched components and subsequent bad experiences continues to hinder widespread adoption.

Today’s components, however, are specific to air-assist sprayers and have made installations easier and more successful. Do your homework and speak with the manufacturer (not necessarily the local dealer) to ensure the controller, and all its components, meet your needs. Let’s describe the components so you’re prepared to have the conversation:

- Console

- Flow meter(s)

- Flow control valve (including electric boom shut-offs)

- Speed sensor

- Wire harness

Console

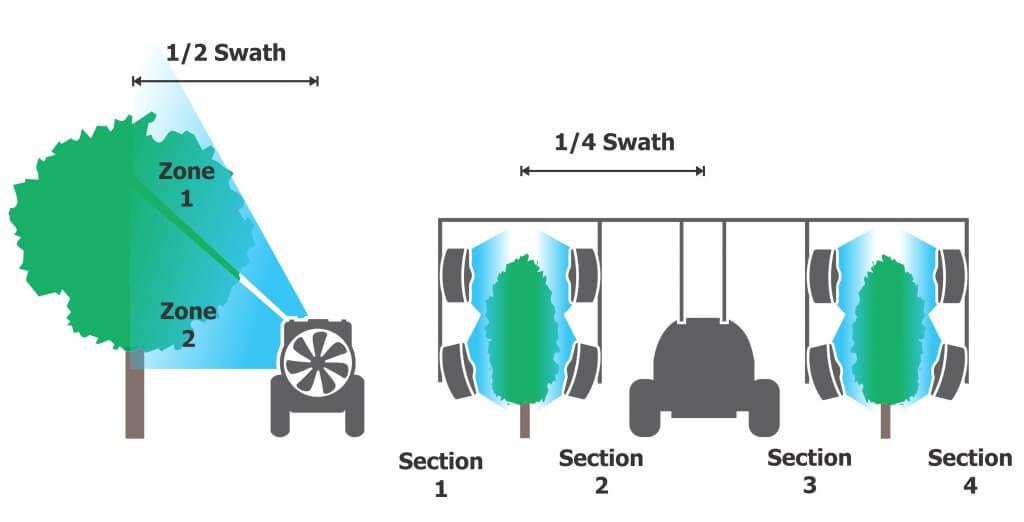

The console is the interface. The user enters criteria about the sprayer, the planting, and calibration data and receives information about sprayer performance. Select a console designed for air-assist sprayers and not field sprayers. Controllers intended for horizontal booms perceive swath in two dimensions, but air-assist controllers account for multiple vertical booms or boom sections in the swath (see the following figure).

Flow meter

With rate controllers, flow is detected by one or more flow meters positioned pre-manifold. The relief valve becomes more of a safety device, defining the high pressure limit and bypassing flow if required. Most rate controllers use a flowmeter with no ability to monitor pressure. While still effective, adding a pressure sensor ensures nozzles are operating in the desired pressure range.

Turbine or paddle meters are inexpensive and acceptably accurate. They require periodic cleaning because some chemistry can accumulate and interfere with their moving parts. Filtration helps to minimize this issue. Magnetic or ultrasonic meters have no moving parts, higher resolution, wider metering ranges and aren’t affected by the viscosity of the spraying solution or entrained foam. However, they are considerably more expensive than mechanical meters.

Flow control valve

Unlike boom control valves that are open or closed, flow control valves are capable of a range of adjustments. Valve actuation is controlled by 12 volt servomotors. The level of precision depends on the style of valve.

- Butterfly valves: Simple, inexpensive, and typically for pressures <10bar (150psi). Some have minor leak-by when closed. Control is less precise as the valve opens because the orifice gets geometrically larger. This gives a narrow metering range.

- Calibrated ball valves: Versions available for all pressures. May be simple flow through balls with similar metering limits to a butterfly. A better ball design is also available that offers a linear flow rate through the entire adjustment range, offering more stable rate control over the entire flow range. Several manufacturers offer these. All ball valves offer zero flow when closed.

Compared to field sprayers, air-assist sprayers travel slower and use lower flow rates. It is a mistake to employ valves intended for high-flow, high-speed sprayers.

- Speed: Valves are rated by connection size (½”, ¾”, etc.) and opening time (e.g. 1-14 seconds are common). Many rate controllers can be programmed to optimize adjustments for the speed and size of the valve.

- Precision: As control valves open over their 90° range, the ability to control flow is less precise. Slower valves give less precision, but greater stability.

- Size: Valve size should accommodate maximum flow and no more. If the valve is too large, it can only meter flow over the first few degrees of opening. For example, let’s say a valve capable of 200 L/min (50 gpm) and rated 1 second is used. Your sprayer meters 0-20 L/min (0-5 gpm). This means the whole metering range happens in the first tenth of a second. Even lightning-fast consoles will give unstable readings (aka hunting) as the computer overshoots the target in an effort to comply.

Control valves are “service parts”. Seals, moving parts and abrasive liquids mean they will require regular care and eventual replacement. It’s a wise precaution to make them accessible and easily removable. We suggest installing them with quick-connects (see top-right of the previous collage of rate controller components above) to make field-maintenance fast and easy.

Speed sensor

Speed can be based on GPS, engine tachometer readings, radar, or wheel rotations. Newer rate controllers may even take the speed directly from the tractor’s data feed. Price, reliability and crop conditions are all factors you should consider in the choice.

- GPS: Easiest to deploy, very accurate (especially RTK-GPS) and reasonably priced. However, overhead canopy can block satellite signals. Some controllers compensate for the GPS losses with sophisticated internal kinematic devices that measure the inertia of the sprayer and calculate speed when the GPS is not reliable.

- Wheel rotation speed sensors: An entry-level sensor, it’s typically a reed switch or Hall effect sensor that detects either the lug nuts or magnets installed on the rotating wheel. More magnets improve accuracy. Its exposure makes it prone to physical damage, and readings change with tire radius (which changes as the tank empties, on soft ground and with temperature). This is why wheel sensors are calibrated in the alley, with the tank half full and both tires at the same pressure.

- Radar speed sensors: Employing the Doppler effect to measure speed, radar is the most accurate sensor. They are unaffected by terrain, slope or tank volume. They can be mounted anywhere in sight of the ground. They are, however, the most expensive and are typically not repairable if they fail.

- Tachometer speed sensors: Largely obsolete, they measure the tractor’s tachometer speed and convert it to travel speed. Difficult to install and prone to the same inaccuracy as wheel sensors.

- Interface sensors: Relatively new, some rate controllers interface with tractor electronics to receive speed data. ISOBUS, the standard interface language that agricultural electronics are increasingly adopting, makes this data exchange more common.

Wire harness

It may seem we’re drilling deep to mention wires, but standards are changing. Many controllers employ traditional analog wiring, but they are being made obsolete by the newer ISOBUS option.

- Traditional Analog: Simple wires with automotive or custom plugs designed to match components. Relatively inexpensive and sometimes field repairable, analog wiring carries signal voltage (and power) to and from the controller to drive valves and receive analog sensor data. Communication is one-way: Sensor to controller, controller to valves.

- Modern ISOBUS: Bus systems are more like a computer network, where digital signals travel back and forth between the controller and each component. Components that require power are wired directly to a battery. This results in a greatly simplified harness. The controller’s single ISOBUS wire “daisy chains” all components to relay commands and receive status, which makes system monitoring and diagnosis easier and more effective.

Conclusion

Rate controllers are a worthy consideration for your existing or future air-assist sprayer. Assess your needs and work with a knowledgeable dealer or manufacturer that can assemble and install a system appropriate for your operation.