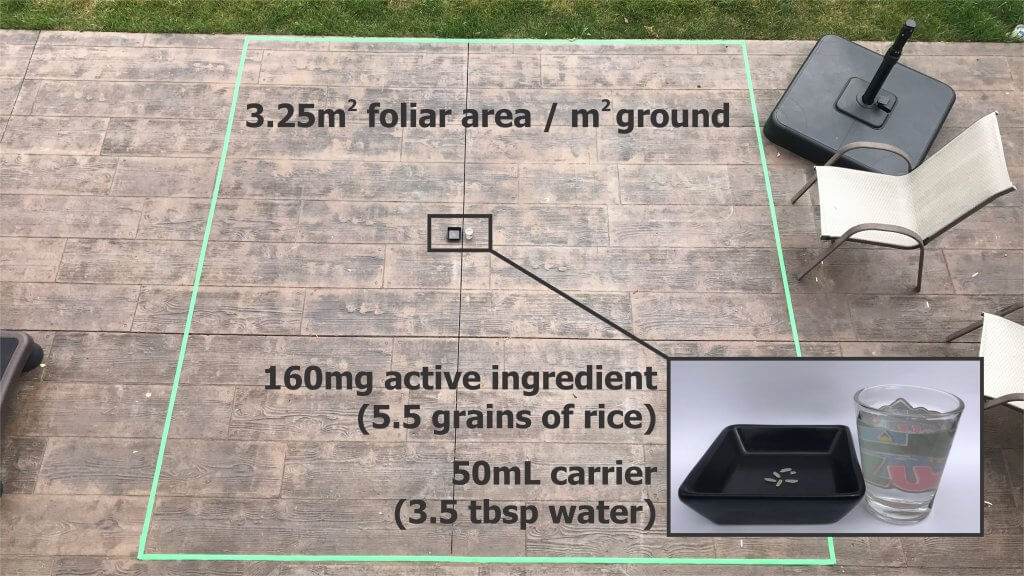

This short article is a thought exercise designed to give some perspective on chemical rates, carrier volumes and the foliar area we expect them to protect. Imagine we are spraying the fungicide Captan on highbush blueberry. In Canada, the label rate is to apply 2kg/ha (28.5oz/ac) of planted area. Captan is 80% active ingredient, so […]