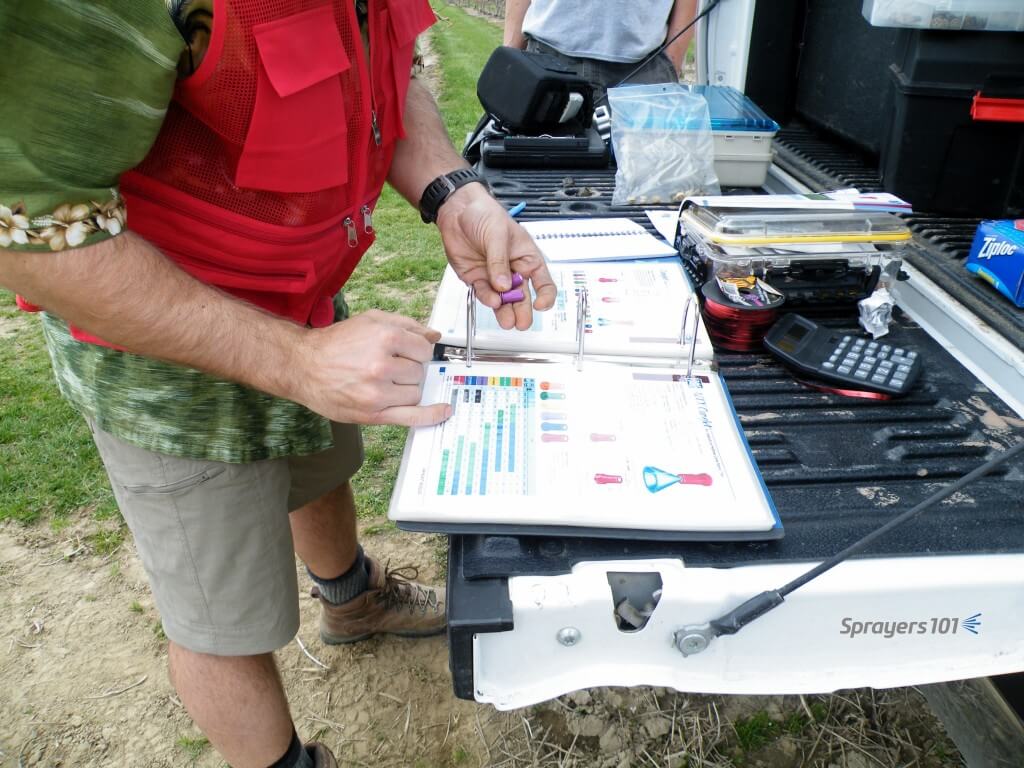

This article was co-written with Murray Thiessen, Consulting Agricultural Mechanic. Sprayer wheel assemblies should be cleaned and inspected as part of regular annual maintenance. Wheel bearing maintenance before long-term storage may prevent water from corroding the bearings. The exploded diagram details the parts found in a typical trailed air-assist sprayer wheel assembly. The following procedure was performed […]