Nozzle choice can be overwhelming due to the large selection available from many suppliers. But nozzles are the most important part of the sprayer, being responsible for metering the liquid, atomizing it into droplets, and distributing it across the boom. Review this list for what’s available, then follow these general recommendations.

1. Choose a Coarse spray quality for a multi-purpose spray

All sprayer manufacturers voluntarily publish the spray quality of their nozzles at various flow rates and operating pressures. This information is available here from their websites, catalogues, or apps. The most popular tips for field sprayers are the air-induced and pre-orifice low-drift style, and these are typically operated between 30 and 90 psi. As a starting point, look for tips that produce a Coarse spray quality at an intermediate pressure of 60 to 70 psi. This seemingly high pressure is normal for air-induction style tips and provides some necessary travel speed range for self-propelled sprayers.

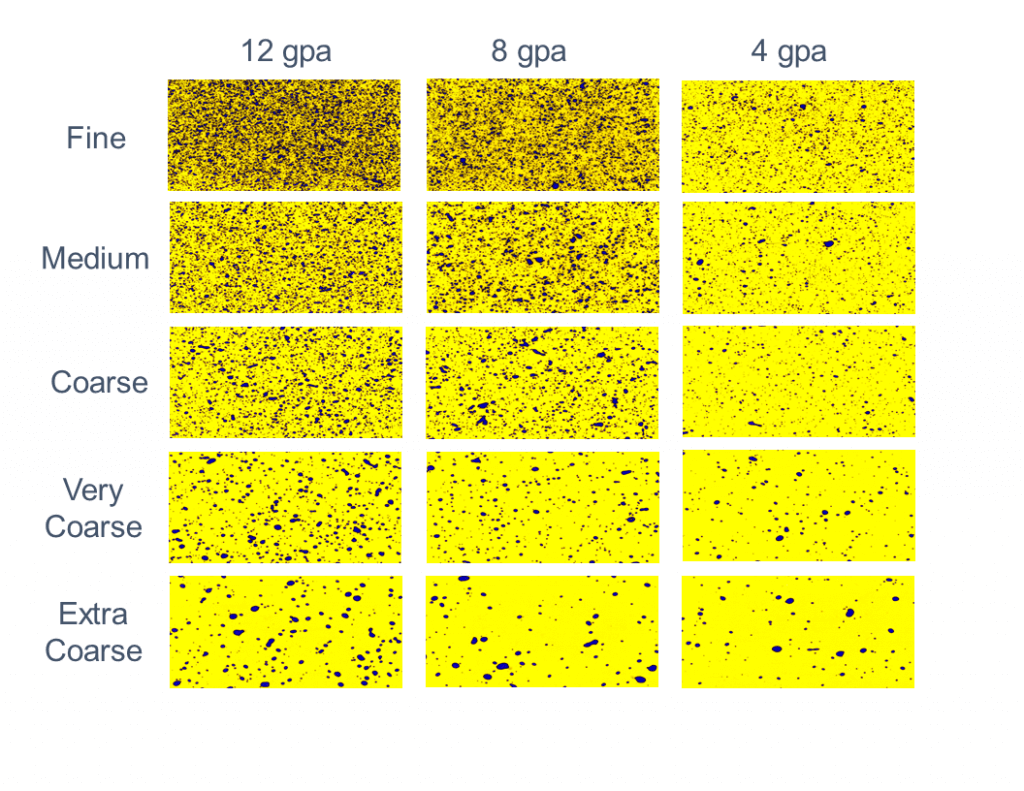

2. Match water volume to spray quality and crop canopy

Spray quality is a useful way to manage spray drift and coverage. The coarser your spray, the higher your water volume must be because you must have enough droplets per unit area to hit your target and provide enough droplet density on the leaves. This is most critical for pre-seed burnoff, where weeds are smallest, and where low-volume, very coarse sprays will likely miss weeds entirely. It is also important for contact herbicides (that require high droplet densities) and for grassy weeds, most of which have a hard time retaining very large droplets. Use at least 7 to 10 gpa for in-crop herbicides, 10 to 15 gpa for fungicides. The taller your crop canopy, the more leaves there are to cover and the more water is required.

3. Know and use the right pressure for your nozzle

Even a good nozzle won’t work well at the wrong pressure. Air-induced nozzles and some pre-orifice nozzles require higher pressures to operate properly. The most common reason for performance complaints is when the spray pressure of a low-drift nozzle is too low, resulting in poor spray distribution between nozzles (see next point). If your sprayer cannot produce sufficiently high pressures, you should not be using these nozzles. Use your spray pressure gauge as your speedometer, and aim for pressures in the middle of the nozzle’s recommended operating range. Higher pressures increase drift potential, but less so for pre-orifice and air-induced nozzles. These tables help size your nozzles for your travel speeds.

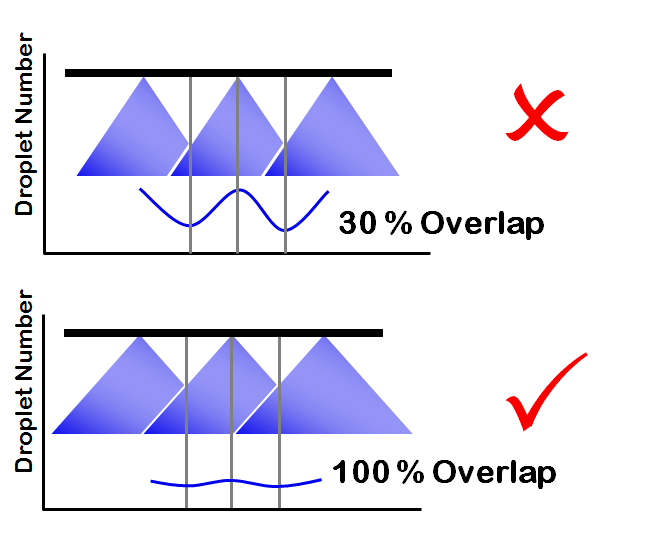

4. Ensure good patterns

Whereas finer sprays from conventional nozzles can re-distribute themselves with wind or turbulence, covering up poor patterns, the coarser droplets produced by low-drift sprays will go where they’re pointed. Therefore, there is only one chance to get uniform coverage across the boom. Before spraying, set your sprayer to your lowest expected spray pressure (say 30 psi) and your lowest expected boom height and inspect the spray pattern overlap. For low-drift sprays, try to achieve a nozzle pattern width that is twice your nozzle spacing at the target height. If necessary, adjust your boom height, increase pressure, or select wider angle nozzles. This will ensure that the coarsest droplets at the pattern edge are mixed in with the more abundant, finer droplets found in the middle of a pattern.

Visitor Rating: 4 Stars