This article was co-written with Jennifer Llewellyn, former OMAFA Nursery Crop Specialist With more and more bio-rational products on the market, crop protection methods may require reassessment. Certain products require exacting water quality, cannot tolerate residues, and have half-lives that are both time- and temperature-critical. We’ve been getting questions about sprayer compatibility with some of […]

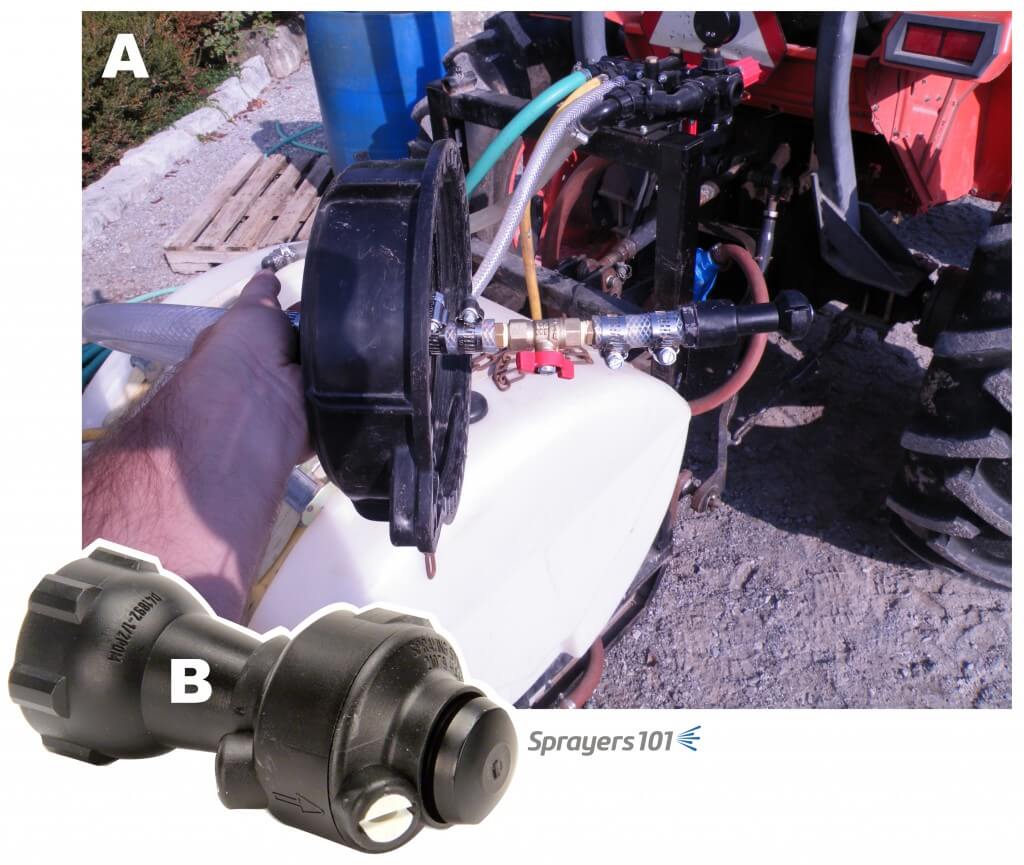

Read More… from Circulating Spray Mix Through a Tank-Rinse Nozzle Maintains Nematode Concentration