This article is intended as a basic overview of what pesticide spray drift is and how to avoid it. If you want a more in-depth study of the physics of drift, head over here.

Defining Drift

Pesticide spray drift is the aerial movement, and unintentional deposit, of pesticide outside the target area. Aside from being illegal, there are a lot of compelling reasons for avoiding it. Drift can be measured in financial loss associated with wasted pesticide, wasted time and reduced crop quality/quantity. Plus, if an application is unsuccessful, the operator may have to re-apply, incurring further cost. Pesticide drift increases any risk of damage to human health, susceptible plants (e.g. adjacent crops), non-target organisms (e.g. wild and domestic animals, pollinating insects, etc.), the environment, and property.

We’ll limit our definitions to two forms of pesticide spray drift: Particle Drift and Vapour Drift.

Physical Drift is the initial off-target movement of pesticide droplets. This occurs at the time of application, and it is generally on a scale of tens-of-metres. There is a secondary component to physical drift wherein particularly small droplets (or the evaporated remains of droplets) stay aloft for longer periods of time, during which they can move laterally with wind or vertically with thermals and turbulence.

Vapour Drift is the off-target movement of pesticide vapours. This is a function of product chemistry (vapour pressure) and surface temperature. Rainfall (rewetting) can also affect vapour loss. If vapour gets caught up in a light breeze, moves downhill during a thermal inversion, or is redistributed in precipitation, movement is can be on a scale of kilometres.

Managing Drift

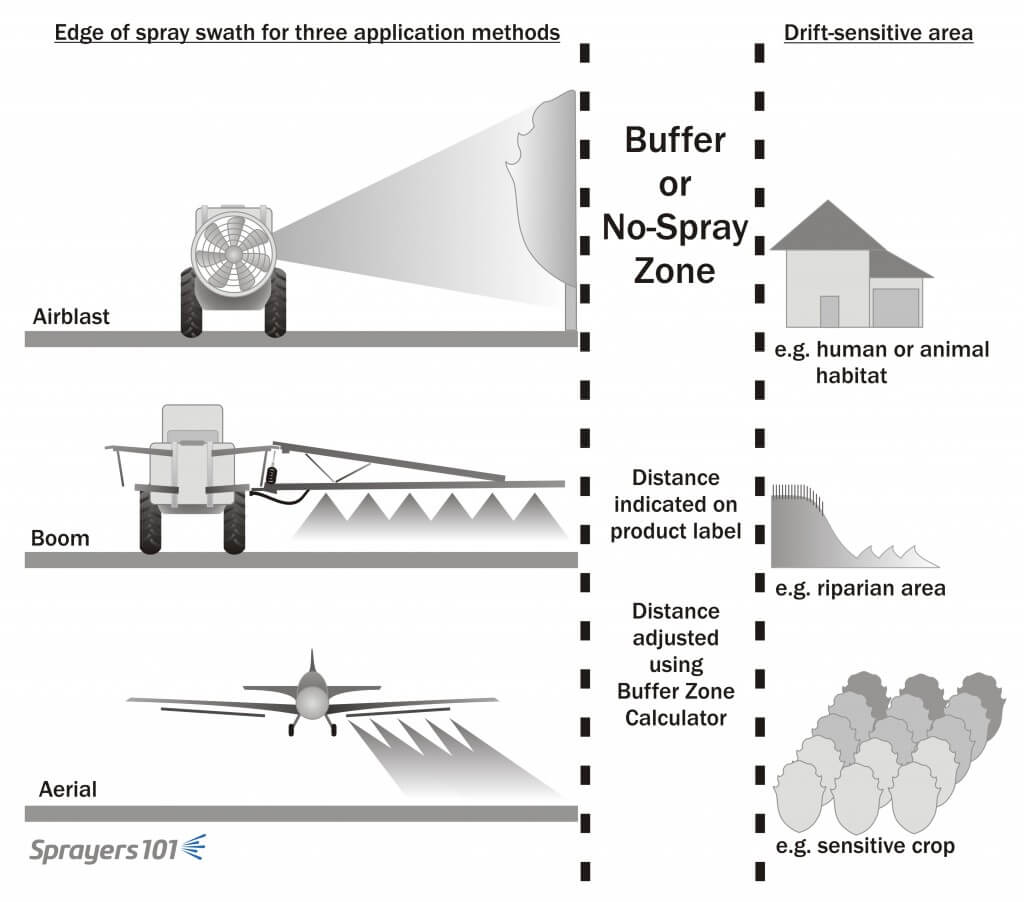

Drift cannot be entirely eliminated, but sprayer operators can greatly reduce the degree and impact. Much of what follows relates predominantly to particle drift from horizontal boom sprayers, but it’s never wrong to follow these best practices. Research and modeling have shown that the three biggest factors under the operator’s control are:

- Apparent wind speed (i.e. the sum of wind speed and travel speed)

- Boom height (i.e. release height)

- Droplet size (i.e. nozzle spray quality)

Therefore, the degree and impact of drift can be greatly reduced by following these guidelines:

- Reduce the distance between nozzle and target. For a herbicide application, that means lowering the boom to the lowest practicable height. There are exceptions, but a good rule of thumb is that the boom height should be approximately the same as the nozzle spacing.

- Use the coarsest effective droplet size, generally achieved through the use of drift reducing nozzles such as air induction.

- Work with the weather. Labels will specify appropriate weather conditions for spraying. Change sprayer settings to account for hot, dry and windy conditions or halt the job until conditions improve. Generally, avoid spraying when the weather is against you.

- Identify any vulnerable nearby crop, landscape or environmental area. Choose a spray day when winds are blowing away from these sites. Explore voluntary watchdog sites like DriftWatch to see if there are registered sensitive crops nearby. Planting windbreaks or utilizing riparian areas can also help manage wind and provide localized downwind protection.

- Observe labelled buffer zones and recommended sprayer settings. In Canada, using optimal sprayer settings in the right environmental conditions may reward the sprayer operator with buffer-zone reductions.

- Work with your neighbours. Let them know your intentions. For example, greenhouse growers need to be notified to close vents during morning spray times to avoid any possibility of drift.

- Understand the potential damage off-target herbicides can cause and make this part of your planning when selecting a herbicide. Where possible, choose herbicides with a low risk of volatility. Avoid products like dicamba near susceptible crops (grapes, tomatoes, peppers, sweet potato, tobacco, IP soybeans, etc.) or greenhouses. While not necessarily volatile, other synthetic auxins such as 2,4-D are extremely damaging to horticultural crops at very, very low doses.

Running an Airblast Sprayer?

For airblast sprayer operators, the environmental factors that affect drift are the same, but the rules for optimizing sprayer settings are slightly different. Droplet size is less of an issue, and in some cases droplet size cannot be controlled. Air settings are the primary tool for reducing drift potential.

- Adjust fan settings to produce the minimal effective air speed throughout the season.

- Use deflectors to channel air into, not over or under, the target.

- If possible, increase droplet size by using air induction nozzles or disc & core (or disc & whirl) nozzles that produce a coarser droplet size. Depending on canopy size, you could use them in every nozzle position, or only in highest nozzle positions.

- Any sprayer design the brings nozzles closer to the crop (e.g. tower or wrap-around designs) will reduce drift.

- Canopy sensors that turn boom sections on and off to match the size and shape of the canopy will reduce drift.

If You Suspect Drift

If you suspect your crops or property have been damaged by pesticide drift, follow these steps (The contact info is specific to Ontario, so substitute your local authorities). The following information is based on this article in ONFruit which focuses on herbicide drift. Drift onto an organic operation would not necessarily cause visual injury, but steps are similar.

1. Diagnose the problem

- Is there evidence of a spray application (agricultural or vegetative management such as roadside spraying)? Look for wheel tracks, weed symptoms, boom patterns and overlap on the headlands. Look for spray evidence in neighbouring fields, lawns, ditches, etc.

- Familiarize yourself with the symptoms of drift injury on your crops.

- Eliminate other possible causes. Disease, insects, nutrient deficiency, herbicide carryover, improper sprayer cleanout, and environmental stress can resemble drift injury.

- Are there damage patterns? In the case of physical drift, damage is more pronounced on the upwind side of the damaged area, tapering away with distance from the source. In the case of vapour drift, damage can be uniform throughout damaged area and not necessarily downwind from the source. Pesticides can also move in cold air drainage and in surface run-off from rain events. If damage is patchy, it may be something else, such as soil pH or carryover (look where sprayer starts and stops).

2. Contact the appropriate people

- Talk to your neighbour or the sprayer operator. Ask what was sprayed, when it was applied and who performed the application.

- Contact the Ministry of the Environment, Conservation and Parks District Office or Spills Action Center (SAC): 1-866-663-8477. The SAC is available 24/7 and they will then contact the appropriate Environmental Officer and pesticide specialist in your region. Local MECP offices can be found here.

- It is extremely important to report as soon as possible because the concentration of herbicide drops quickly within the plant. Do NOT wait until there are symptoms. Do NOT hesitate to call, even if you are unsure if it’s pesticide drift.

- MECP officers can do a site visit, take samples of tissue and soil, and have them analyzed for suspect pesticides. Where appropriate, the offending applicator may face charges under Ontario’s Pesticides Act. Charges will be pursued only if off label use is identified from the information gathered.

- Because of the wording of some of the labels and the difficulty of tracking down all the information needed, this has always been a very difficult thing to pursue in grower-to-grower drift incidents.

- The results from the MECP lab are available for the grower and, if enough information is collected, the grower is encouraged to pursue civil court if insurance and/or cooperation with the applicator does not work. According to the label of most pest control products, the applicator is liable for any damage caused by the misapplication of a pesticide.

- Contact your (crop) insurance adjustor and advise the applicator to contact theirs. However, do not rely on your crop insurance; Insurance companies may not provide coverage for drift incidents. It is prudent to determine if you are covered before you need to file a claim.

- Report the incident to the PMRA Voluntary incident reporting system

- Report the incident to the manufacturer of the pesticide product. See the label for the toll-free number. Labels can be found on the PMRA label search.

3. Document all details of the problem and consider lab analysis

- Collect spray records. This includes yours (to ensure it was not your application), and the potential offending applicators’.

- Collect weather records (temperatures, possible temperature inversions, wind speed, wind direction, rainfall) for the date of application).

- Take timestamped, geolocated photos (most smartphones include this information automatically, but check your settings). Repeat photos several times through the season.

- Document yield loss from the damaged area and an undamaged area. Choose a similar planting (same age, cultivar, rootstock, etc.). For perennial crops (e.g. vineyards, orchards, asparagus, berries) herbicides such as Group 4’s may necessitate documenting the effects for several years after the damage occurred.

- Laboratory analyses of herbicide levels in plant tissue are often necessary to confirm the presence of herbicides, although symptoms may be helpful in diagnosing which herbicides caused the problem.

- Research laboratories that will analyze crop samples for herbicide residues. Their requirements regarding sample size, labeling, storage, and shipping will vary, as will the list of pesticides they provide testing for and their minimal detection levels. Given the time-sensitive nature of pesticide detection, it would be prudent to know this information before need the service.

Applicator Liability

Anyone using pesticides is responsible for their safe application. For example, the Ontario Pesticides Act requires that licensed spray applicators carry a specialized liability insurance policy that provides appropriate coverage for their business. Operators who work on a “for hire” basis (e.g. a licensed spray applicator) or away from their own farm operation will need additional coverage. Where drift damages adjacent crops, insurance adjustors generally ask the following questions:

- Was the damage to the applicator’s own crop? If so, it is unlikely that there will be coverage under any insurance policy.

- Was the damage to a neighbour’s property? If so, the applicator’s liability policy may respond.

- Was the product being applied according to label directions?

Other Resources

Managing spray drift is everyone’s responsibility. Extremely low, and often invisible, amounts of spray drift can be very damaging; even long after the application. For more information about drift mitigation, watch the following videos and download a copy of this Factsheet.

What is Pesticide Drift?- Ontario Ministry of Agriculture and Food and Ministry of Rural Affairs (2011)

Equipment and Methods to Reduce Pesticide Drift- Ontario Ministry of Agriculture and Food and Ministry of Rural Affairs (2011)

Preventing Pesticide Spray Drift- University of Missouri Extension (2013)

Three simple ways to reduce drift. Thanks to Real Agriculture for filming and editing! (2014)

Drop the boom and increase droplet size to reduce drift – Real Agriculture (2023)

Visitor Rating: 4 Stars

Visitor Rating: 5 Stars

Visitor Rating: 5 Stars